Radial tire building machine adopting two-stage once-through method

A radial tire and molding machine technology, which is applied in the field of tire manufacturing, can solve the problems that cannot fully meet the requirements of tire molding quality and production efficiency, and achieve the effects of reducing labor intensity of workers, uniform shrinkage, and improving molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

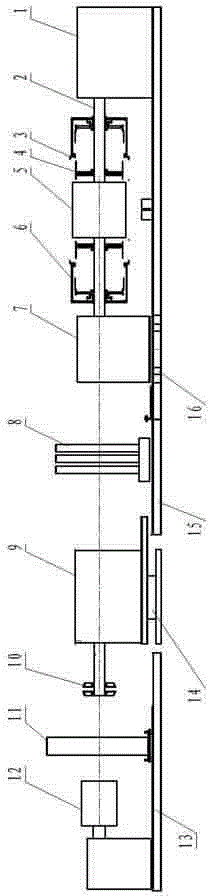

[0020] Such as figure 1 As shown, the belt feeding device and the tread feeding device convey the relevant tire components to the top of the bonding drum 12, which is made into a cylindrical belt tread by the bonding machine and the belt post-press roller The assembly cylinder, then the cylinder assembly is clamped by the transfer ring 11, and transferred to the carcass cylinder of the capsule chuck 10 of the second stage machine. The carcass cylinder is conveyed by the feeding device of the first stage forming machine to the inner liner and the carcass ply To the top of the forming drum, the laminating method is adopted for laminating, and then the finger-shaped steel claws in the finger-type wrapping device 4 are used for wrapping, the buckle device 3 is synchronized with the traveler, the capsule turn-up device 5 and the pusher plate push the package , And then laminating the sidewalls, etc.; in the laminating process, the lower pressure roller and the rear pressure roller d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com