Fiber composed of carbon nanotubes and its production method

A carbon nanotube and fiber technology, applied in the field of CNT, can solve the problems of uneven thickness, CNT fiber roundness, uneven thickness, etc., and achieve the effect of small uneven thickness, good coilability, and high roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

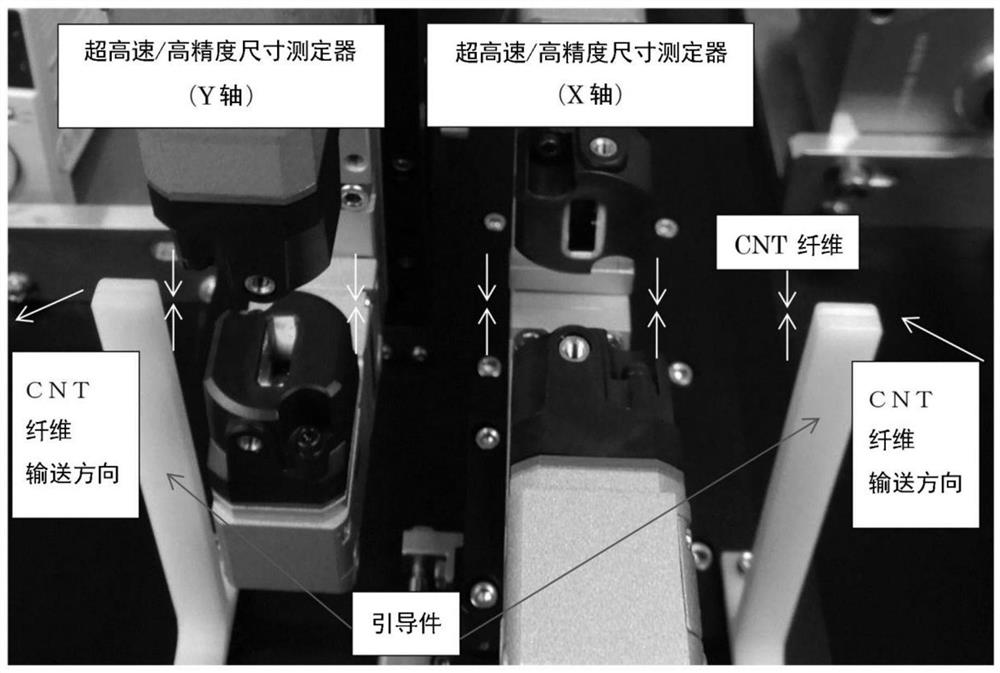

Method used

Image

Examples

Embodiment 1

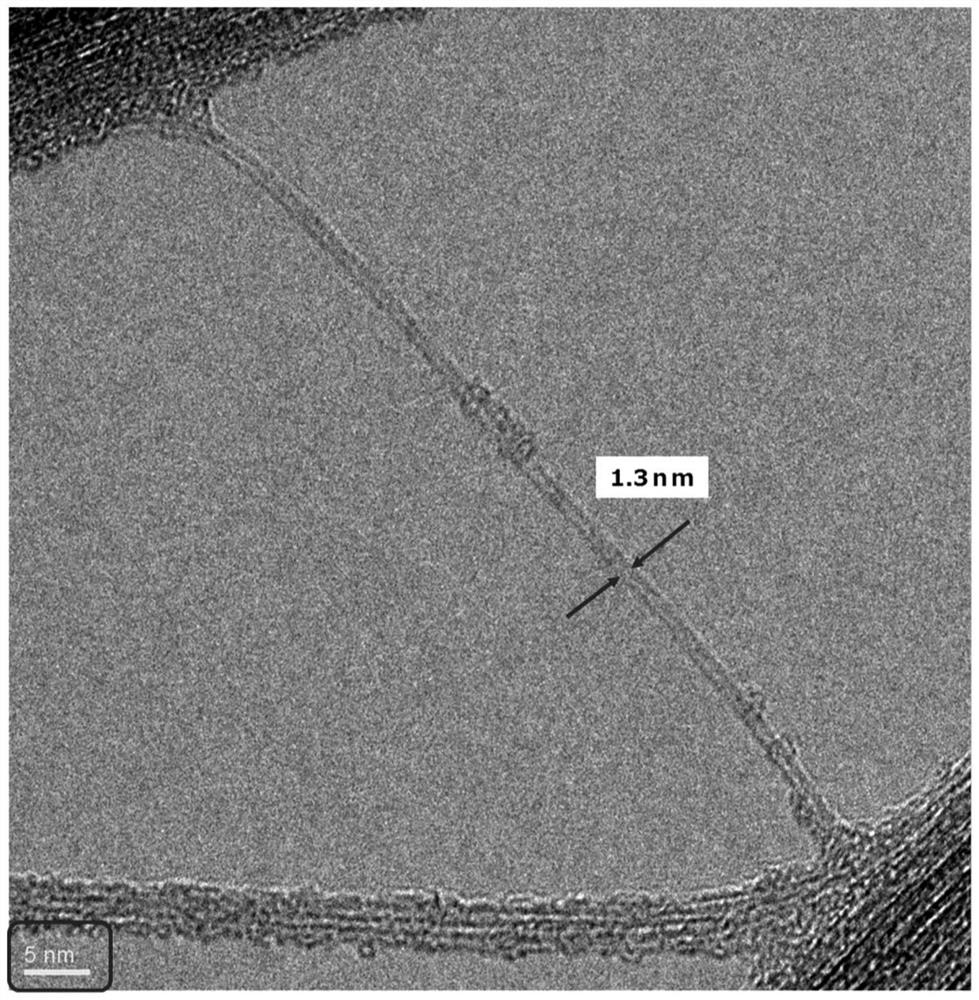

[0105] To 1988 g of water, 4 g of CNT (manufactured by MEIJO NANOCARBON CO., LTD., EC1.4, also referred to as eDIPS-CNT hereinafter) produced by the enhanced direct injection pyrolysis synthesis method (eDIPS method) and taurodeoxycholic acid were added 8 g of sodium (manufactured by Sigma-Aldrich LLC., also referred to as TDOC.) was dispersed for 60 minutes using an ultra-high-speed multi-function stirring system (manufactured by Primix Inc., LABOLUTION). Then, the defoaming operation was performed for 10 minutes using an autorotation revolution mixer (Awatori Rentaro ARE-250, manufactured by Thinky Corporation) to obtain an eDIPS-CNT dispersion having an eDIPS-CNT weight concentration of 0.2 mass %.

[0106] Heat was applied to the obtained eDIPS-CNT dispersion liquid on a hot plate to evaporate water so that the weight concentration of eDIPS-CNT became 0.4 mass %.

[0107] After filling the eDIPS-CNT dispersion in a syringe, an injection spinning nozzle with an inner diamet...

Embodiment 2

[0112] The same procedure as in Example 1 was carried out, except that the water in the eDIPS-CNT dispersion of Example 1 was further evaporated, and the eDIPS-CNT dispersion whose weight concentration of eDips-CNT was adjusted to be 0.6 mass % was used to obtain CNT fibers. The obtained CNT fibers were as follows: average diameter: 30 μm, coefficient of variation: 0.10, distribution ratio a: 52%, distribution ratio b: 80%, presence ratio of CNTs with a diameter of 5 nm or less: 95%, G / D ratio: 28, Electrical conductivity: 5600S / cm, fiber density: 0.6g / cm 3 .

Embodiment 3

[0114] A CNT fiber was obtained in the same manner as in Example 1, except that an injection spinning nozzle with an inner diameter of 0.41 mm was used in place of the injection spinning nozzle with an inner diameter of 0.21 mm. The obtained CNT fibers were as follows: average diameter: 53 μm, coefficient of variation: 0.15, distribution ratio a: 49%, distribution ratio b: 75%, presence ratio of CNTs with a diameter of 5 nm or less: 96%, G / D ratio: 25, Electrical conductivity 4000S / cm, fiber density: 0.5g / cm 3 . In addition, the evaluation of the compactness of the coil was performed, and the compactness of the coil (area ratio of CNT fibers) was 85%, which was a value higher than that of Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com