Cable take-up reel eccentric winding current collecting device

A technology of collecting device and cable reel, which is applied in the direction of using take-up reel/photosensitive drum arrangement, etc., can solve the problems of internal optical cable or cable damage, increased friction between cables, and increased volume, etc. Increased service life, reduced friction, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

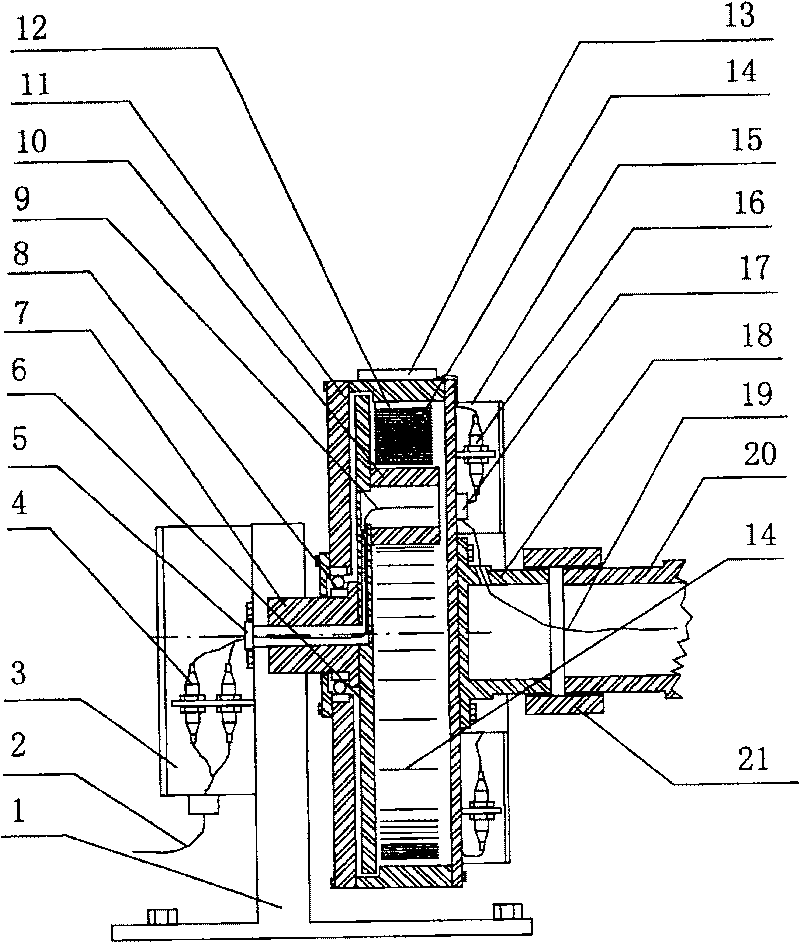

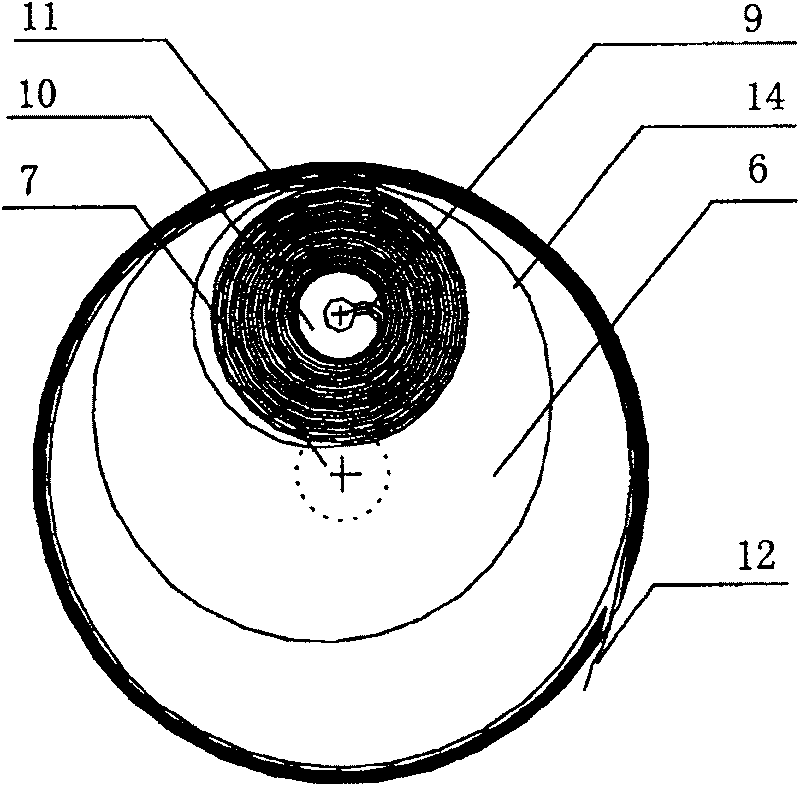

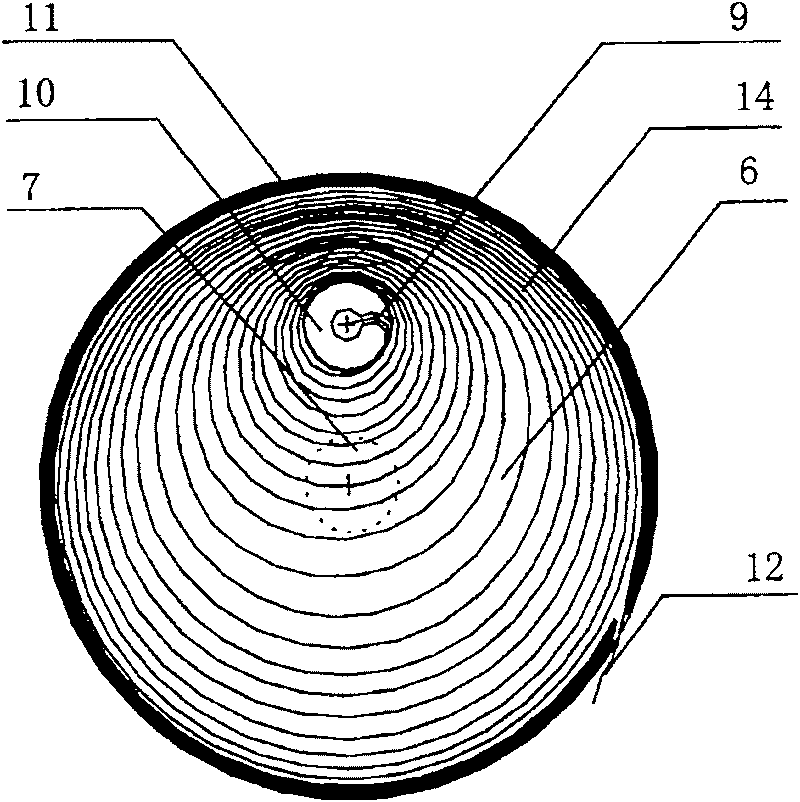

[0019] see figure 1 , an eccentric winding current collector for a cable reel, comprising a fixed part and a rotating part. The fixed part includes a base 1, a central shaft 7, a rear base plate 6, and an eccentric shaft 10. The base 1 is fixed with an inner hollow central shaft 7, and the central shaft 7 is equipped with a rear base plate 6, and the rear base plate 6 is processed with a center shaft 7. The threading hole that hollow hole communicates, the top of back base plate 6 is fixedly equipped with inner hollow eccentric shaft 10, and the shaft wall of eccentric shaft 10 has a threading groove that communicates with eccentric shaft inner hollow hole. The junction box 3 of the fixed part is also installed on the base 1, and a fiber optic cable splitter 5 is housed in the junction box 3, and an optical fiber connector 4 using an equal number of fiber cores of the fiber optic cable. The rear portion of the fixed portion junction box 3 has a threading hole. The threading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com