Effective method for solving problem of hot rolling coiling indentations

A hot-rolled coil and indentation technology, which is applied in tension/pressure control, rolling force/roll gap control, tail end control, etc., can solve the problems of insufficient indentation analysis, rigid control methods, error correction tracking, etc. , to achieve the effect of eliminating indentation defects, avoiding stacking steel accidents, and preventing error correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

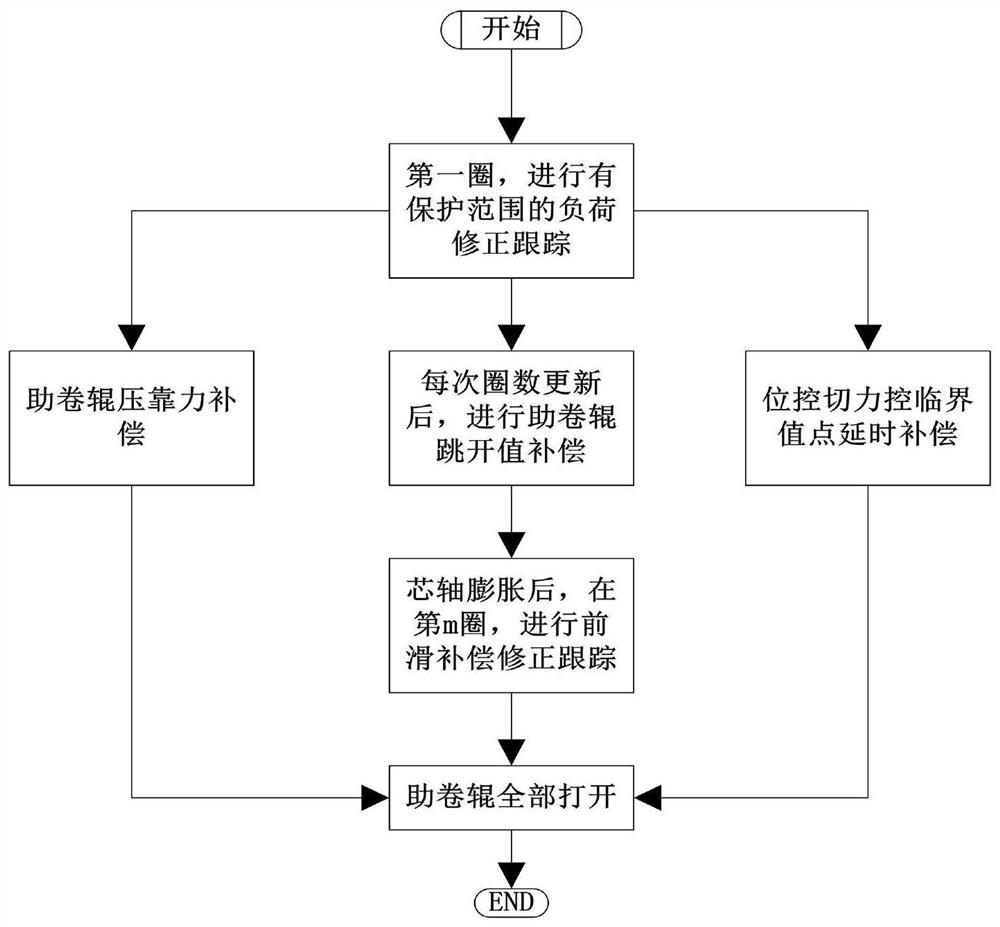

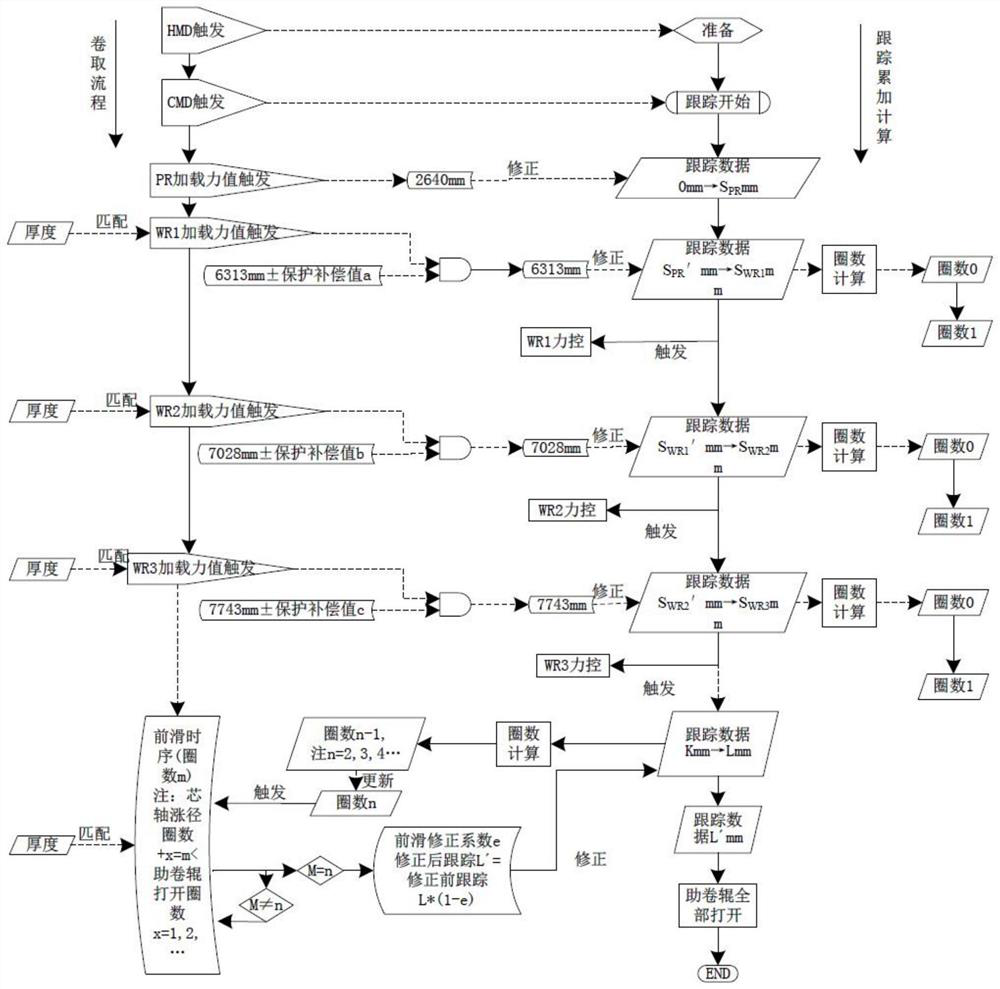

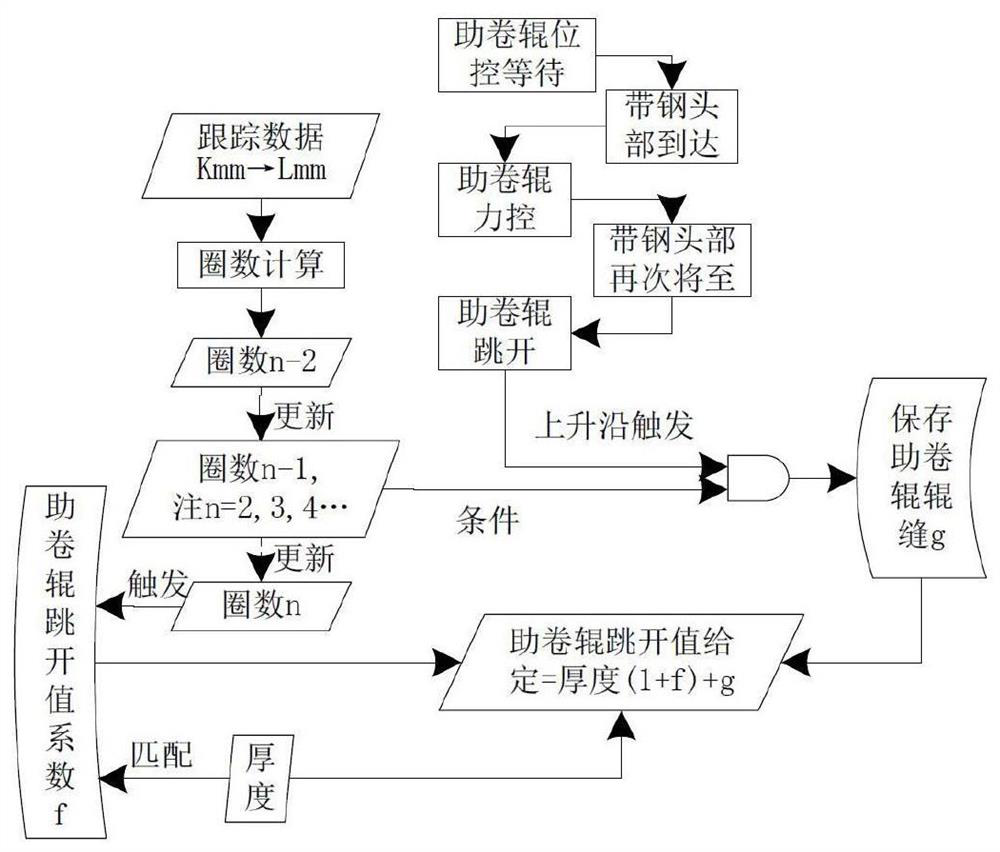

[0034] Such as Figures 1 to 5 As shown, an effective method to solve the problem of coil indentation in hot rolling

[0035] S1. Strip head tracking data correction

[0036] S1.1 Pinch roll (PR) tracking correction: before the strip head leaves the finishing mill and is about to enter the coiler, it first passes through the hot metal detector (HMD) to trigger the preparation signal; then passes through the cold metal detector (CMD), Trigger head tracking calculation; the strip head passes through the pinch roller, and the pinch roller triggers the loading signal through force value feedback, and the tracking data is corrected in time according to the formula SPR'=SPR-△, where SPR is the instantaneous tracking value before correction, SPR' is the corrected instantaneous tracking value, △=SPR-2640mm, and the measured distance from the bottom of the cold metal detector to the lower pinch roller is 2640mm.

[0037]S1.2 Tracking correction of the first lap of the winding aid rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com