Method for fixing end of metal foil and steel sleeve

A fixing method and metal foil technology are applied in the field of fixing the end and the steel sleeve during the rolling of metal foil, which can solve the problems of inability to carry out rolling, easy to be discounted, and the thickness of the foil is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

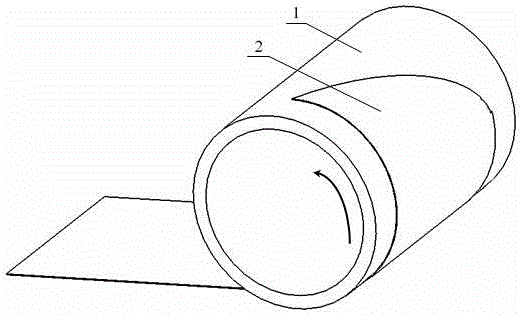

[0014] Such as figure 1 As shown, in the fixing method of the present invention, the thickness of the metal foil should be less than or equal to 20 microns, and when fixed between the winding sleeve 1 and the metal foil 2,

[0015] In the first step, a layer of rolling oil is attached to the inner surface of the metal foil 2 and the winding sleeve 1;

[0016] In the second step, the flat end of the metal foil material 2 is cut into a 30°~60° oblique shape;

[0017] In the third step, the metal foil material 2 is directly attached to the outer surface of the winding sleeve 1 by using the rolling oil attached to the surface of the metal foil material 2 .

[0018] The fourth step is to turn on the winding machine and drive the winding sleeve 1 to rotate 3 to 5 times along the winding direction of the metal foil material 2. At this time, the metal foil material 2 does not rotate with the winding sleeve 1;

[0019] In the fifth step, during the independent rotation of the winding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com