Hot rolling process of non-oriented silicon steel

An oriented silicon steel and process technology, applied in the direction of metal rolling, metal rolling stand, metal rolling mill stand, etc., can solve the problem of non-oriented silicon steel strip head narrowing, etc., to prevent the end from widening. The effect of large, reduced width deviation, and reduced trimming amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

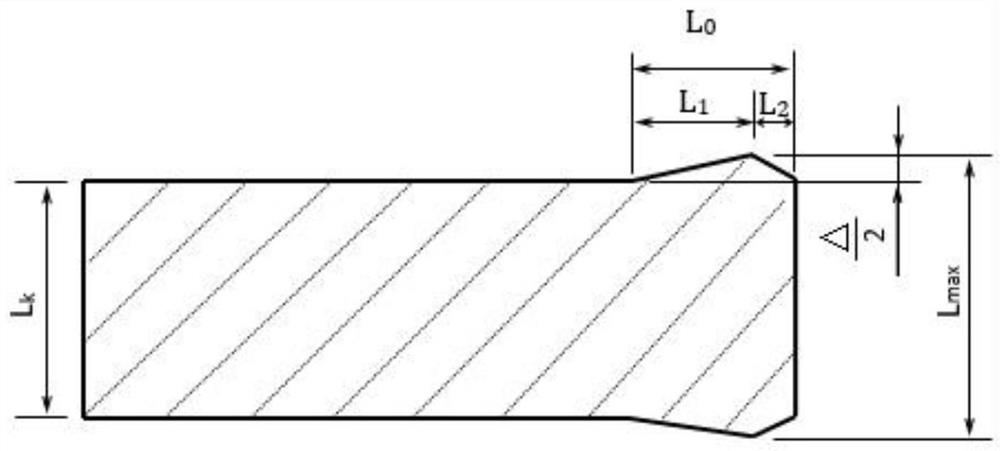

[0037] refer to figure 1 As shown, a kind of hot rolling process of non-oriented silicon steel, the specific steps are as follows:

[0038] Step 1: The mass percentage of the main chemical components of the billet is C: 0.0026; Si: 0.61; Mn: 0.41; P: 0.015; Al: 0.15; others are Fe and inevitable impurity elements. According to empirical formula A r3 =901-325C-92Mn+33Si+287P+40Al-20Cr Calculated A r3 =893°C.

[0039] Step 2: The temperature of the slab entering the furnace is 630°C, and the heating temperature of the slab is 1160°C;

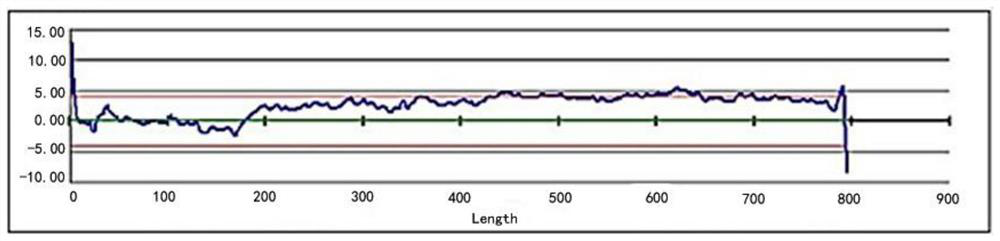

[0040] Step 3: The deformation rate of the last pass of the rough rolling mill is 33.3%, the rolling temperature is 1038°C, the thickness of the intermediate billet is 43mm, and the width of the intermediate billet is L k =1050mm, blank width is 1080mm, intermediate blank vertical roll width reduction is 30mm, set L 0 =8000mm, L 2 =400mm, L 1 =L 0 -L 2 =7600mm. During rolling, the L 2 The vertical roll gap in the length range is defined...

Embodiment 2

[0046] refer to figure 1 As shown, a kind of hot rolling process of non-oriented silicon steel, the specific steps are as follows:

[0047] Step 1: The mass percentage of the main chemical components of the billet is C: 0.0021; Si: 1.35; Mn: 0.43; P: 0.018; Al: 0.27; others are Fe and inevitable impurity elements. According to empirical formula A r3 =901-325C-92Mn+33Si+287P+40Al-20Cr Calculated A r3 =921°C.

[0048] Step 2: The temperature of the slab entering the furnace is 610°C, and the heating temperature of the slab is 1150°C;

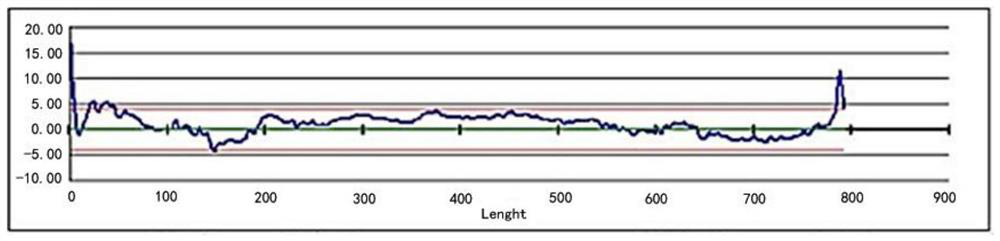

[0049] Step 3: The deformation rate of the last pass of the rough rolling mill is 33.3%, the rolling temperature is 1035 ° C, the thickness of the intermediate billet is 42 mm, and the width of the intermediate billet is L k =1250mm, blank width is 1270mm, intermediate blank vertical roll width reduction is 20mm, set L 0 =12000mm, L 2 =400mm, L 1 =L 0 -L 2 =11600mm. During rolling, the L 2 The vertical roll gap in the length range is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com