Method for measuring yield strength of Q345 low alloy steel by using nonlinear ultrasonic technique

A non-linear ultrasonic and low-alloy steel technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as slow measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

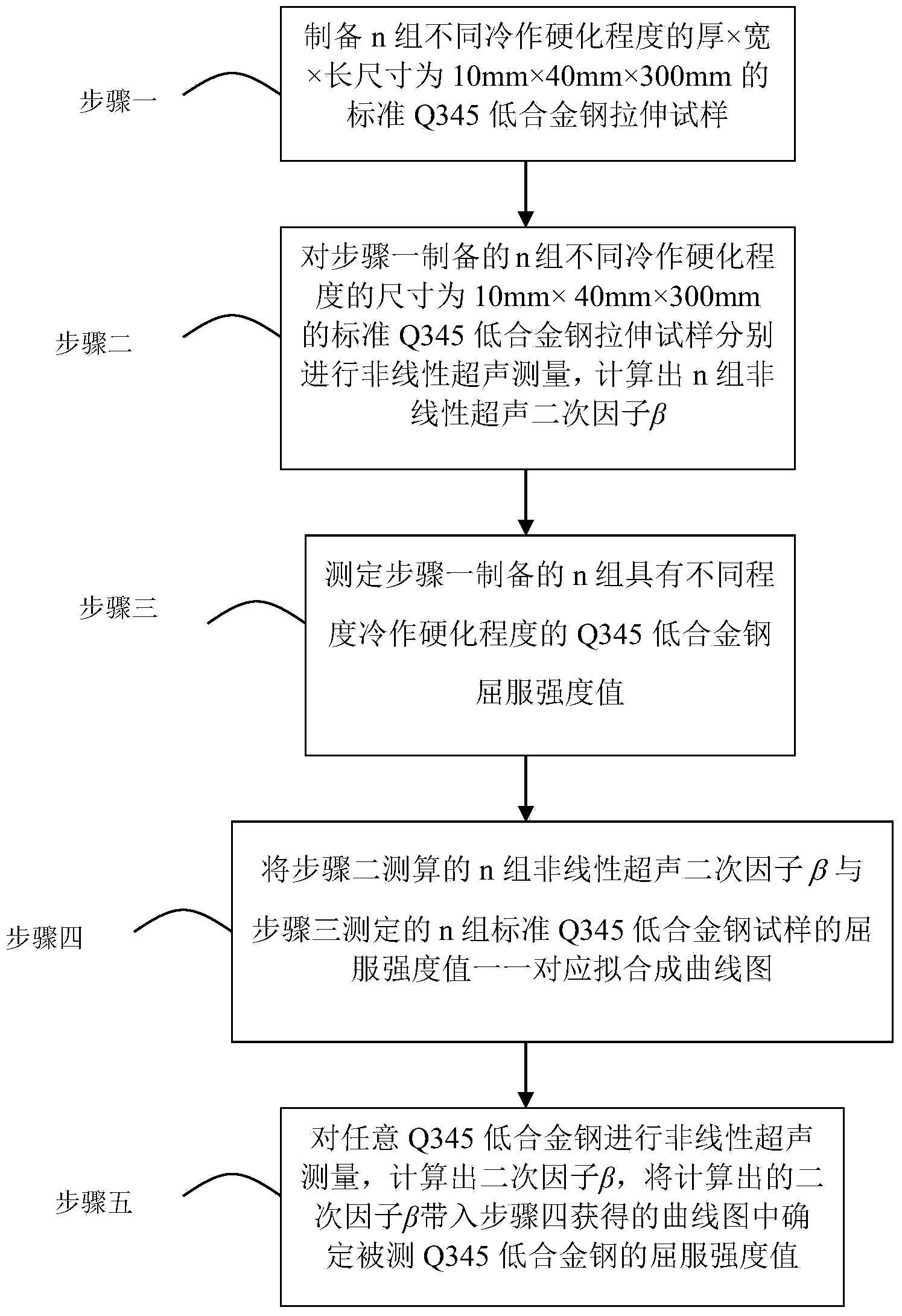

[0018] Specific embodiment one: a kind of method of this embodiment adopts nonlinear ultrasonic technology to measure the yield strength of Q345 low-alloy steel according to the following steps:

[0019] Step 1. Prepare n groups of standard Q345 low-alloy steel tensile specimens with thickness × width × length of 10 mm × 40 mm × 300 mm with different degrees of cold work hardening;

[0020] Step 2: Perform nonlinear ultrasonic measurements on the n groups of standard Q345 low-alloy steel tensile specimens prepared in step 1 with different cold work hardening degrees and the dimensions are 10mm×40mm×300mm, and calculate n groups of nonlinear ultrasonic quadratic factors beta;

[0021] Step 3, measuring the yield strength values of Q345 low-alloy steel with different degrees of cold work hardening degree for n groups prepared in step 1;

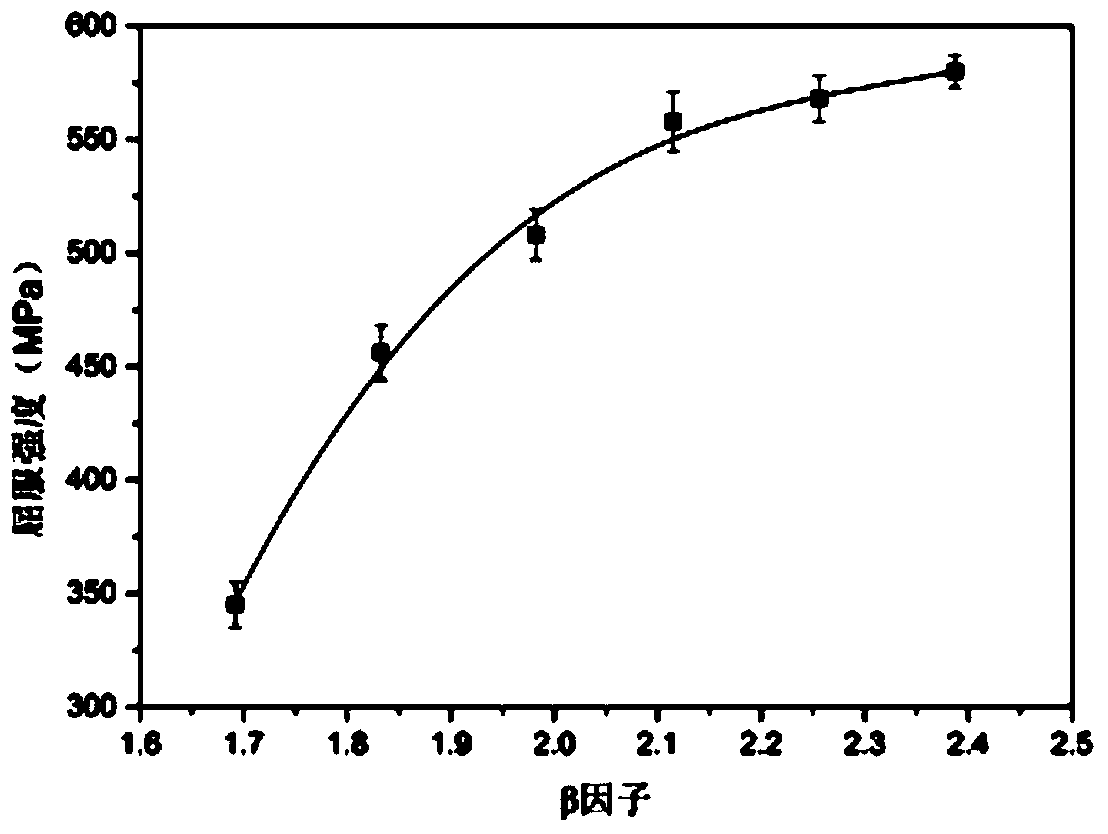

[0022] Step 4, the yield strength values of n groups of standard Q345 low-alloy steel samples measured by step 2 and n groups of non-line...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in the step 1, the standard Q345 low-alloy steel tensile test method with thickness × width × length of 10 mm × 40 mm × 300 mm in different cold hardening degrees is prepared for:

[0027] Select n groups of strip-shaped Q345 low-alloy steel samples with thickness×width×length of 20mm×80mm×300mm, and stretch these n groups of Q345 low-alloy steel samples with a tensile testing machine to obtain the thickness by 20mm ~ 12mm n groups of Q345 low alloy steel samples, wherein the thickness of the sample after deformation is 100% ~ 60% of the original thickness; then n groups of Q345 low alloy steel samples are made into n groups of different cold Standard Q345 low-alloy steel tensile test specimen with thickness × width × length dimensions of 10mm × 40mm × 300mm for hardening degree; where n≥6. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

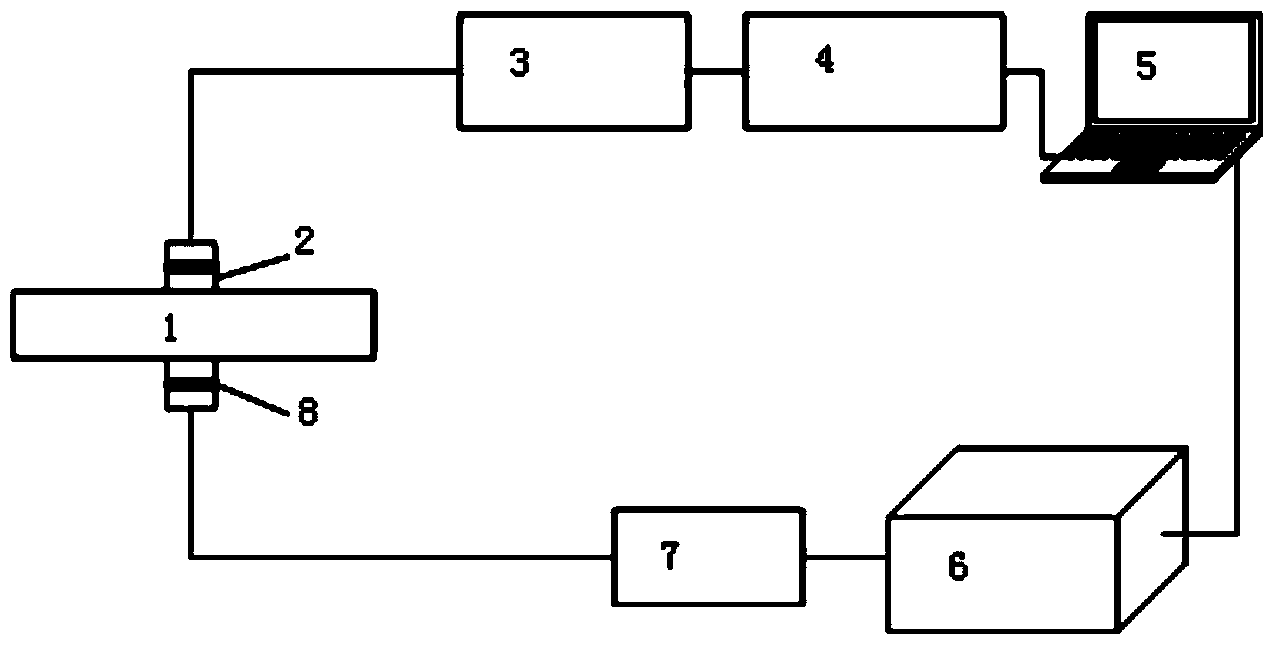

[0028] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is: the method of calculating nonlinear ultrasonic quadratic factor β in step two is as follows figure 2 :

[0029] (1) The computer sends an instruction to notify the nonlinear ultrasonic generator; after receiving the instruction, the ultrasonic generator sends a sine or cosine electrical signal with a frequency of 2MHz to 5MHz for more than 5 consecutive cycles;

[0030] (2) The electrical signal from the ultrasonic generator is filtered by a low-pass filter to filter out frequency waves above 20MHz;

[0031] (3) The filtered electrical signal reaches the single-frequency straight probe at the transmitting end. The single-frequency straight probe uses the piezoelectric effect to convert the electrical signal into a mechanical ultrasonic wave. The mechanical ultrasonic wave passes through the contact interface between the single-frequency st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com