Warp-knitted fabric continuous rolling and outputting equipment

A technology for outputting equipment and fabrics, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of loose winding and low efficiency, and achieve the goal of improving efficiency, ensuring continuity and ensuring high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

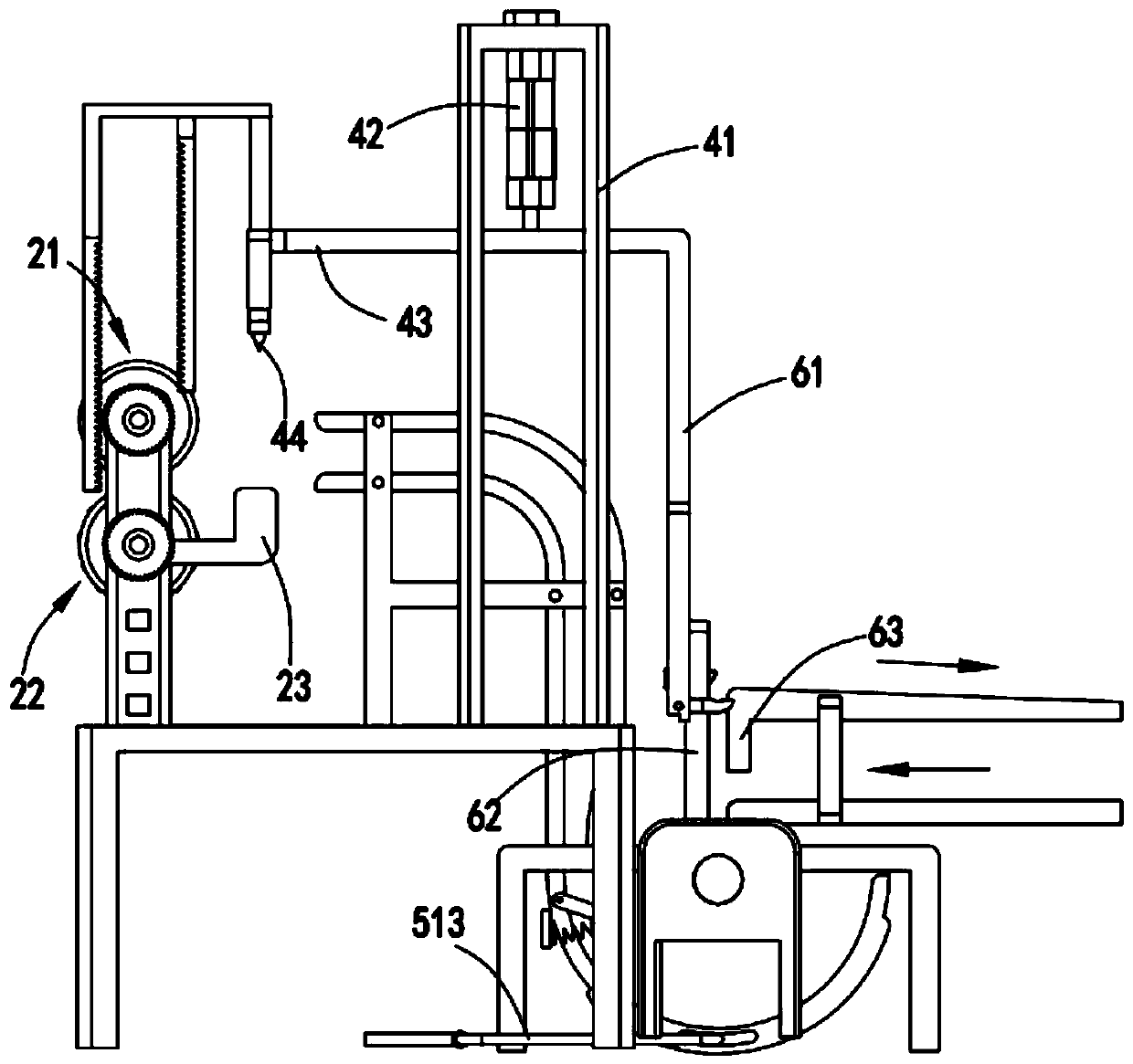

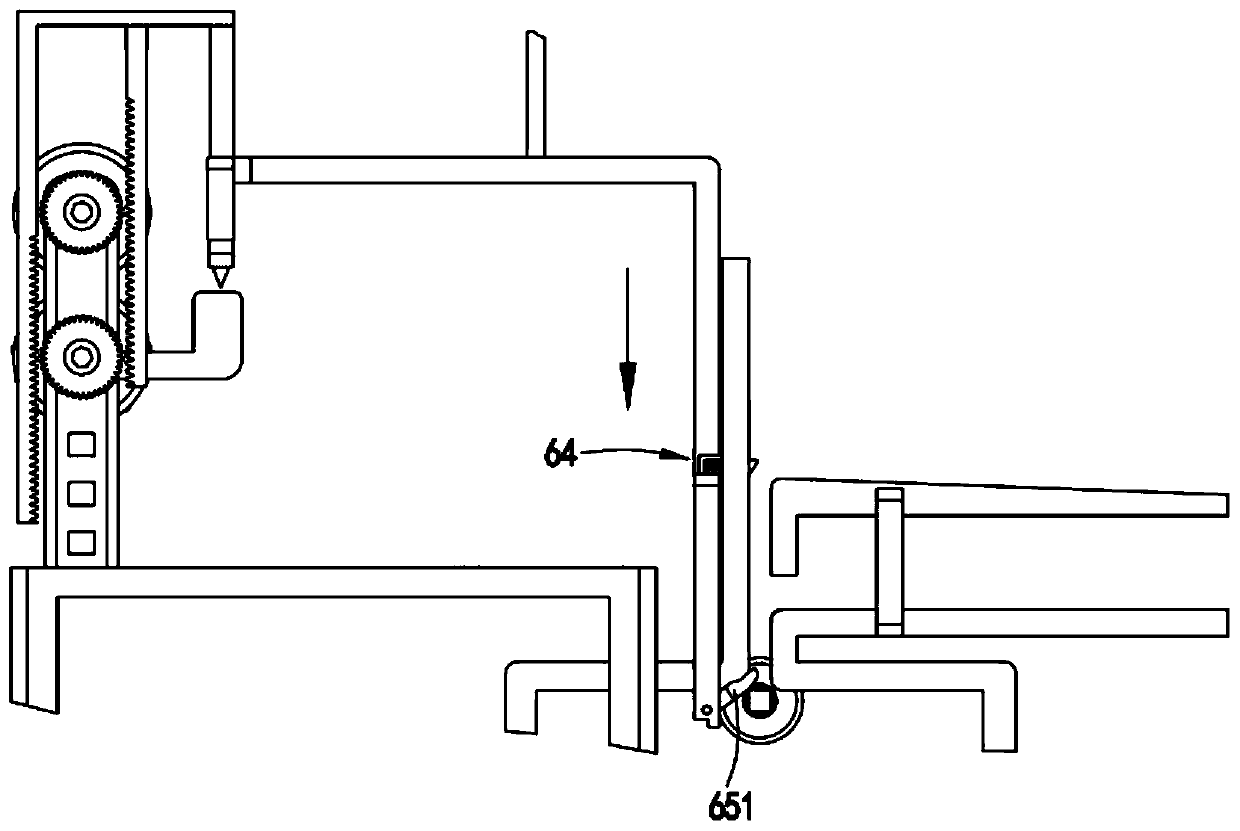

[0046] Such as Figure 1 to Figure 15 As shown, a warp knitted fabric continuous winding output device includes a base 1, on which a delivery mechanism 2 and a guide mechanism 3 are sequentially arranged from front to back, and the delivery mechanism 2 and the guide mechanism 3 are arranged between There is a cutting mechanism 4, the tail end of the guide mechanism 3 is provided with a winding mechanism 5, and the top of the winding mechanism 5 is provided with an output mechanism 6 for entering and exiting the cloth roller 10;

[0047] The cloth roller 10 is driven by the winding mechanism 5 to complete the cloth winding. After the winding is completed, the delivery mechanism 2 cooperates with the cutting mechanism 4 to cut the cloth. After the cutting is completed, the cutting mechanism 4 resets and starts During the reset process, the delivery mechanism 2 drives the end of the cloth to be rolled up along the guide mechanism 3 to the winding mechanism 5. At the same time, th...

Embodiment 2

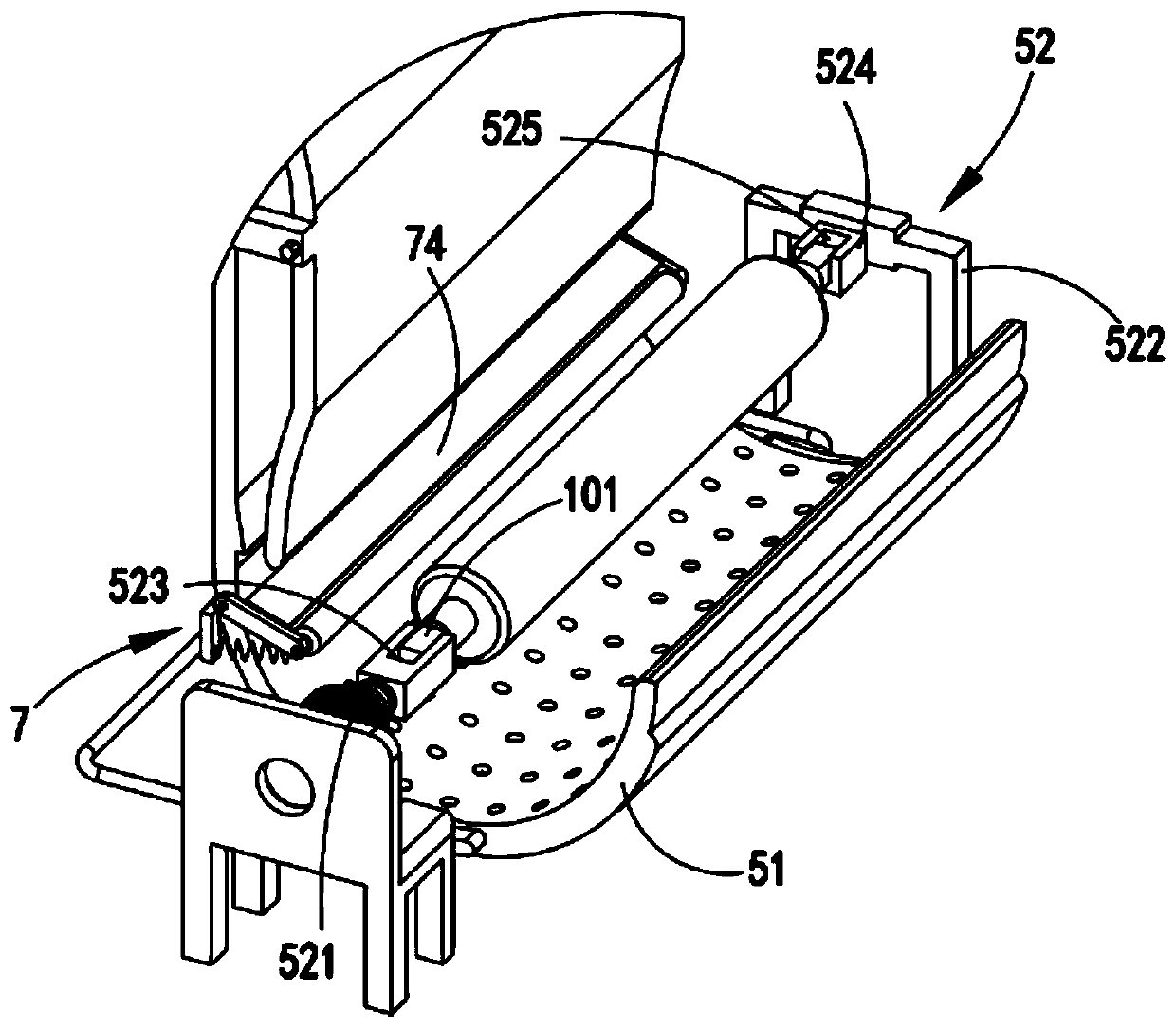

[0064] Such as image 3 , Figure 6 and Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, a winding auxiliary assembly 7 is provided at the tail end of the lower guide plate 33, and the winding auxiliary assembly 7 includes a rotatable set on the lower guide The turret b71 on the plate 33, the end of the turret b71 is rotatably provided with a pressure roller 72, a spring 73 is connected between the turret b71 and the lower guide plate 33, and one side of the pressure roller 72 is also A guide plate 74 fixed to the turret b71 is provided.

[0065] In this embodiment, the cloth is guided along the guide channel 34 by setting the winding auxiliary assembly 7 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com