Metal gauze for rewinding screen window

A metal gauze, screen window technology, applied in the direction of blinds/moving grilles, insect repellents, etc., can solve the problems of difficult winding, easy damage, tilting, etc., and achieve the effect of winding smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

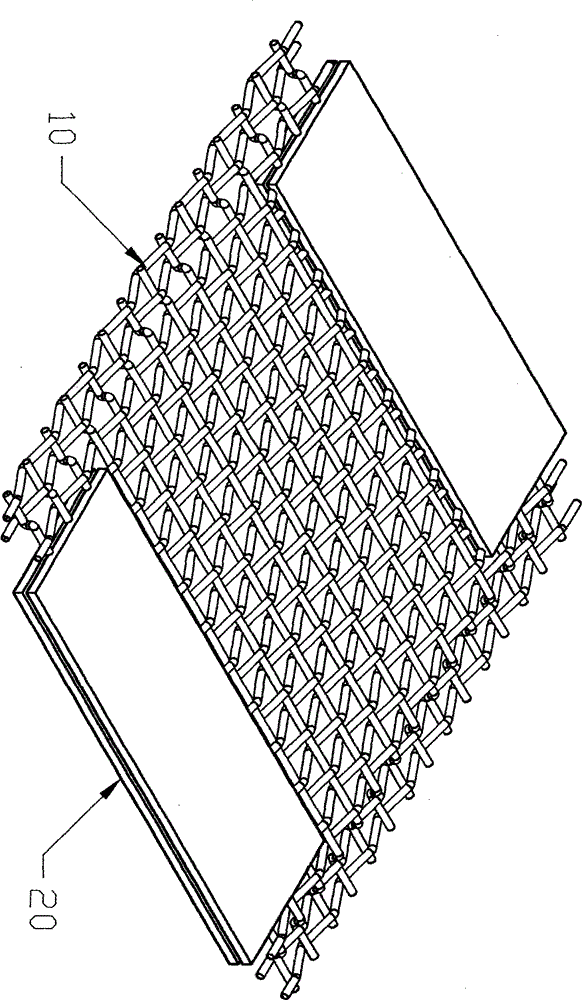

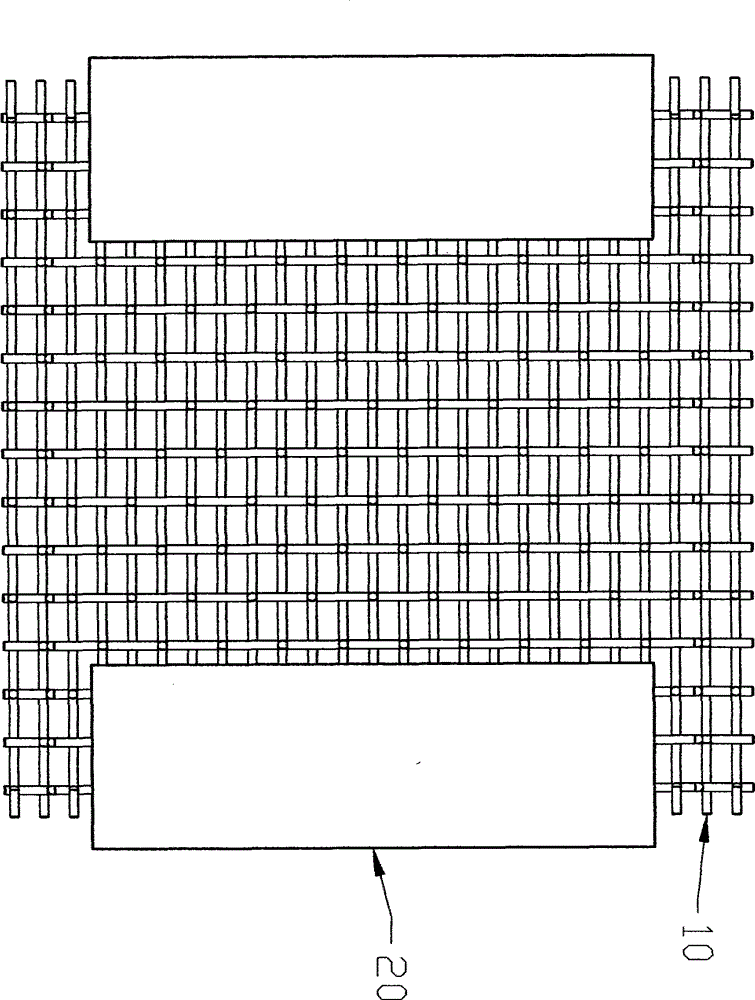

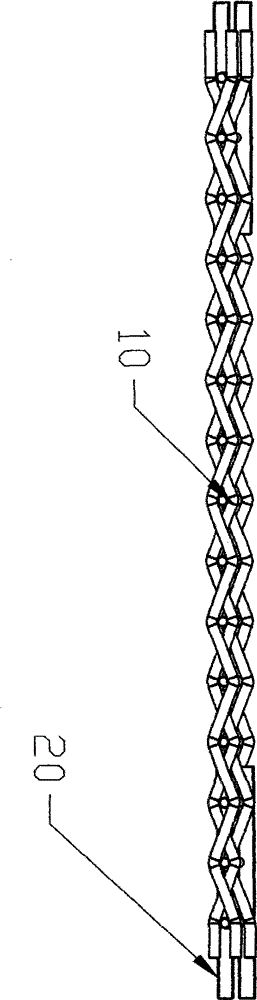

[0018] A metal gauze for rewinding window screens, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it consists of metal gauze 10 and plastic edge 20. The metal gauze 10 is an existing stainless steel mesh, titanium steel mesh, aluminum wire mesh and anti-rust treated wire mesh made of warp and weft threads. The section of the plastic side 20 is as Figure 5 As shown, it is made up of two thin sheet plastic edges 21,22 up and down. The edges on both sides of the metal gauze 10 are connected to the plastic edge 20, and the plastic edge 20 is embedded into the hole of the metal gauze 10 and covers the edge of the metal gauze 10 through machine heating and pressure. There is a concave fold 11 on the other two sides of the metal gauze 10 about 10 centimeters away from the edge, and the plastic edge 20 on both sides of the metal gauze 10 forms a rectangle with the concave fold 11 on the other two sides.

Embodiment 2

[0020] The plastic side section can also be as Figure 6 As shown, it consists of upper and lower two sheet plastic sides 31, 32, one of which is a short rectangle in section, and the other section is a long rectangle that can be bent into a folded edge 33.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com