ABS (acrylonitrile butadiene styrene) composite material for automobile and preparation method thereof

A technology for composite materials and automobiles, which is applied in the field of ABS composite materials for automobiles and its preparation. It can solve the problems that there is no clear theory to explain the unnotched impact strength and the increase of silver streaks, and achieve good heat resistance and unnotched impact performance. The effect of low production cost and high precision of product forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

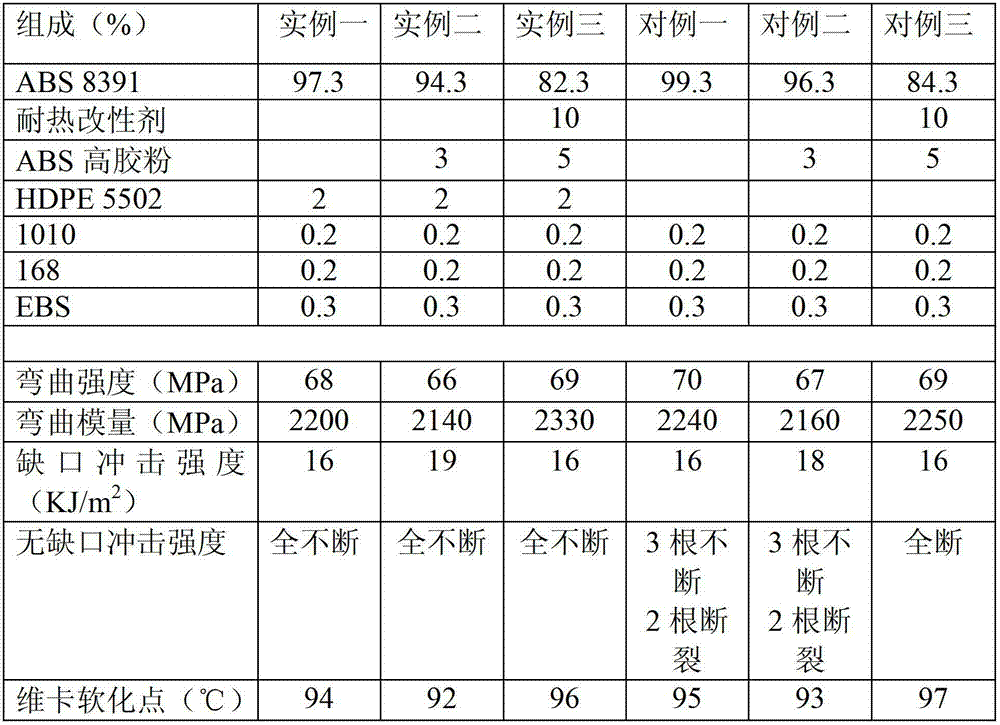

Embodiment 1

[0023] A preparation method of ABS composite material for automobiles, which has the following steps:

[0024] (1) In terms of weight percentage, after accurately weighing ABS 97.3%, HDPE 2%, antioxidant 10100.2%, antioxidant 1680.2% and lubricant 0.3%, pre-dry at 85-90°C;

[0025] (2) Put the dried material above into a high-speed mixer for dry mixing for 1 to 4 minutes, then put the mixed material into a twin-screw extruder, melt and extrude through the twin-screw extruder, cool, dry, and pelletize to obtain the finished product ;

[0026] The parameters of each segment of the automotive ABS composite material on the twin-screw extruder are set as follows: the temperature of the first zone is 200°C, the temperature of the second zone is 230°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 230°C, and the temperature of the fifth zone is 230°C , the temperature of the sixth zone is 230°C, the temperature of the seventh zone is 230°C, the te...

Embodiment 2

[0028] A method for preparing ABS composite materials for automobiles, the preparation steps and the place of origin of the materials are the same as in Example 1, and the formula is: ABS 94.3%, HDPE 2%, ABS high rubber powder 3%, antioxidant 10100.2%, antioxidant 1680.2 %, lubricant 0.3%.

Embodiment 3

[0030] A method for preparing ABS composite materials for automobiles, the preparation steps and origin of the materials are the same as in Example 1, the formula is: 82.3% ABS, 2% HDPE, 10% heat-resistant modifier, 5% ABS high rubber powder, anti-oxidant Agent 10100.2%, antioxidant 1680.2%, lubricant 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com