Process for strengthening surfaces of inner and outer walls of non-magnetic drill collar and internal and external threads of joints at two ends

A non-magnetic drill collar, internal and external thread technology, applied in the field of metal surface treatment, can solve the problems of non-magnetic drill collar non-wear resistance stress, corrosion cracking, etc., achieve high hardness, increase wear resistance, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

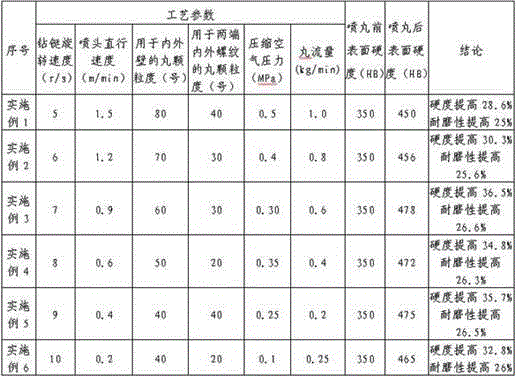

[0016] The present invention is a strengthening process for the inner and outer walls of the non-magnetic drill collar and the inner and outer threads of the joints at both ends. In order to more clearly express the process steps and the effects obtained by implementing the present invention, the following examples are used to further illustrate.

[0017] The conventional diameter of non-magnetic drill collar used for oil drilling is between 79.4mm and 241.3mm, and the length is about 10m. This kind of extra-long pipeline is suitable for surface strengthening treatment in the prone position. The non-magnetic drill collar adopts fixed axis rotation mode during operation, and the rotation speed is selected between 5.0-10r / s. The sequence of implementing the shot peening of the inner and outer walls is not prioritized in principle. In this embodiment, the inner hole wall is shot peened first, and then the outer wall shot peened. After determining the process route, the type and spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com