Rough rolling vertical roll shallow pass treatment method

A vertical roll and air-pass technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of unreasonable process parameter setting, affecting strip width control, stacking accidents, etc., to avoid production capacity. Loss, saving process input, ensuring the effect of finished product width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

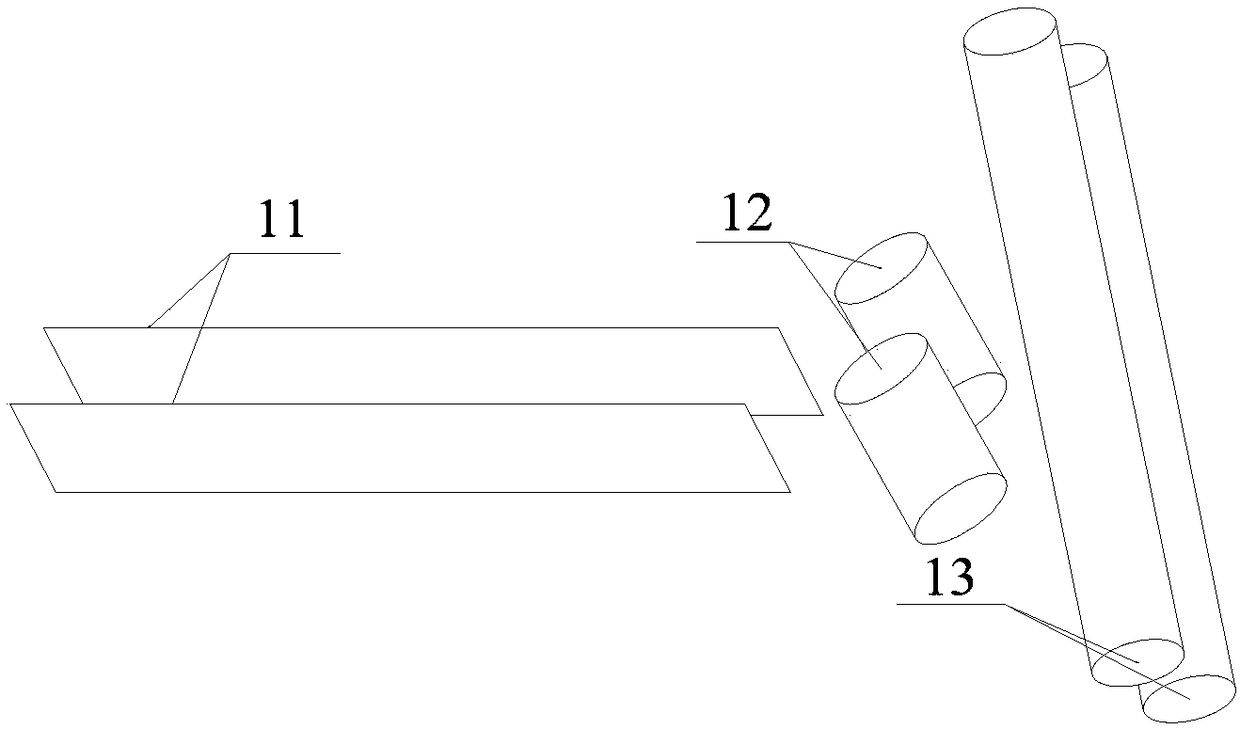

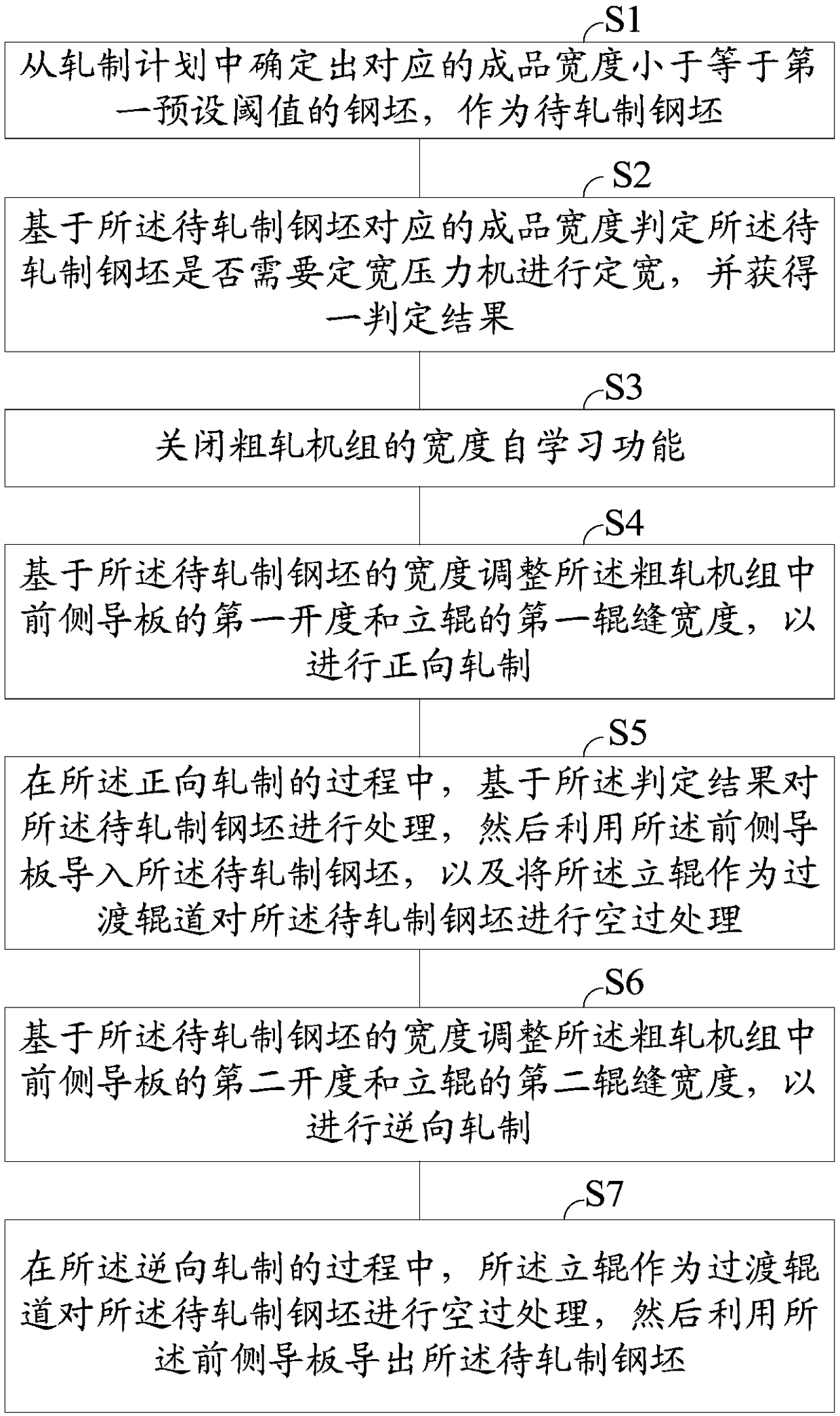

[0029] This embodiment provides a rough rolling vertical roll passing method, which is suitable for reversing rolling mills such as semi-continuous and three-quarter continuous. figure 1 It is a structural schematic diagram of a rough rolling unit in the reversing rolling mill, and the rough rolling unit includes a front guide plate 11 , vertical rolls 12 and flat rolls 13 . Wherein, the front side guide plate 11 is a side guide plate located before the vertical roll 12, which is used to make the steel billet to be rolled enter the rolling mill along the rolling center line to play the role of centering; the vertical roll 12 is used to place The steel billet to be rolled is rolled to a width meeting user requirements; the flat roller 13 is used to roll the steel billet to be rolled to a thickness meeting user requirements. figure 2 It is a schematic flow chart of the rough rolling vertical roller emptying method, and the rough rolling vertical roller empty passing method incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com