Method and device for tracking head part of strip steel

A technology for tracking strips and strips, applied in the field of metallurgy, can solve the problems of strip head tracking failure, reduced generation efficiency, and steel stacking accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In order to have a clearer understanding of this technical solution, the coiling process of the strip steel is firstly introduced here. Generally speaking, after the strip comes out of the finishing stand, it passes through layer cooling, flying shear, metal detector (hot metal detector or cold metal detector), pinch roll and coiler in sequence.

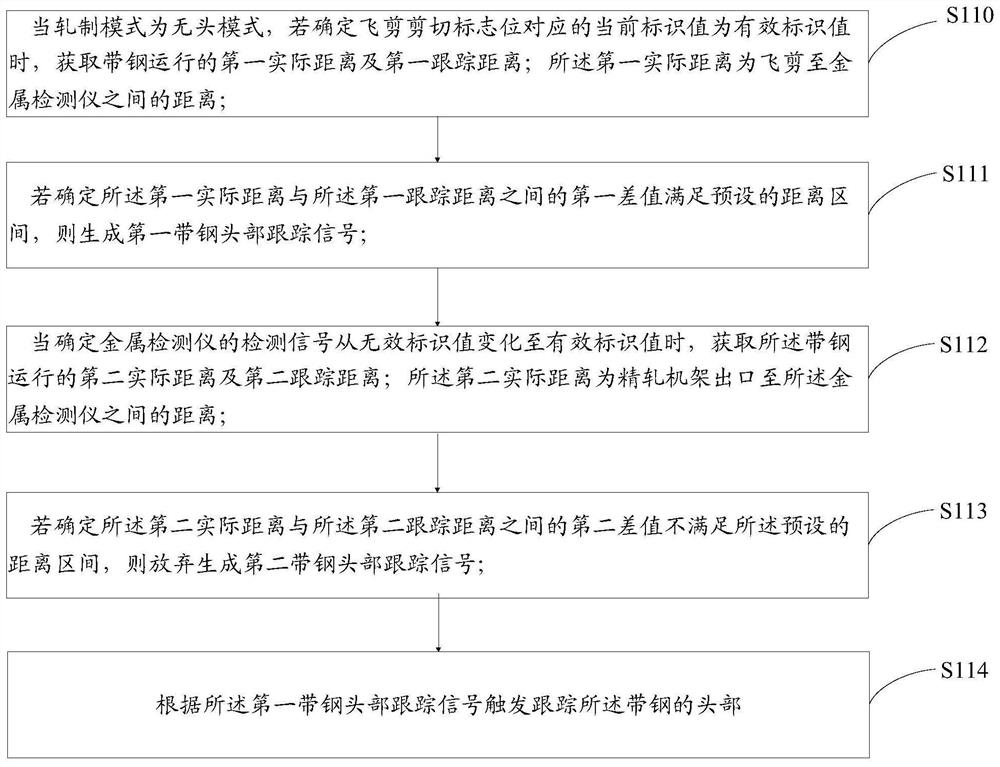

[0055] That is to say, after the steel strip comes out of the finishing stand, it is cooled, cut into multiple pieces of steel strip by flying shears, and then passes through the metal detector, and each piece of steel strip is sent into the coiler by pinch rollers for further processing. coiled. In order to accurately identify the head of the strip and avoid steel stacking accidents, this embodiment provides a method for tracking the head of the strip, such as figure 1 As shown, the method includes the following steps:

[0056] S110, when the rolling mode is the headless mode, if it is determined that the current identificati...

Embodiment 2

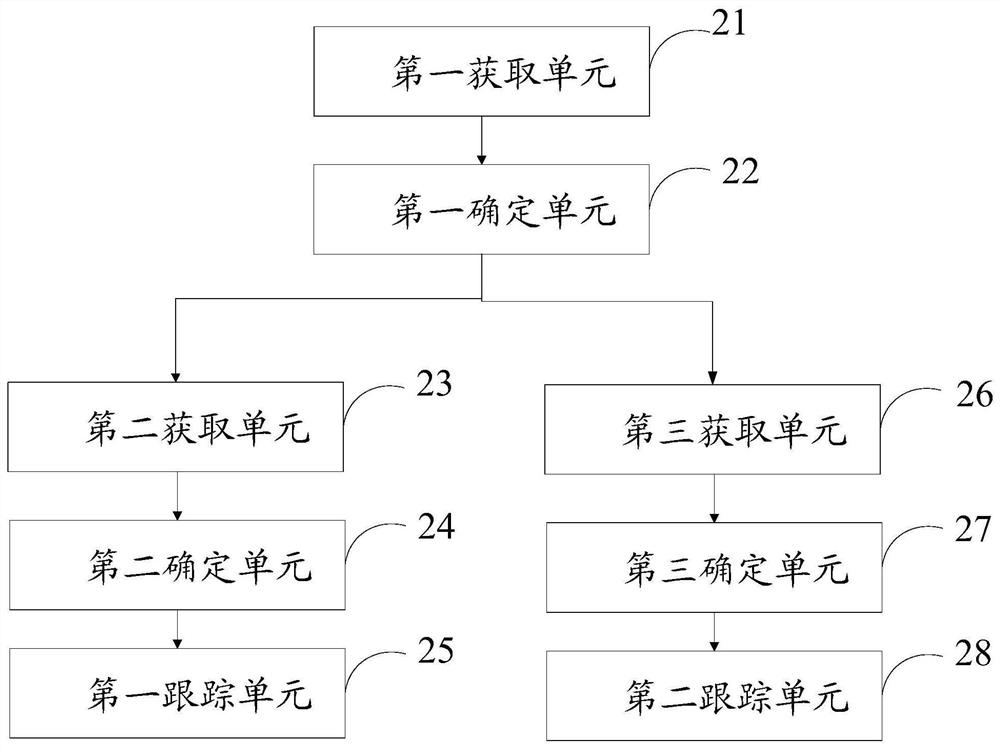

[0095] Based on the same inventive concept as in Embodiment 1, this embodiment also provides a device for tracking the strip head, such as figure 2 As shown, the device includes:

[0096] The first acquisition unit 21 is used to obtain the first actual distance and the first tracking distance of the strip running if the rolling mode is the headless mode, if it is determined that the current identification value corresponding to the flying shears shear flag is a valid identification value ;The first actual distance is the distance between the flying shears and the metal detector;

[0097] The first determination unit 22 generates a first strip head tracking signal if it is determined that the first difference between the first actual distance and the first tracking distance satisfies the preset distance interval;

[0098]The second acquisition unit 23 is used to obtain the second actual distance and the second tracking distance of the strip running when the detection signal o...

Embodiment 3

[0137] In practical application, when using the method provided in Embodiment 1 and the device provided in Embodiment 2 to coil the strip steel on a certain production line, the realization is as follows:

[0138] In the process of rolling the steel strip, the received rolling mode is identified as 1, indicating that it is a headless mode. When the strip head comes out of the finishing mill, the tracking function of the strip head will be started.

[0139]If it is determined that the current identification value corresponding to the flying shears shear flag is an effective identification value (such as when the current identification value is 1), it is necessary to obtain the first actual distance and the first tracking distance of the strip steel operation at this time; the first actual distance It is the distance between the flying shears and the metal detector. Wherein, the first actual distance is 5.5m.

[0140] Here, the first tracking distance may be determined accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com