Polarizer-protecting film, and polarizing plate and image display device each comprising polarizer-protecting film

一种保护膜、偏振片的技术,应用在偏振元件、运输和包装、化学仪器和方法等方向,能够解决产生粘连等问题,达到防止褶皱、卷取性优异、抑制粘连的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] (production of polarizer)

[0111]A polyvinyl alcohol film having a thickness of 75 μm was immersed in warm water at 28° C. for 60 seconds to swell. Next, it is dipped in an aqueous solution containing iodine and potassium iodide (weight ratio 1:10), stretched to 3.3 times, and dyed so as to achieve a predetermined monomer transmittance. Then, immerse in an aqueous solution containing 3% by weight of boric acid and 2% by weight of potassium iodide for 10 seconds, and stretch in an aqueous solution containing 4% by weight of boric acid and 3% by weight of potassium iodide at 60°C to make the stretching ratio The total is 6.0 times. Then, the obtained stretched film was immersed in an aqueous solution containing 5% by weight of potassium iodide for 10 seconds, and dried in an oven at 40° C. for 3 minutes to obtain a polarizing plate with a thickness of 30 μm.

[0112] (Production of (meth)acrylic resin film)

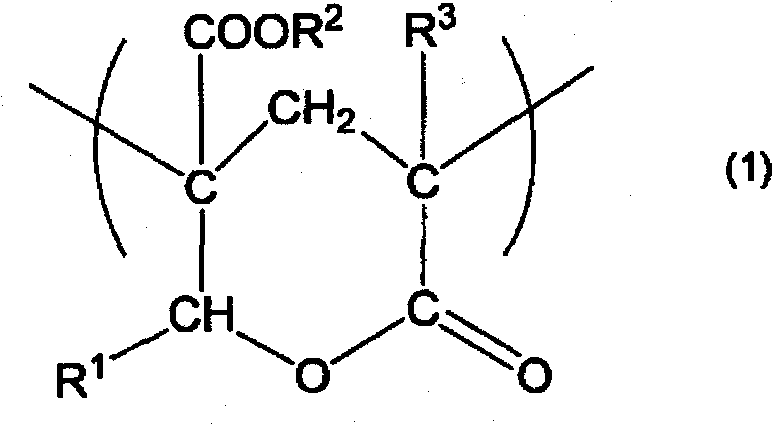

[0113] Will [have the following general formula (1) in R 1...

Embodiment 2

[0128] A polarizing plate was produced in the same manner as in Example 1 except that the compounding amount of colloidal silica was 0.32 g at the time of preparation of the easily adhesive composition.

Embodiment 3

[0130] A polarizing plate was produced in the same manner as in Example 1, except that the compounding quantity of colloidal silica was 0.21 g and the compounding quantity of pure water was 76.7 g at the time of preparation of an easy-adhesive composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com