High-temperature aluminium alloy

A technology for aluminum alloys and casting alloys, applied in the field of cold hardening aluminum casting alloys, which can solve problems such as unfavorable castability and increased tendency of thermal cracking

Active Publication Date: 2008-11-26

АЛЮМИНИУМ РАЙНФЕЛЬДЕН ГМБХ

View PDF11 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Currently AlSi alloys are commonly used as thermally loaded components, the thermal stability is increased by alloying said alloys with Cu (copper), which however increases the tendency to thermal cracking and has a detrimental effect on castability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0060] Further advantages, features and details of the invention can be found from the following description of a preferred exemplary embodiment.

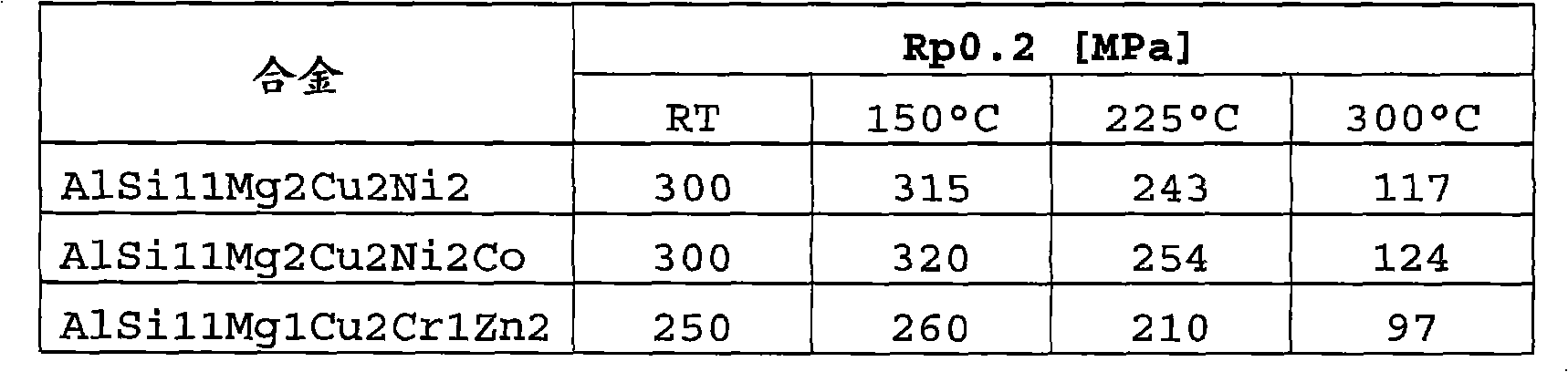

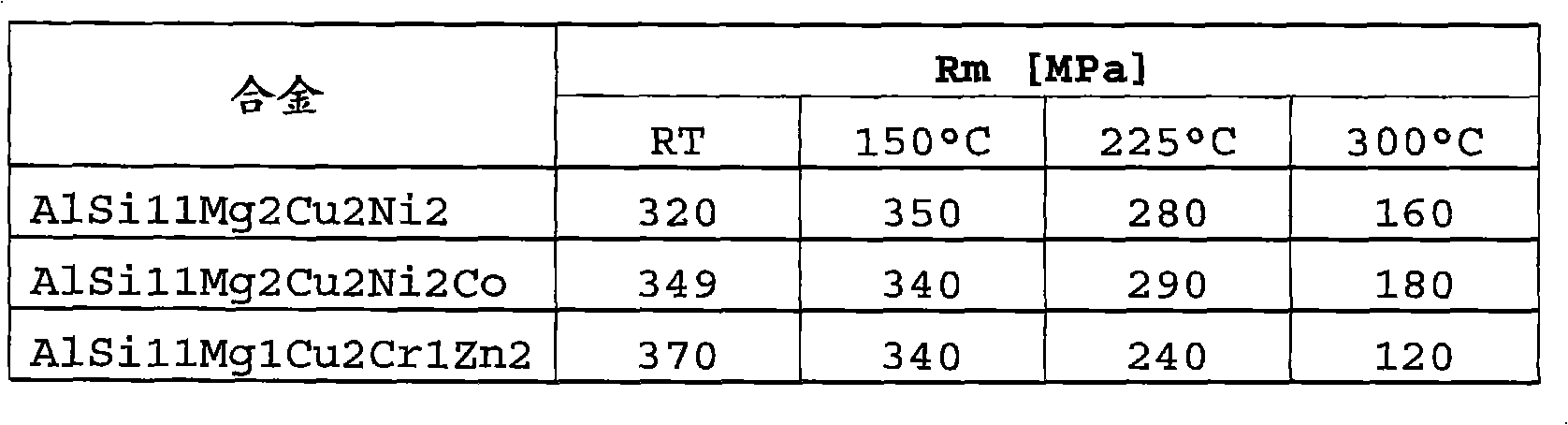

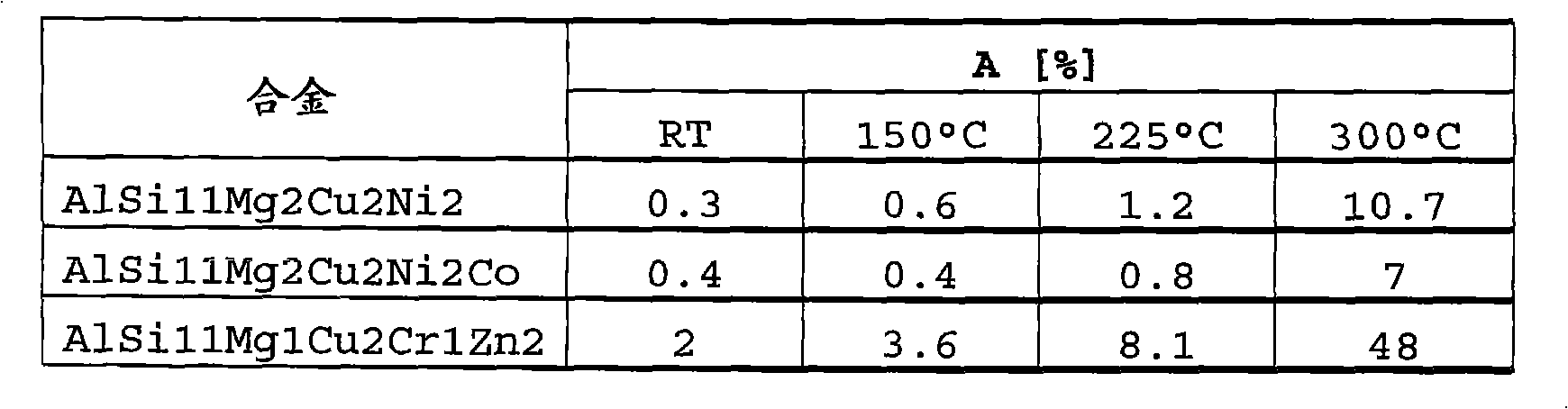

[0061] The alloys according to the invention were cast by die casting to form flat tensile test pieces with a wall thickness of 3 mm. After removal from the die casting mold, the specimens were cooled in still air.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A cold hardening ceralumin used for manufacturing a casting component for bearing heat and mechanical load with excellent thermal stability, comprises: 11.0-12.0 wt% Silicon; 0.7-2.0 wt% Magnesium; 0.1-1 wt% manganese, at most 1 wt% iron; at most 2 wt% copper; at most 2 wt% nickel; at most 1 wt% chromium; at most 1 wt% co; at most 2 wt5 zinc; at most 0.25 wt% Ti; at most 40 ppm boron; optional 80-300 ppm sr and the balance aluminium, and other elements and impurities with respectively at most 0.05 wt% and in total 0.2 wt%. The alloy is particularly suitable to manufacturing a cylinder crankcase through a die manufacturing method.

Description

technical field [0001] The invention relates to work-hardenable aluminum casting alloys having good thermal stability for the manufacture of cast components capable of withstanding thermal and mechanical loads. Background technique [0002] Further developments of diesel engines aimed at improving diesel combustion and obtaining higher specific powers lead, inter alia, to increased explosion pressures and thus to pulsating mechanical loads acting on the cylinder crankcase, which place great demands on the material. Stringent requirements. In addition to high durability, in order to be used in the manufacture of cylinder crankcases, the material must also have high temperature cycle strength. [0003] Currently AlSi alloys are commonly used as thermally loaded components, the thermal stability is increased by alloying said alloys with Cu (copper), which however increases the tendency to thermal cracking and has a negative effect on castability. Applications in which thermal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/02B22D17/00

CPCB22D17/00C22C1/06C22C21/02

Inventor 达恩·德拉古林鲁迪格·弗兰克

Owner АЛЮМИНИУМ РАЙНФЕЛЬДЕН ГМБХ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com