Efficient flange mold structure for flange rapid forming and casting method

A flange and fast technology, applied in casting equipment, casting molding equipment, casting molds, etc., can solve the problems of low molding efficiency, inability to adjust processing efficiency and output, and inability to adjust condensation molding efficiency, etc., to achieve the effect of flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

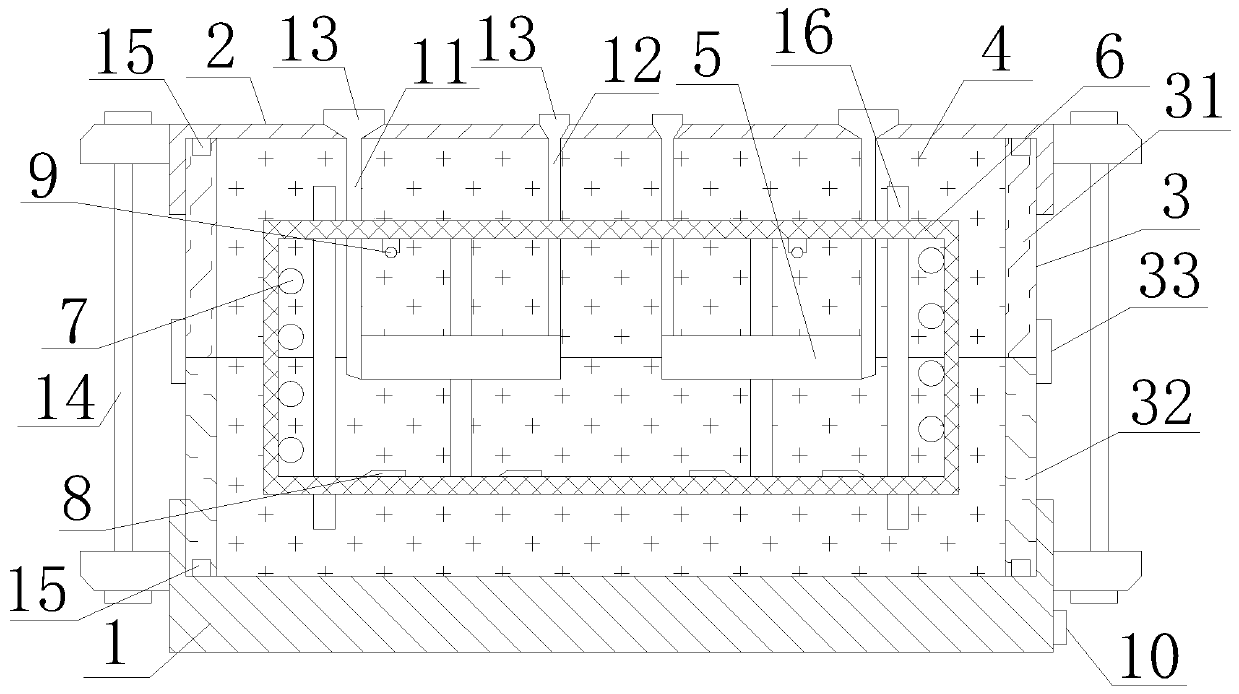

[0020] Such as figure 1 As shown, a high-efficiency flange mold structure for rapid prototyping of flanges includes a bearing base 1, a sealing end cover 2, a molding box 3, molding sand 4, a molding sand core 5, a bearing keel 6, a heat exchange tube 7, and an electromagnet 8 , the temperature sensor 9 and the drive circuit 10, the carrying base 1 and the sealing cover 2 both have a cross-section in the shape of a "凵"-shaped groove structure, the carrying base 1 and the sealing end cover 2 are connected by a forming box 3, and the forming box 3 It is a rectangular closed frame structure coaxially distributed with the bearing base 1 and the sealing end cover 2, and forms a closed cavity structure together with the bearing base 1 and the sealing end cover 2. The bearing keel 6 is embedded in the forming box 3, and is A frame structure coaxially distributed with the forming box 3, 2-8 forming sand cores 5 in total, embedded in the forming box 3 through the bearing keel 6, and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com