A kind of integrally formed shock-absorbing sole or sole accessory and its production mold and production method

An integrated and accessory technology, applied in the direction of soles, other household appliances, footwear, etc., can solve the problems of inability to fit with the shoe material, not wear-resistant, easy to tear materials, etc., to solve the problem of inability to fit and easy to tear , reduce production cost, combine with good transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

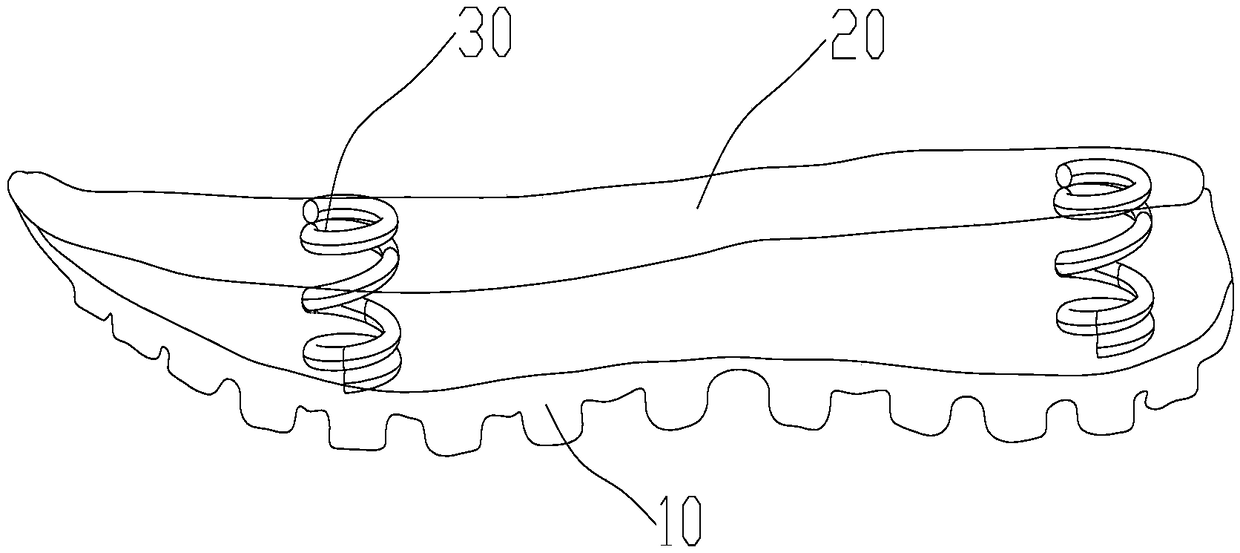

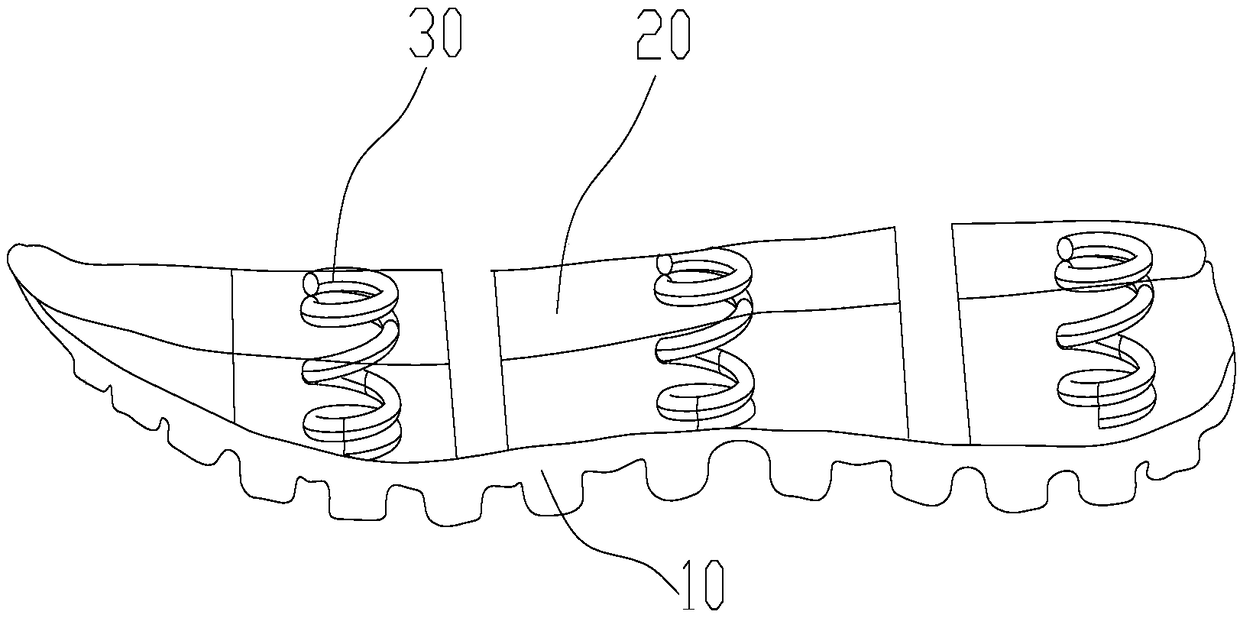

[0049] like Figure 1-2 As shown, a kind of one-piece shock-absorbing shoe sole or shoe sole accessory comprises big bottom 10, at least one shock-absorbing material layer 20 and TPU film wrapping layer; The TPU film wrapping layer wraps the side surface of the outsole 10, the top surface of the outsole 10, the side surface of the shock-absorbing material layer 20 and the top surface of the shock-absorbing material layer 20, that is to say, except that the bottom surface of the outsole 10 is not covered by the TPU Outside the coating of the film wrapping layer, all the wall surfaces of the sole are wrapped by the TPU film wrapping layer; the outsole 10, the shock-absorbing material layer 20 are integrally formed with the TPU film wrapping layer; the thickness of the shock-absorbing material layer 20 is greater than that of the large The thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com