High-count and high-density polyester cotton composite yarn fabric and weaving method thereof

A polyester-nylon composite yarn with high count and high density, which is applied in textiles, papermaking, textiles, fabrics, etc. It can solve problems such as pilling and easy fluffing, and achieve the effects of preventing differential shrinkage, reducing damage, and improving sizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

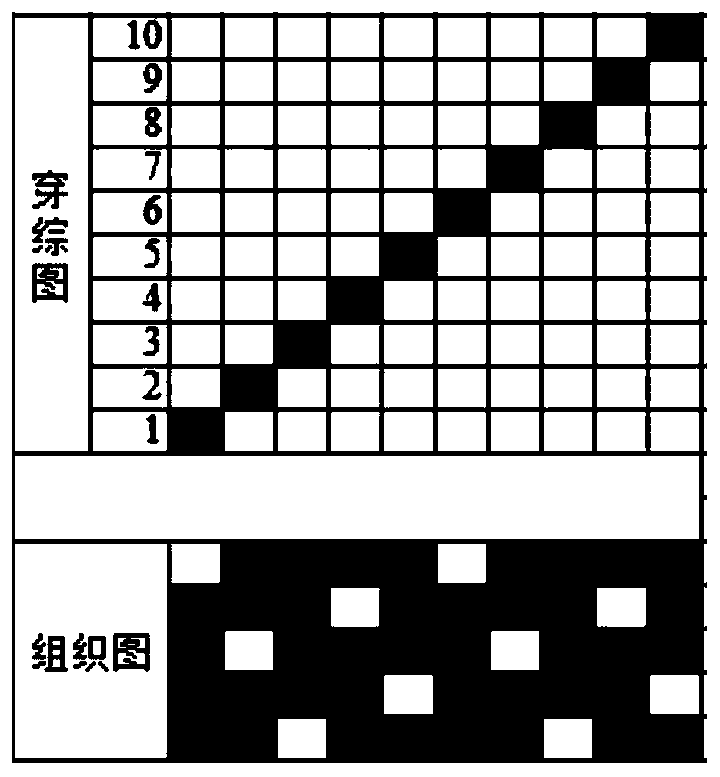

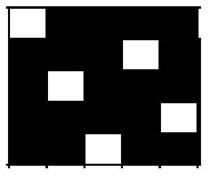

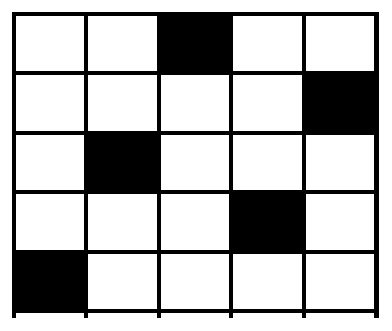

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] This embodiment provides a high-count and high-density polyester-nylon composite silk fabric, which is composed of a front fabric and a back fabric. The warp yarns of the back and back fabrics are all 50D polyester-nylon composite yarns, and the weft yarns are all 80S pure cotton yarns; the weight ratio of nylon in the polyester-nylon composite yarns is 27%, and the pure cotton weft yarns are processed through sizing, and the size is HM when sizing. -328 modified starch, the slurry viscosity is 7mpa.s.

[0031] A weaving technology for high-count and high-density polyester-nylon composite yarn fabrics, comprising the following steps: warping → sizing → paralleling → drafting and reeding → weaving:

[0032] ①Warping: According to the requirement, the warp yarn density of the gray fabric prepared above is 230 yarns / inch, the weft yarn de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com