Textile warp knitting production equipment and textile warp knitting production method

A kind of production equipment and warp knitting technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of time-consuming and laborious fabric winding, waste of winding space, and low winding efficiency, so as to achieve improved effect and good effect , the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

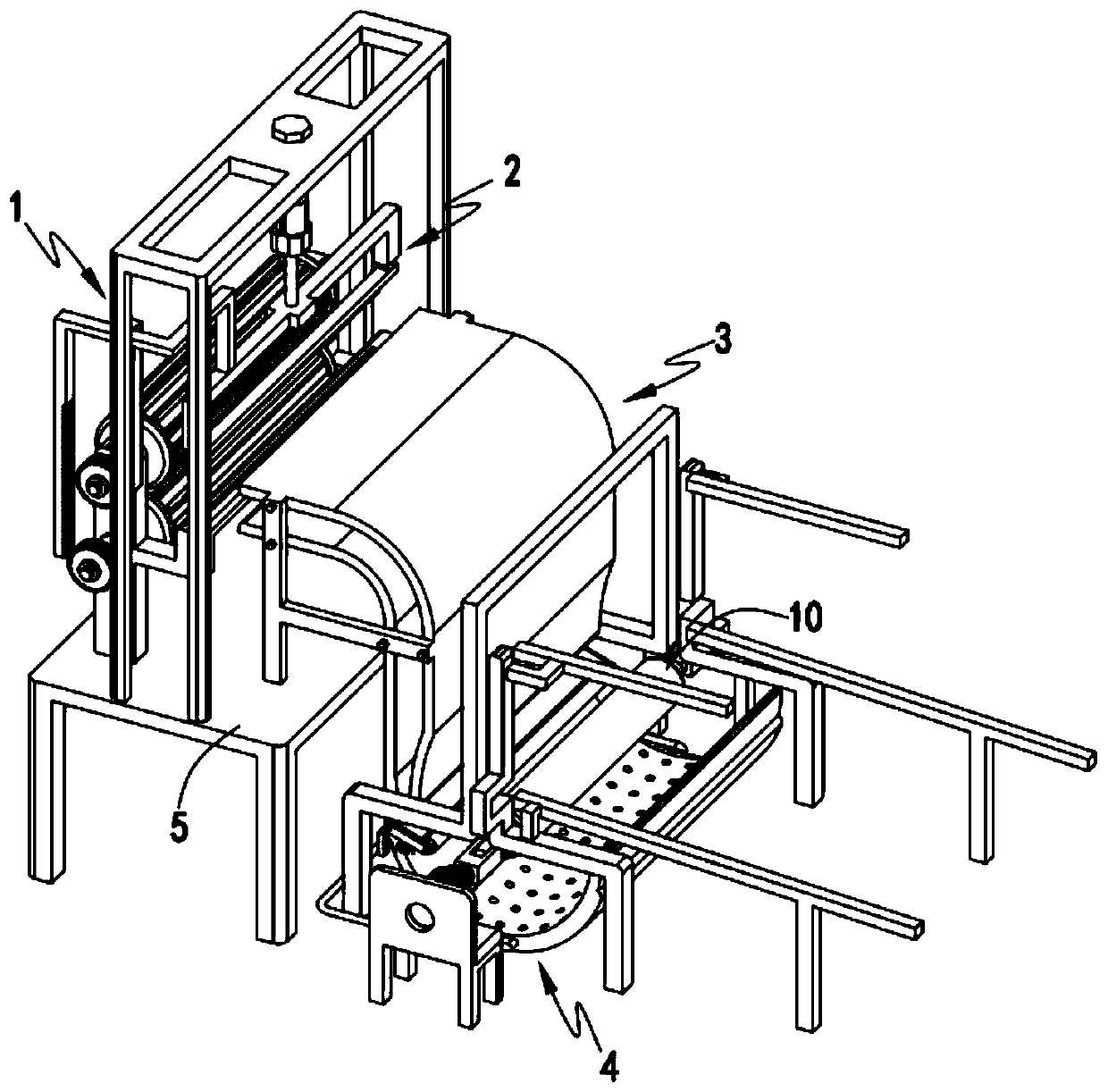

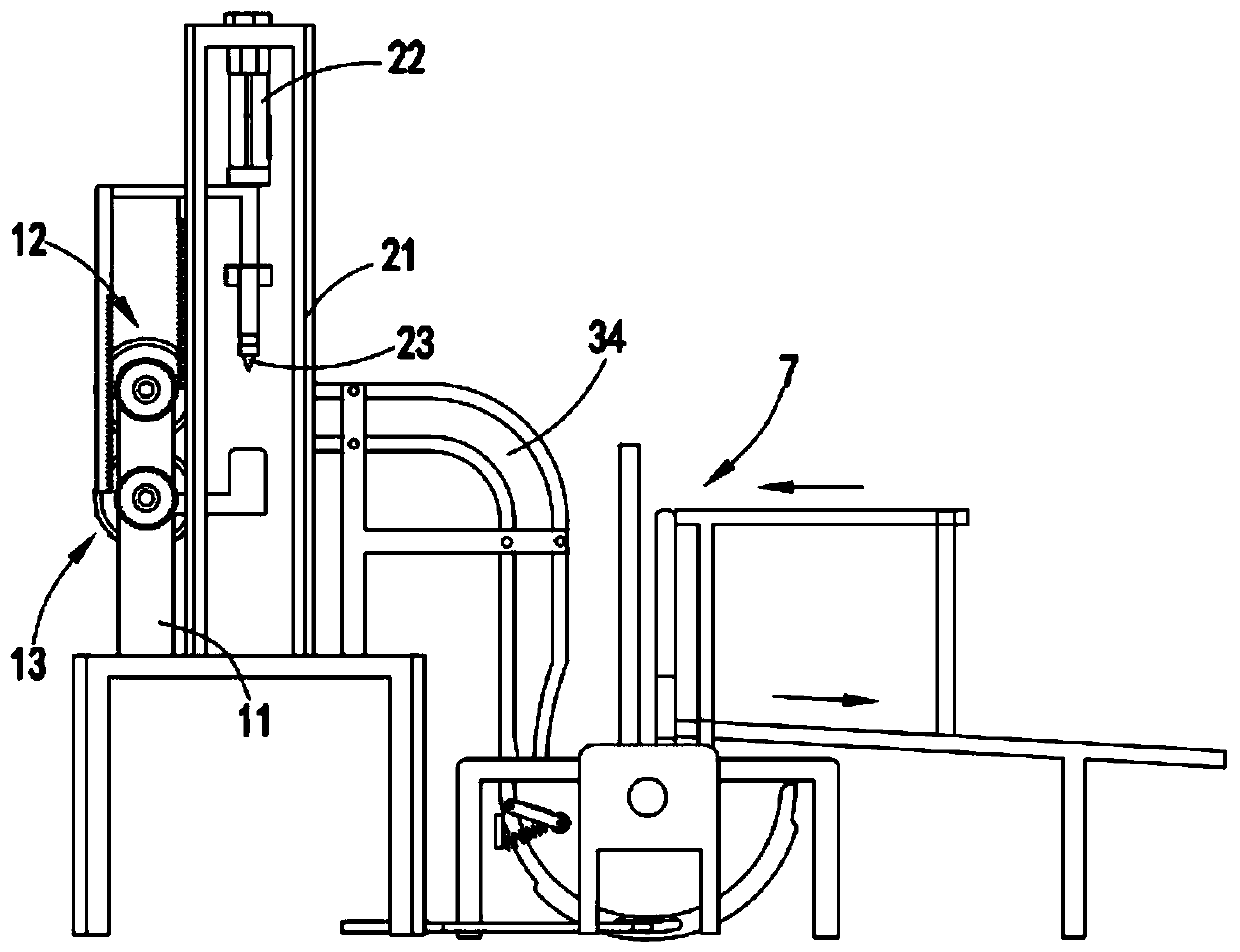

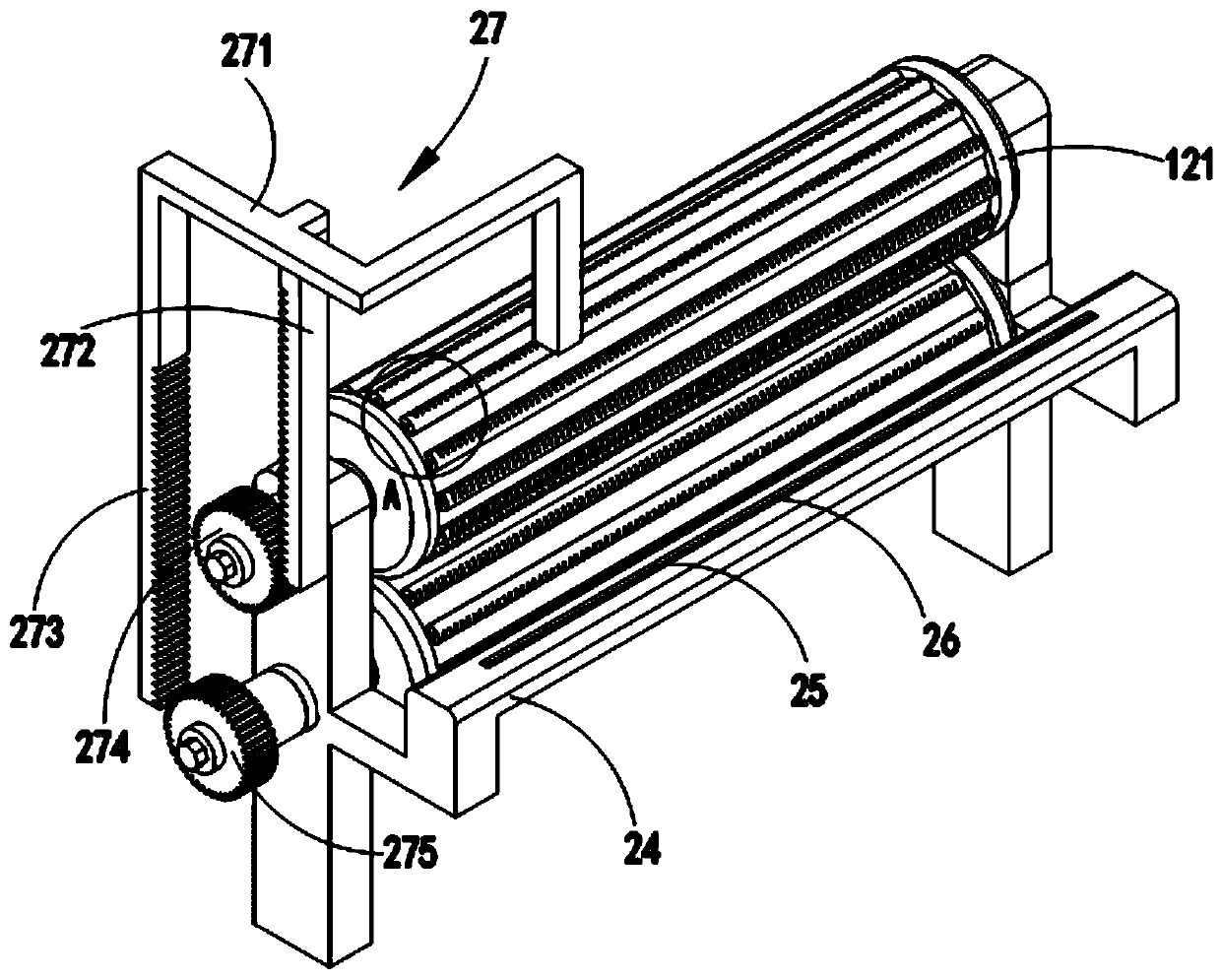

[0052] Such as Figure 1 to Figure 11 Shown, a kind of textile warp knitting production equipment comprises base 5, winding roller 10, is characterized in that, also comprises cloth delivery mechanism 1, the cutting mechanism 2 that is arranged on the cloth delivery mechanism 1 back, is arranged on the cutting mechanism 2 the guiding mechanism 3 at the rear and the winding mechanism 4 arranged at the tail end of the guiding mechanism 3;

[0053] After the winding roller 10 at the winding mechanism 4 completes winding, the cloth delivery mechanism 1 cooperates with the cutting mechanism 2 to cut the cloth, and after the cutting is completed, the cutting mechanism 2 resets and during the reset process The unrolled cloth driven by the cloth delivery mechanism 1 is sent to the winding mechanism 4 along the guide mechanism 3, and the winding mechanism 4 cooperates with the next winding roller 10 to continue winding the cloth.

[0054] Further, the cloth delivery mechanism 1 includ...

Embodiment 2

[0067] Such as Figure 5 and Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is: further, a winding auxiliary assembly 6 is provided at the tail end of the lower guide plate 33, and the winding auxiliary assembly 6 includes a 33 on the turret b61, the end of the turret b61 is rotatably provided with a pressure roller 62, a spring 63 is connected between the turret b61 and the lower guide plate 33, and one side of the pressure roller 62 is also set There is a guide plate 64 fixed on the turret b61.

[0068] In this embodiment, by setting the winding auxiliary assembly, when the cloth is transported to the winding station along the guide passage, it can lean against the surfac...

Embodiment 3

[0070] Such as Figure 12 Shown, a kind of textile warp knitting production method is characterized in that, comprises the following production steps:

[0071] (a), the warp knitting transmission process, the fabric knitted by the warp knitting equipment is transported backward;

[0072] (b), smoothing process, the warp knitted fabric is transmitted through the cloth delivery mechanism 1, and the delivery assembly a12 and the delivery assembly b13 of the cloth delivery mechanism 1 rotate towards the opposite direction of the cloth transmission direction, and the cloth is smoothed;

[0073] (c), winding process, the warp-knitted fabric finished flattening in step b is transmitted to the winding station, and the winding mechanism 4 positioned at the winding station carries out warp-knitted winding to the fabric;

[0074] (d), cutting process, after the winding mechanism 4 finishes winding in the step c, the cutting mechanism (2) at the cutting station cuts off the warp knitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com