Automatic mask feeding device and folding mask machine with the device

An automatic feeding and mask technology, applied in the field of mask machines, can solve the problems of easy wrinkling of raw materials, unfavorable feeding efficiency, lack of raw material tension, etc., to achieve the effect of easy disassembly and installation, good driving effect, and avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

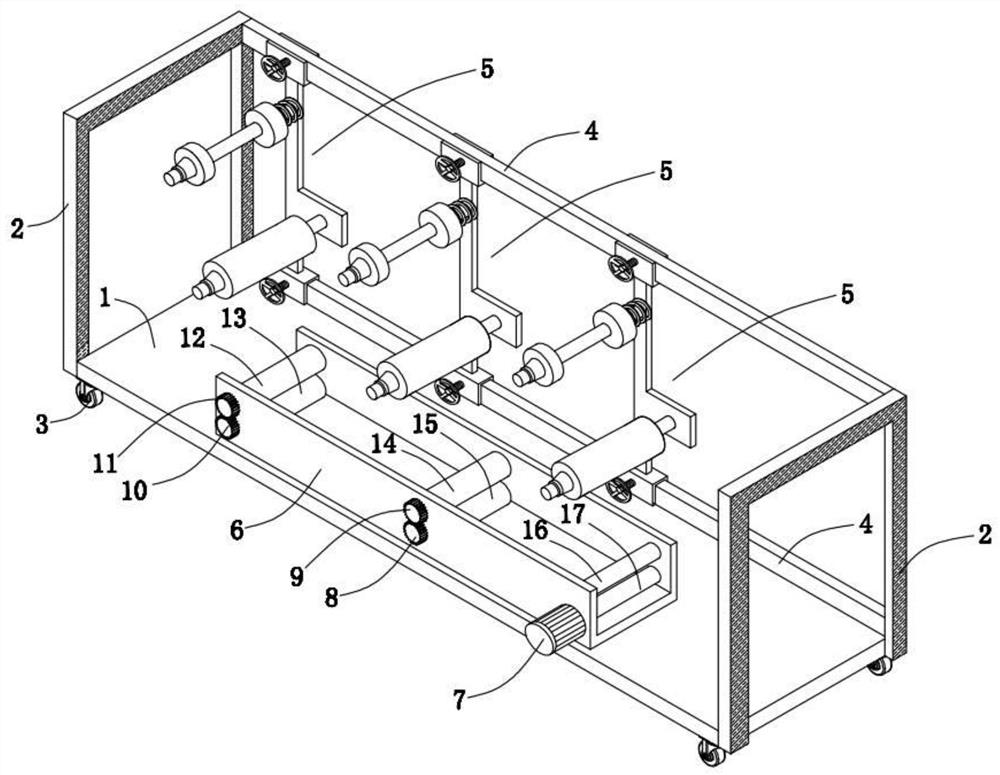

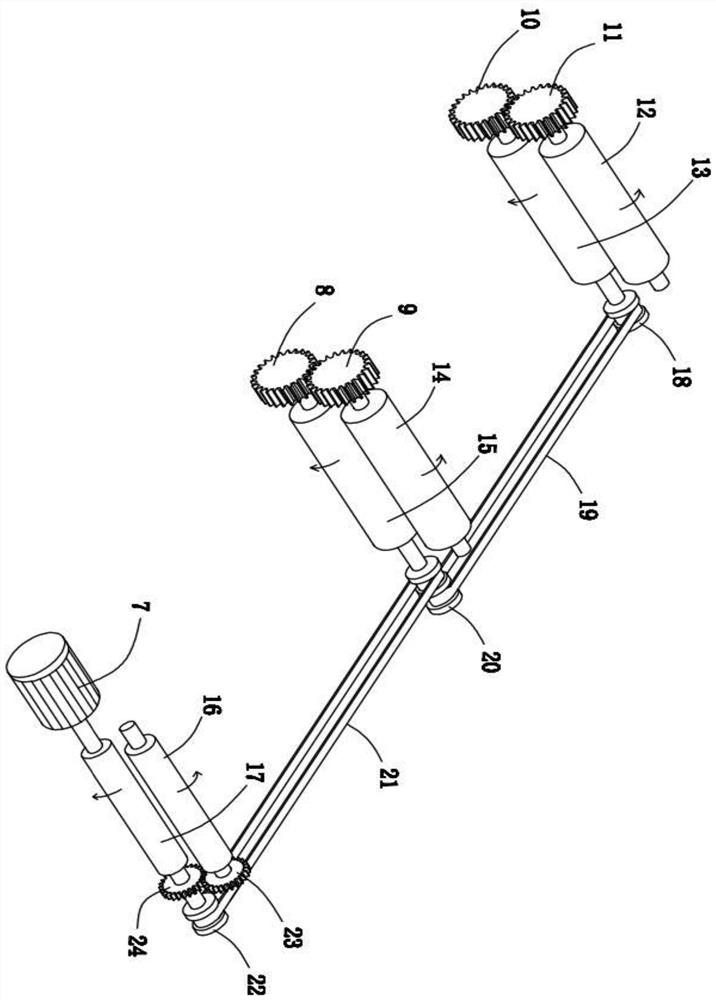

[0024] like Figure 1-4 As shown, a mask automatic upper device, including:

[0025] The base 1 of the moving wheel 3 is mounted at the bottom, and the side holder 2 is connected to both sides thereof, and the side bracket 2 is connected between the two sets of parallel rails 4, between the two sets of rails 4 Sliding has a number of groups of flush assemblies 5;

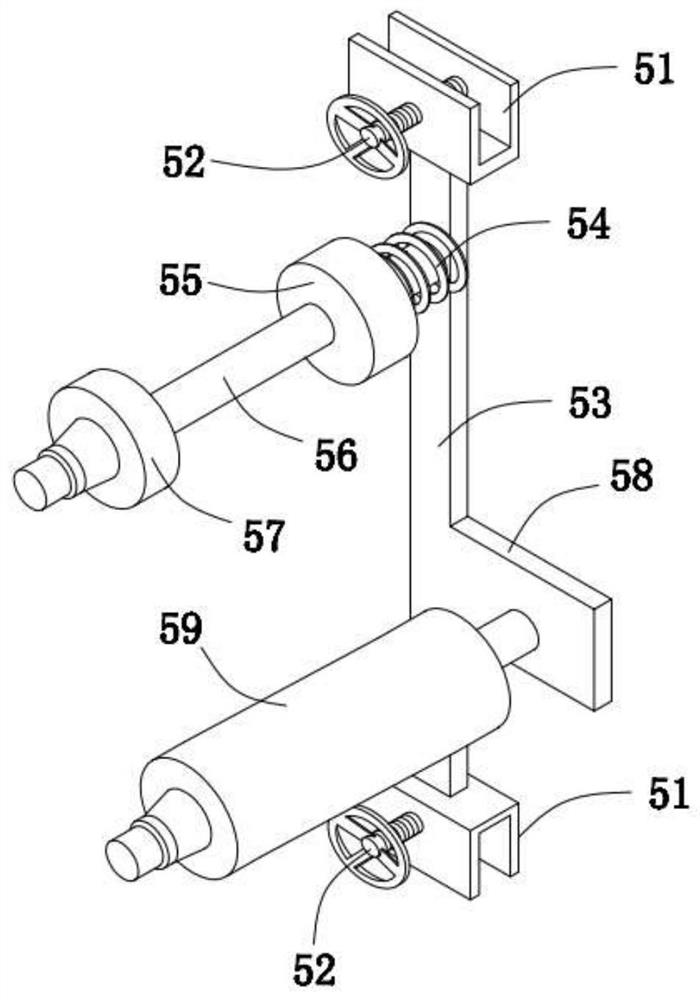

[0026] The mount assembly 5 includes a mount lever 56 and a tension roller 59, the mount rod 56, which is lined with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com