Electrode group structure of winding type accumulator

A technology for electrode groups and storage batteries, which is applied in the manufacture of battery electrodes, structural parts, and secondary batteries. It can solve the problems of prismatic shape, poor electrode winding performance, and lower battery assembly yield, so as to reduce short-circuit or micro-short hazards. , It is not easy to break, and the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

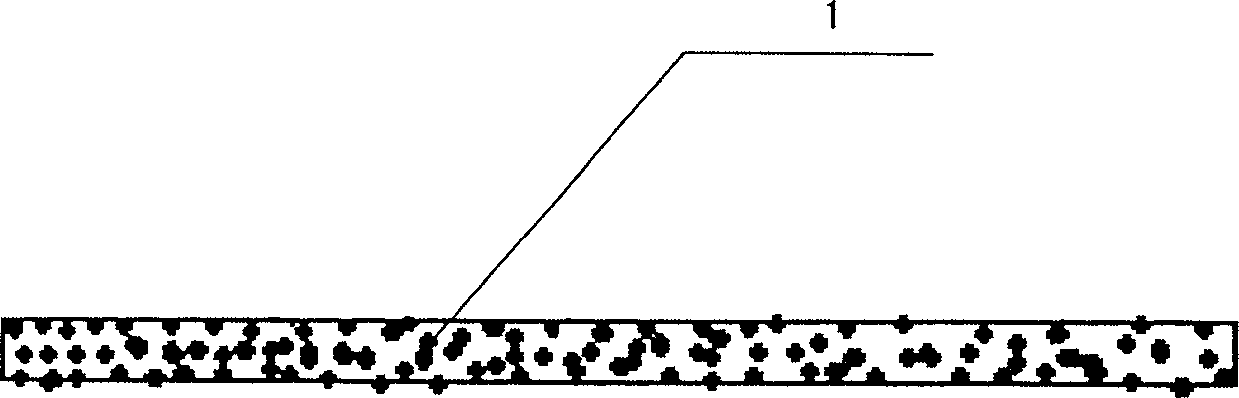

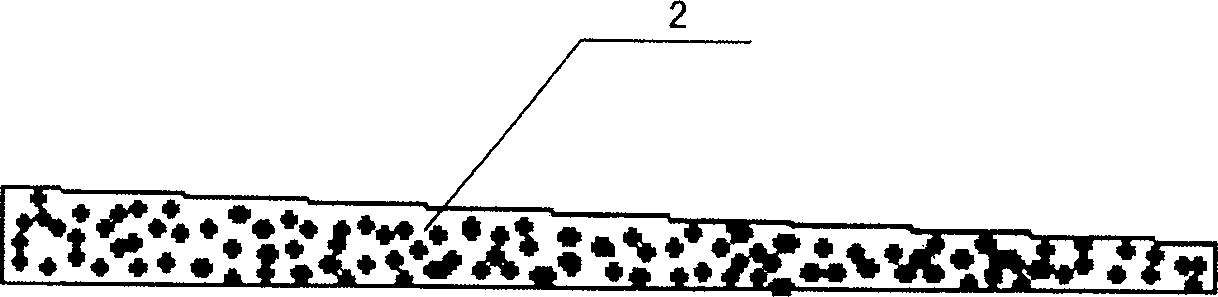

[0012] Referring to the accompanying drawings, an electrode group structure of a winding battery is composed of a positive electrode 1, a negative electrode 2 and a separator between the two electrodes. The density or thickness of the electrode group is different in the winding direction. The electrode group roll The density of the core portion is low or the thickness is thin.

[0013] In the electrode group, the density or thickness of the positive electrode 1 in the winding direction may be different, and the density or thickness of the winding core of the positive electrode 1 is low; it may also be that the density or thickness of the negative electrode 2 in the winding direction is different, and the negative electrode 2 The density of the winding core is low or the thickness is thin; or the density of the positive electrode 1 and the negative electrode 2 is low or the thickness of the winding core is low.

[0014] In the present invention, the density of the electrode gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com