Manufacture method of high-precision carbon fiber composite antenna panel

An antenna panel and composite material technology, applied in the field of high-precision carbon fiber composite material antenna panel manufacturing, can solve the problems of low precision, heavy weight, long production cycle, etc., and achieve the effects of improved precision, light weight and good molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

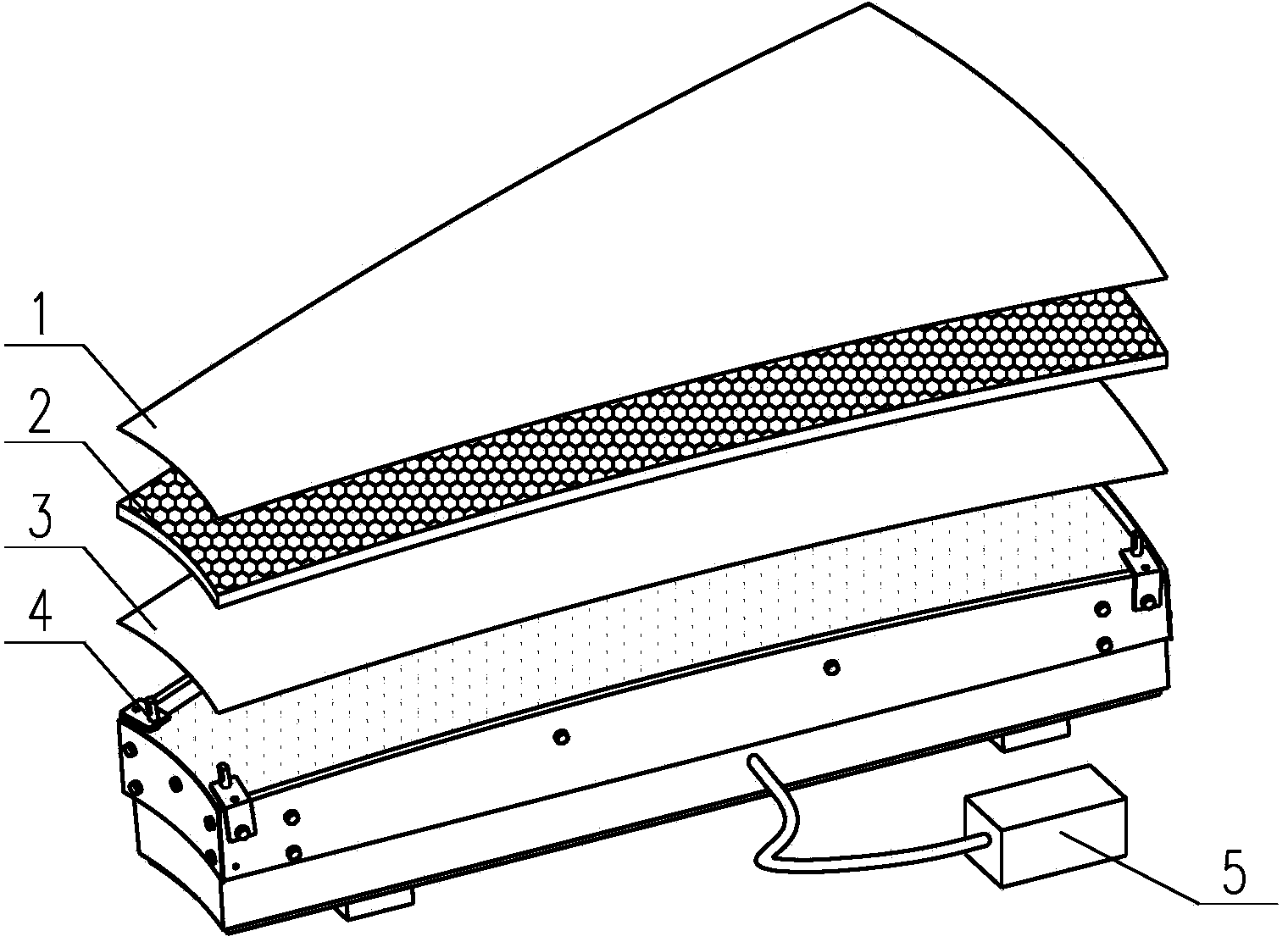

Image

Examples

Embodiment Construction

[0025] Describe the present invention below in conjunction with specific embodiment:

[0026] In this embodiment, the method for manufacturing a high-precision carbon fiber composite antenna panel adopts the following steps:

[0027] Step 1: Manufacture the skin mold according to the design drawing of the single antenna panel. The mold is the basis of composite material molding, and the mold material, structural form, processing accuracy, etc. directly affect the quality of the reflective surface. Since the mold is subjected to temperature changes from room temperature to about 150°C during the molding process. The thermal expansion and cold contraction of the mold body material will inevitably cause a certain internal stress on the part. Based on comprehensive analysis and calculation and referring to the experience of thermal deformation of molds in the past, nodular cast iron (QT600-3) was used to manufacture molds, and its linear expansion coefficient αl (20-200°C) was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com