Automatic control filter bag folding machine

A folding machine and filter bag technology, applied in the direction of winding strips, thin material processing, transportation and packaging, can solve the problems of the filter bag is not tight enough, the filter bag is easy to loosen, etc., to achieve simple structure, improve work efficiency, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

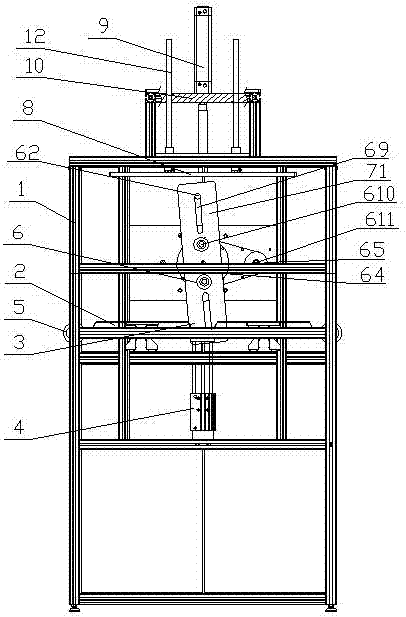

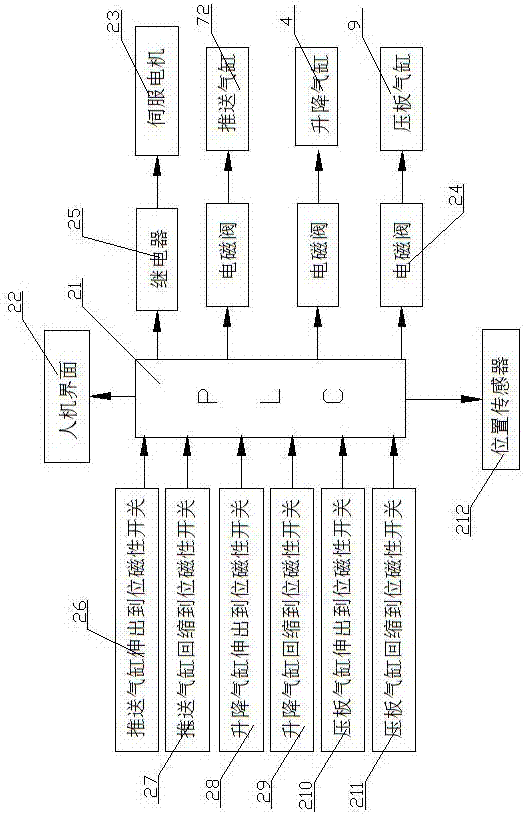

[0026] Such as figure 1 , 2 , 3, the present invention includes a frame 1, the frame 1 is provided with a liftable floating plate 2 for placing filter bags to be folded, the middle part of the floating plate 2 is provided with a gap 3, and the bottom of the floating plate 2 is provided with There is a lifting cylinder 4 installed on the frame 1, the output end of the lifting cylinder 4 is connected with the floating plate 2, and is used to drive the floating plate 2 to move up and down. roll 5.

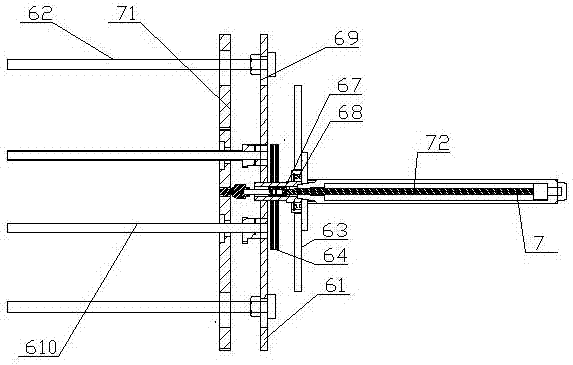

[0027] The winding mechanism 6 includes a rotating plate 61 arranged above the middle part of the floating plate 2, the two ends of the rotating plate 61 are equipped with a winding shaft 62 arranged forward, and the rear of the rotating plate 61 is provided with a mounting plate connected to the frame 1 63, the mounting plate 63 is equipped with a driving mechanism that drives the rotating plate 61 to rotate. The driving device includes a large pulley 64, a small pulley 65 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com