A Method for Eliminating Indentation Defects of Furnace Roller in Continuous Annealing Furnace

A continuous annealing furnace and annealing furnace technology, applied in the direction of furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of consuming manpower, material resources and time, and the inconvenience of stable production, so as to reduce the loss of product degradation, reduce energy and medium consumption, and avoid complex The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

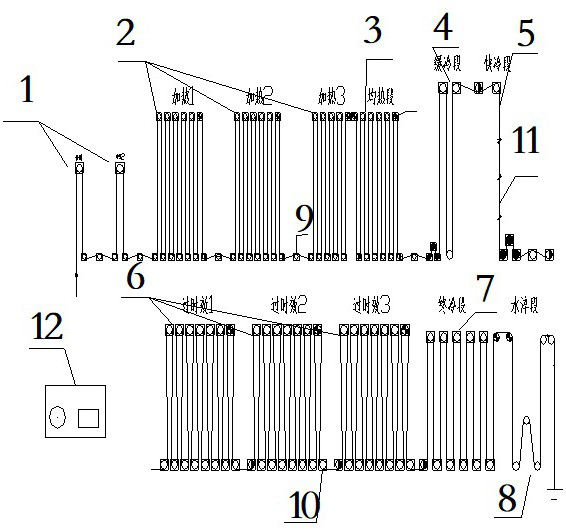

[0030] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

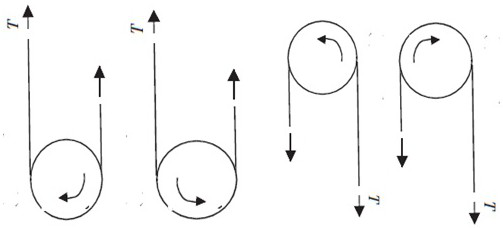

[0031] A method for eliminating indentation defects of furnace rolls in a continuous annealing furnace, comprising the steps of: formulating a quick lookup table for the indentation area of a turning roll in a continuous annealing furnace and a quick lookup table for the position of a turning roll in a continuous annealing furnace, and measuring the distance of the indentation defect on the surface of a strip steel , compared with the quick look-up table of the indentation area of the steering roll of the annealing furnace, determine the area where the indentation defect of the continuous annealing furnace furnace roll occurs; then use low temperature and small tension to make the shape of the indentation of the furnace roll smaller or disappear, and calculate the resulting indentation furnace The distance between the roll and the reference point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com