Tire pasting drum with ultra-large expansion and shrinkage ratio

A technology of super-large expansion-shrinkage ratio and laminating drum, applied in the field of rubber tire machinery, can solve the problems of heavy lamination drum, easy loosening of adjusting nut, large sag of drum tile, etc. Defects, the effect of high molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

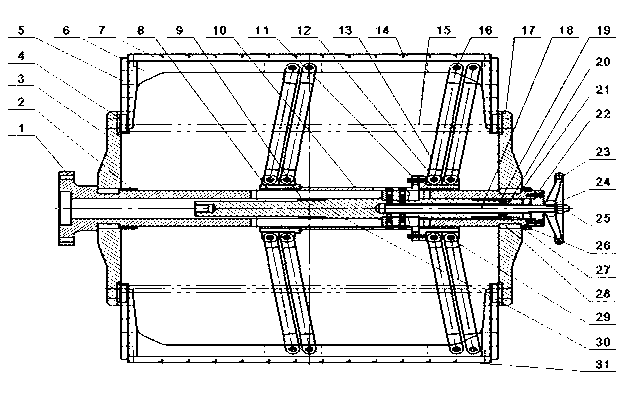

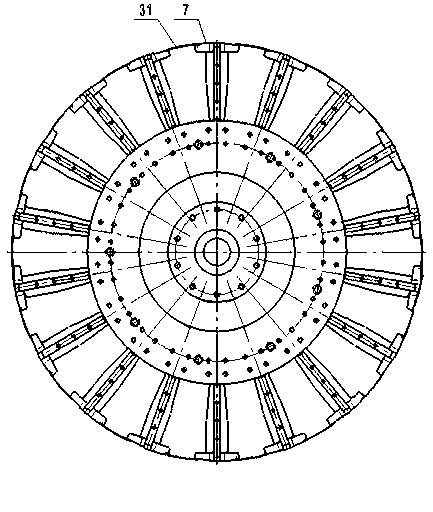

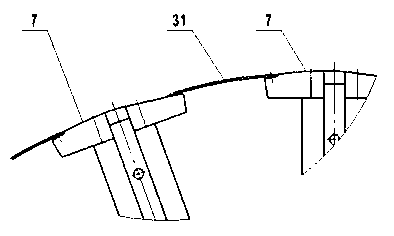

[0029] Such as figure 1 As shown, taking the two-stage molding of 24”~34” agricultural tires as an example, the tire fitting drum includes a power transmission mechanism, a drum shoe expansion and contraction mechanism, and a drum diameter adjustment mechanism.

[0030] The power transmission mechanism includes a hollow main shaft 1 connected with the molding machine and an inner shaft 30 connected with the cylinder of the molding machine; the hollow main shaft 1 is connected with a left transmission disc 3 and a right transmission disc 17 through a key 28, and the left transmission disc 3 and the right transmission disc 17 are fixed on the hollow main shaft 1. One group of stop bar 15 is housed between the right transmission disc 17, on the hollow main shaft 1 on the right side of the right transmission disc 17, repair washers 21 and snap-in 26 are housed, respectively install on the left transmission disc 3 and the right transmission disc 17 inboards. There is a group of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com