Wire drawing machine

A wire drawing machine and wire drawing technology, applied in the field of wire drawing machines, can solve problems such as easy slipping and loose winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

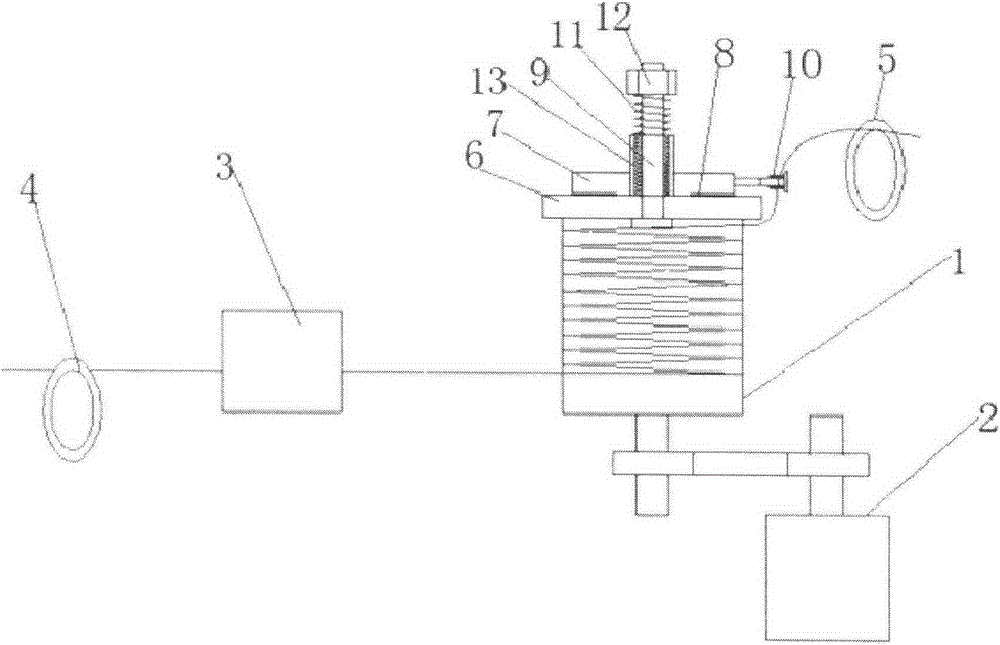

[0012] refer to figure 1 A wire drawing machine is shown, which includes a reel 1, a reel drive mechanism 2, a wire drawing die box 3, a guide wheel 4, a reel friction disc mechanism and a lead-out wheel 5, and the reel friction disc mechanism is arranged on the reel On the cylinder cover 6, the reel friction disc mechanism includes a friction disc 7, a friction plate 8, a friction disc shaft 9, a wire puller assembly 10 and a compression spring 11, and the compression spring 11 is arranged above the friction disc 7 and on the friction disc On the shaft 9, an adjustment nut block 12 is arranged on the top of the compression spring 11, and the adjustment nut block 12 is threadedly matched with the top end of the friction disc shaft 9. Rubber sleeves 13 are arranged between the discs 7, the thread puller parts 10 are connected to the friction discs 7, and the lead-out wheel 5 is arranged obliquely above the thread puller.

[0013] In order to protect the motor and prevent the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com