High-precision laser additive and subtractive material combined manufacturing device

A technology for manufacturing devices and adding and subtracting materials, which is applied in the directions of manufacturing tools, additive manufacturing, and additive processing. It can solve the problems of low geometric dimension accuracy, large residual tensile stress, and poor surface quality of SLM forming parts, and achieve exquisite device design. , Improve stability, improve the effect of forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

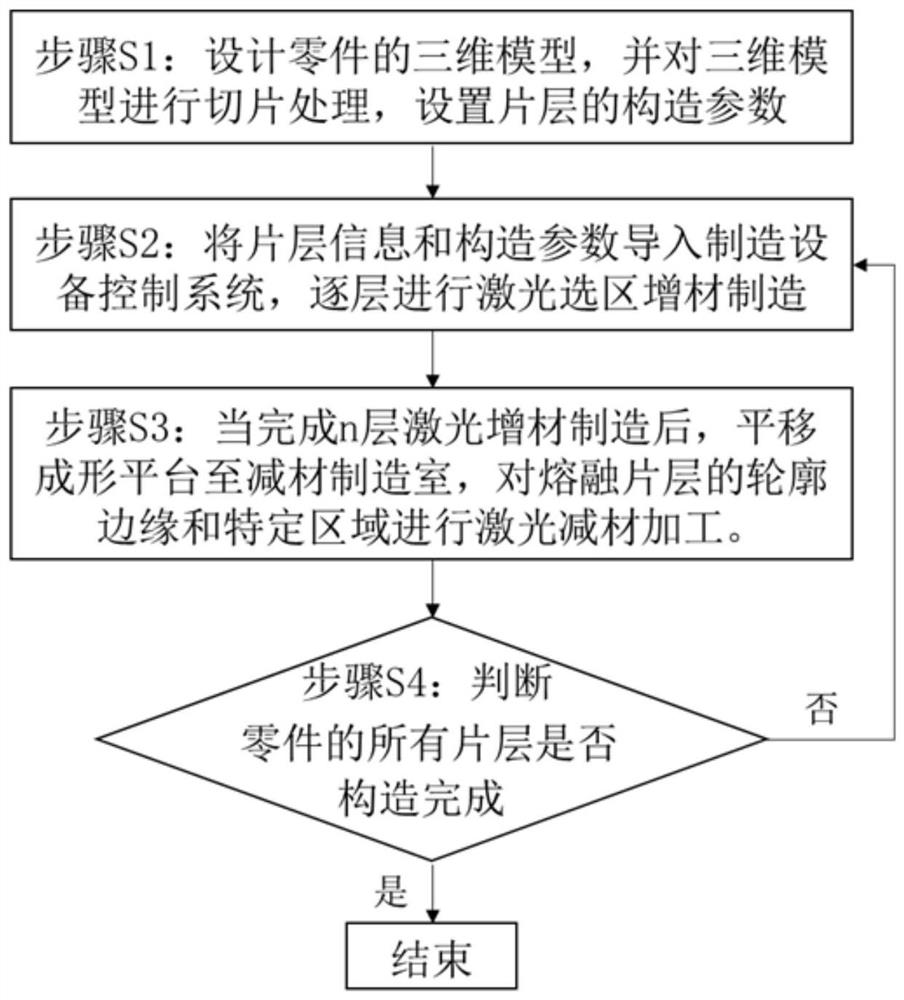

[0047] Below in conjunction with the accompanying drawings, the specific implementation of the present invention will be further elaborated, taking the manufacture of 316 stainless steel capillary as an example.

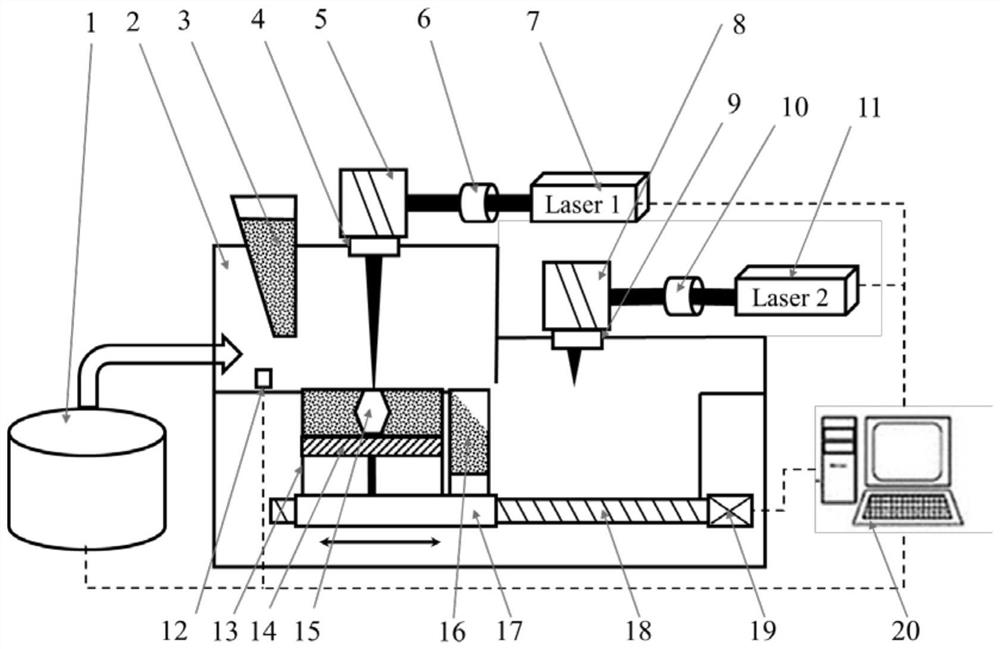

[0048] A composite manufacturing device for high-precision laser addition and subtraction materials, such as figure 1 As shown, it includes a sealed molding chamber 2, an inert protective gas source 1, a processing and molding platform, an optical path selection system and a control device 20 (computer);

[0049] The inert protective gas source 1 is connected to the sealing molding chamber 2 to provide inert protective gas for the sealing molding chamber 2;

[0050] The processing and molding platform is arranged in the sealing molding chamber 2, wherein the optical path selection system is arranged above the processing and molding platform, the sealing and molding chamber 2 is provided with a through hole communicating with the outside, and the through hole is arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com