Tail pressing looper

A looper and tail-type technology, applied to bending workpieces, metal processing equipment, metal rolling, etc., can solve problems such as easy whipping and splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

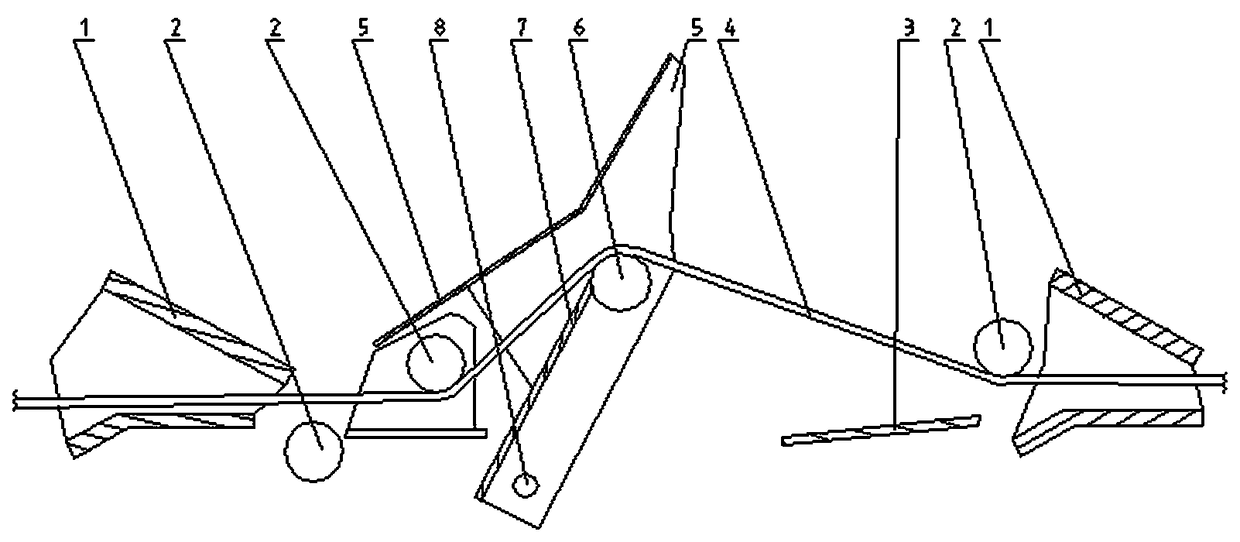

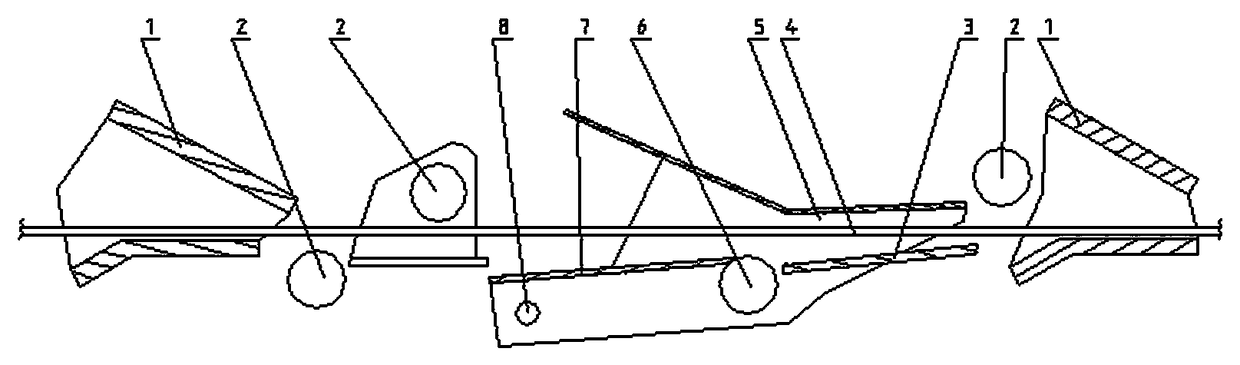

[0009] like figure 1 , figure 2 As shown, the tail-pressing type looper of the present invention mainly includes a looper roller 6, a movable guide plate 7, a fixed guide roller 2, and a looper shaft 8. The looper guide box 5 that doubles as the looper arm is housed on the looper shaft 8, the looper roller 6, the movable guide plate 7. The looper guide box 5 is a groove structure with a lower opening.

[0010] like figure 1 , figure 2 As shown, in order to enable the looper guide box to better cover the tail of the rolled piece 4, a lower guide plate 3 that can be covered by the head of the looper guide box 5 is also installed on the lower right side of the looper roller 6. .

[0011] like figure 1 , figure 2 As shown, the fixed guide roll 2 assists the looper roll 6 to adjust the stable tension of the rolling piece 4 during the rolling process. At the same time, when the looper roller 6 is at the lowest position, the fixed guide roller 2, the guide box 1, the loope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com