Low-melting-point and low-crystallinity nylon 6 powder for SLS (Selective Laser Sintering) and preparation method of nylon 6 powder

A technology with low crystallinity and low melting point, applied in the field of nylon materials, can solve the problems of low crystallinity, low processing temperature, low melting point and crystallinity, etc., and achieve the effects of good molding accuracy, easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

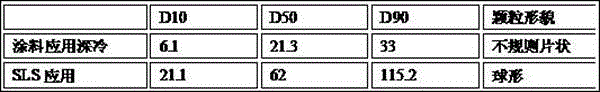

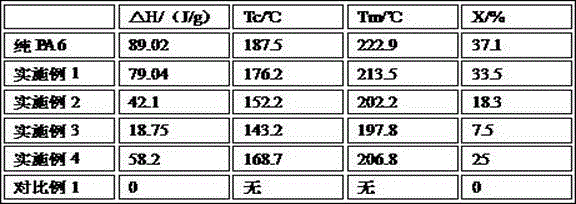

Embodiment 1

[0047] A preparation method of nylon 6 powder with low melting point and low crystallinity for SLS, comprising the following preparation steps:

[0048] Step 1. Weigh 98 parts by weight of nylon 6 pellets and 2 parts by weight of CaCl powder and mix them evenly after drying, extrude and granulate using a twin-screw extruder, the screw speed is 150r / min, and the temperature is controlled at 200°C;

[0049] Step 2, pulverize and sieve the granules obtained in step 1 to obtain powder particles with a particle size of 20 μm;

[0050] Step 3: Mix the powder particles obtained in step 2 with fumed silica and antioxidant 9228 in a weight ratio of 1:0.003:0.003, and sieve to obtain nylon 6 powder with a particle size of 20 μm.

Embodiment 2

[0052] A preparation method of nylon 6 powder with low melting point and low crystallinity for SLS, comprising the following preparation steps:

[0053] Step 1. Weigh 96 parts by weight of nylon 6 pellets and 4 parts by weight of CaSO4 powder, mix them evenly after drying, and extrude and granulate using a twin-screw extruder, the screw speed is 160r / min, and the temperature is controlled at 220°C;

[0054] Step 2, pulverize and sieve the granules obtained in step 1 to obtain powder particles with a particle size of 60 μm;

[0055] Step 3: Mix the powder particles obtained in Step 2 with fumed silica and antioxidant 1098 in a weight ratio of 1:0.004:0.004, and sieve to obtain nylon 6 powder with a particle size of 60 μm.

Embodiment 3

[0057] A preparation method of nylon 6 powder with low melting point and low crystallinity for SLS, comprising the following preparation steps:

[0058] Step 1. Weigh 94 parts by weight of nylon 6 pellets and 6 parts by weight of CaCl powder and mix them evenly after drying, and extrude and granulate by a twin-screw extruder, the screw speed is 170r / min, and the temperature is controlled at 250°C;

[0059] Step 2, pulverize and sieve the granules obtained in step 1 to obtain powder particles with a particle size of 80 μm;

[0060] Step 3: Mix the powder particles obtained in step 2 with fumed silica and antioxidant 9228 in a weight ratio of 1:0.005:0.005, and sieve to obtain nylon 6 powder with a particle size of 80 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com