A control method for improving the billet discharge efficiency of the heating furnace

A control method and heating furnace technology, which is applied in the field of steel rolling, can solve the problems of affecting operation efficiency and output, large interval time control deviation, and prone to steel stacking accidents, so as to avoid steel stacking accidents, reduce labor costs, and improve billet output. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

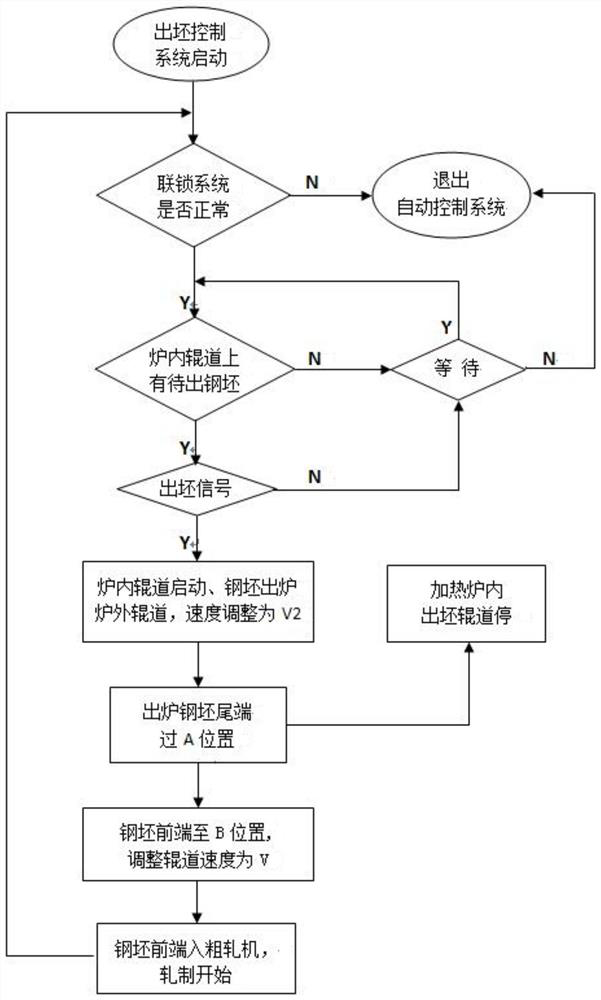

[0036] A control method for improving the billet discharge efficiency of a heating furnace, comprising the steps of:

[0037] ——Set the rolling cycle T of a single billet, that is, the time between the beginning of rolling of the front billet and the start of rolling of the rear billet;

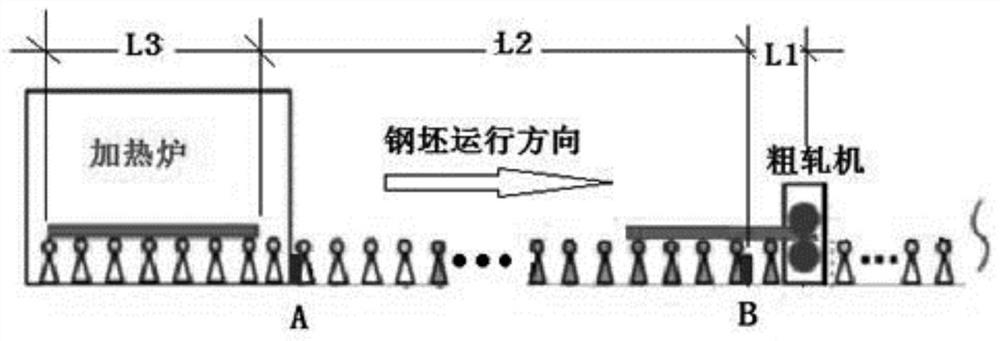

[0038] ——Install the first detection switch at point A of the exit of the heating furnace to detect the tail end of the billet, and install the second detection switch at point B at the rear of the roughing mill to detect the front end of the billet to be rolled;

[0039] but:

[0040] T=T3+T1;

[0041] T3=L3 / V

[0042] V2=L2 / T3

[0043] L3 is the length of billet;

[0044] T3 is the rolling time of a single billet;

[0045] L1 is the distance from point B to the roll center of the roughing mill, which can be set according to the requirements of the rolling process;

[0046] V is the rolling speed of the billet in the roughing mill, which is a fixed value, and the running speed of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com