A coil winding device and method of winding an elongate member

A long, component technology, applied in the field of coil winding devices, to achieve the effects of minimizing the amount of work hardening, minimizing the three-dimensional space, and reducing the free space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

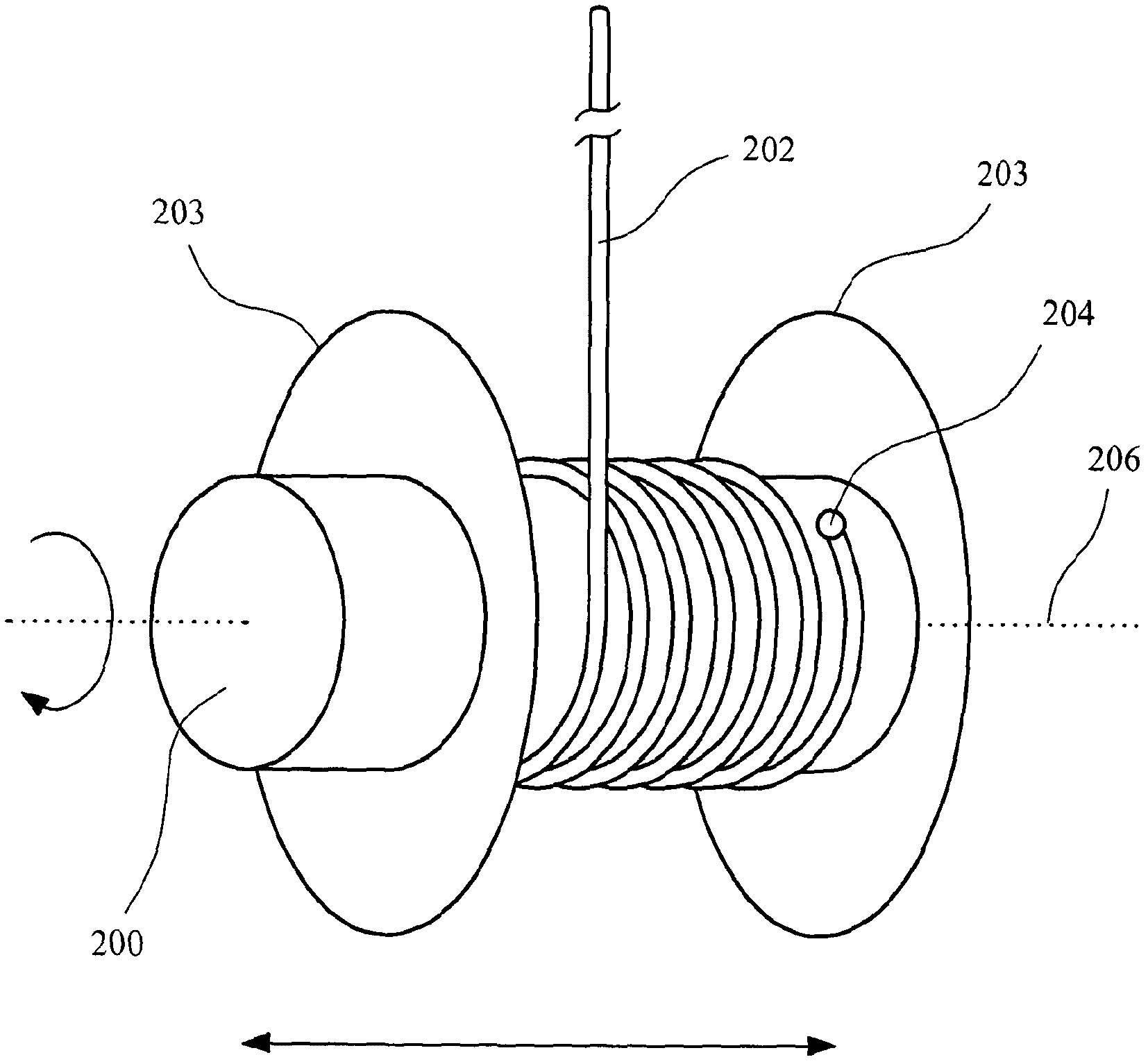

[0049] refer to Figure 4A , 4B and 4C, a winding device 300 is provided for winding an elongate member, such as a metal tube 303, into a coil. The winding device 300 has a first body portion 302 and a second body portion 304 each preferably disc-shaped. The first body portion 302 is adapted to rotate about a first axis 306 . The winding device 300 has fixing means for fixing a part of the tube 303 extending from the guide member 305 to the first body part 302 . The metal pipe passes through the guide member 305 and utilizes Figure 7 The automatic clamping system shown is connected to a purging unit in the first body portion 302 . The second body portion 304 has a plurality of hairs 308 extending from the second body portion 304 in the direction of the first body portion 302 and a cylindrically shaped member 309 . Preferably, the length of the hairs 308 and shaping member 309 is about twice the diameter of the tube 303 to be wound into a coil by the device 300 . The shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com