Mineral/long glass fiber reinforced polypropylene composite material and preparation method thereof

A long glass fiber and composite material technology, applied in polypropylene composite material and its preparation, mineral and long glass fiber reinforced polypropylene composite material and its preparation field, can solve the problem of mineral master batch and long glass fiber reinforced polypropylene master batch There are no problems such as reports, and the effects of good mechanical properties, good product forming accuracy, and good dimensional stability are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

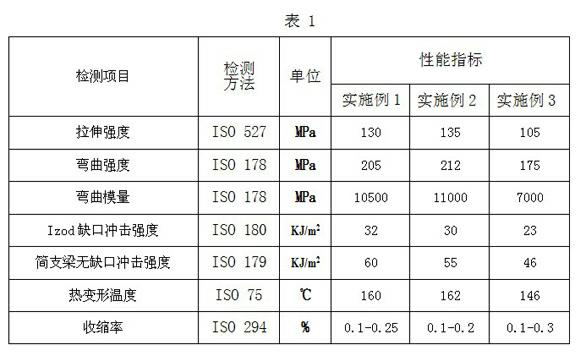

Embodiment 1

[0022] This example is a mineral and long glass fiber reinforced polypropylene composite material, which consists of the following components by weight percentage: 40% long glass fiber reinforced polypropylene masterbatch, 40% mineral masterbatch, and 20% polypropylene resin.

[0023] The dosages of polypropylene and long glass fiber in the long glass fiber reinforced polypropylene masterbatch are 50wt% and 50wt% respectively.

[0024] The mineral masterbatch is composed of the following components: polypropylene 25wt%, mineral 73.4wt%, antioxidant 0.6wt%, lubricant 1wt%. The mineral is talc, the antioxidants are 1010 and 168, and the lubricant is EBS.

[0025] The preparation method of mineral and long glass fiber reinforced polypropylene composite material is carried out according to the following steps:

[0026] ⑴ Add polypropylene, compatibilizer, and antioxidant to the mixer to make it fully mixed evenly, add the obtained mixture to the twin-screw extruder, and extrude t...

Embodiment 2

[0031] This example is a mineral and long glass fiber reinforced polypropylene composite material, which consists of the following components by weight percentage: 60% long glass fiber reinforced polypropylene masterbatch, 30% mineral masterbatch, and 10% polypropylene resin.

[0032] The amounts of polypropylene and long glass fibers in the long glass fiber reinforced polypropylene masterbatch are 40wt% and 60wt%, respectively.

[0033] The mineral masterbatch is composed of the following components: polypropylene 30wt%, mineral 66wt%, antioxidant 1wt%, lubricant 3wt%. The minerals are mica and calcium carbonate, the antioxidants are 1010 and 168, and the lubricant is EBS.

[0034] The preparation method of mineral and long glass fiber reinforced polypropylene composite material is carried out according to the following steps:

[0035] ⑴ Add polypropylene, compatibilizer, and antioxidant to the mixer to make it fully mixed evenly, add the obtained mixture to the twin-screw e...

Embodiment 3

[0040] This example is a mineral and long glass fiber reinforced polypropylene composite material, which consists of the following components by weight percentage: 50% long glass fiber reinforced polypropylene masterbatch, 20% mineral masterbatch, and 30% polypropylene resin.

[0041] The amounts of polypropylene and long glass fibers in the long glass fiber reinforced polypropylene masterbatch are 60wt% and 40wt%, respectively.

[0042] The mineral masterbatch is composed of the following components: polypropylene 40wt%, mineral 59.7wt%, antioxidant 0.1wt%, lubricant 0.2wt%. The mineral is wollastonite, the antioxidants are 1010 and 168, and the lubricant is EBS.

[0043] The preparation method of mineral and long glass fiber reinforced polypropylene composite material is carried out according to the following steps:

[0044]⑴ Add polypropylene, compatibilizer, and antioxidant to the mixer to make it fully mixed evenly, add the obtained mixture to the twin-screw extruder, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com