Roughing mill level value giving method, device and system

A technology with a given device and level value, applied in the field of metallurgy, can solve the problems of scrapping of intermediate billets, stacking accidents, slab head deviation, etc., to eliminate differences, avoid scrapping accidents, and avoid sickle bending big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

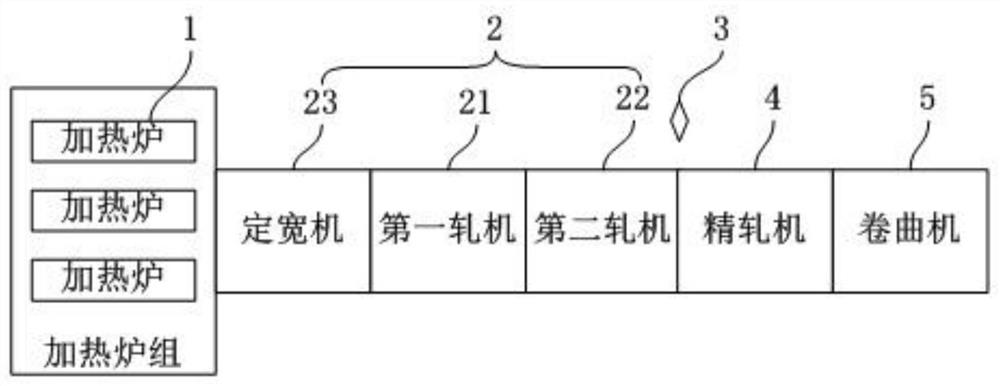

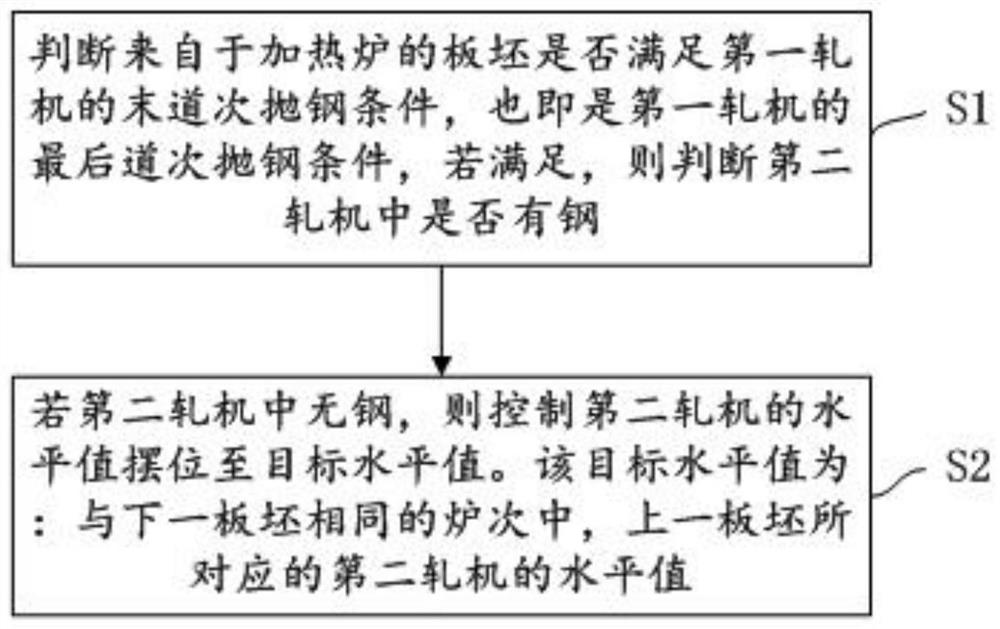

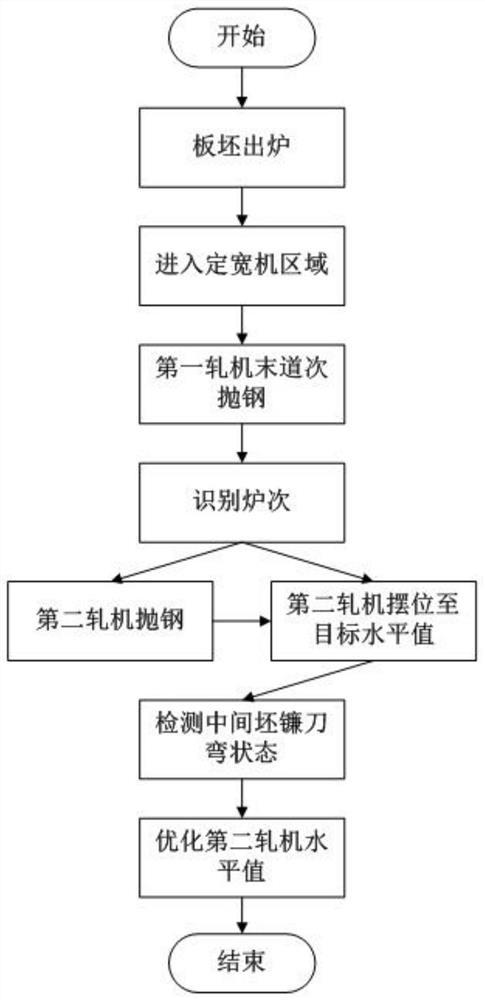

[0031] The invention provides a method for setting the level value of a roughing mill, which is applied to figure 1 The hot continuous rolling mill shown in the figure includes a plurality of heating furnaces 1 and rough rolling mills 2 arranged in sequence. In an embodiment, the multiple heating furnaces 1 may include three regenerative heating furnaces and one conventional heating furnace, and the rough rolling mill 2 includes a first rolling mill 21 and a second rolling mill 22 . The rough rolling mill 2 also includes a width-sizing machine 23 (i.e.: SSP) arranged at the outlets of a plurality of heating furnaces 1, and a finishing mill 4 and a coiler 5 are arranged in turn at the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com