Patents

Literature

31results about How to "Meet the needs of different purposes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble polyvinyl alcohol fibre and preparation technique thereof

InactiveCN101177800AReduce energy consumptionOptimize and shorten the production processArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentBreaking strengthHigh energy

The invention relates to a water-soluble polyvinyl alcohol fiber and a preparation method thereof. The water-soluble polyvinyl alcohol fiber provided by the present invention has the following characteristic parameters: fiber dry breaking strength ≥ 5cN / dtex, dry breaking elongation 10-20%, water solubility temperature 60-90 DEG C, single fiber fineness 1.0-8dtex, number of crimps 8 to 12 pieces / 25mm. The invention overcomes the shortcomings of the existing method that the technical process is long, the fibers are subjected to secondary drying, and the production energy consumption is high, and the performance of the prepared water-soluble polyvinyl alcohol fibers is improved to some extent.

Owner:HUNAN XIANGWEI

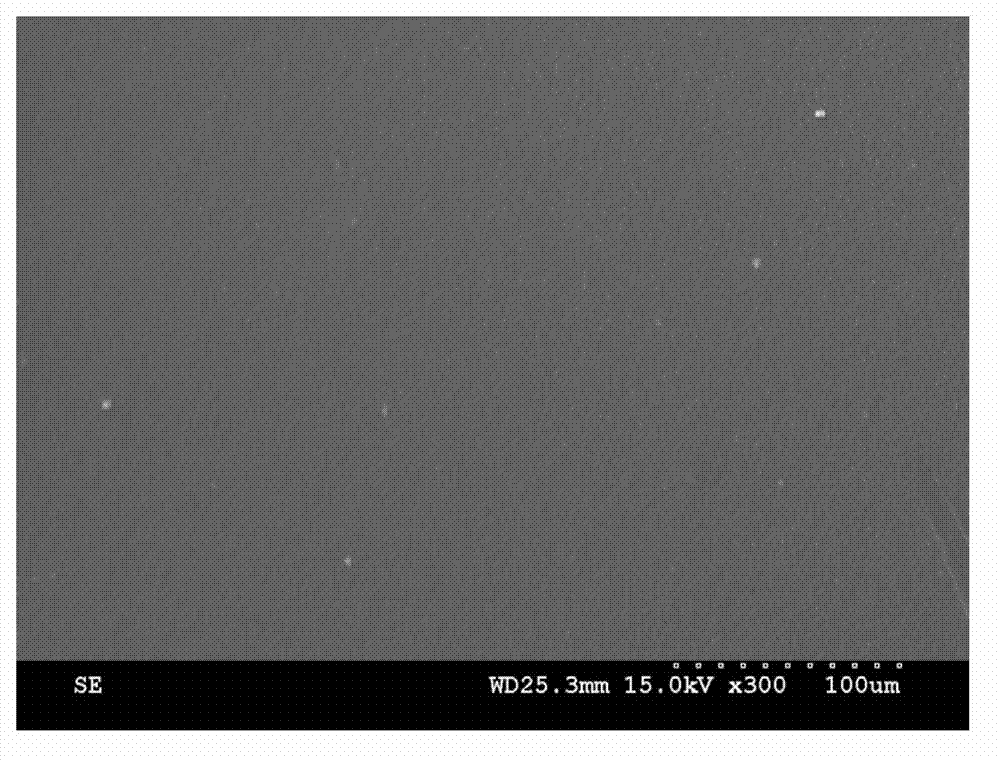

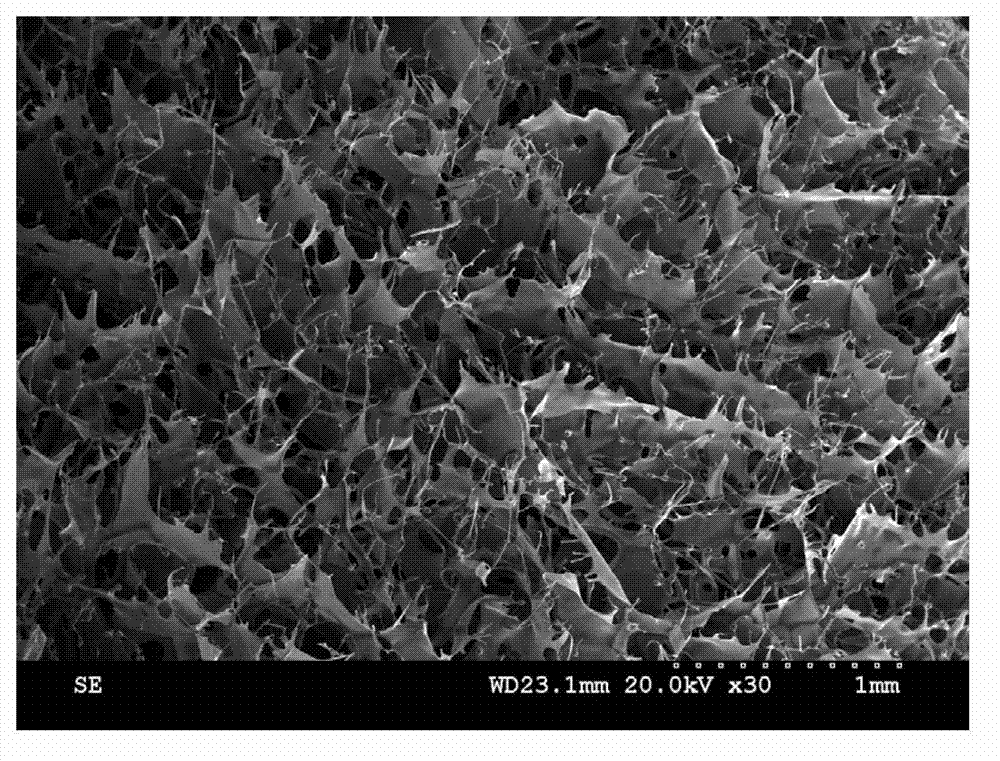

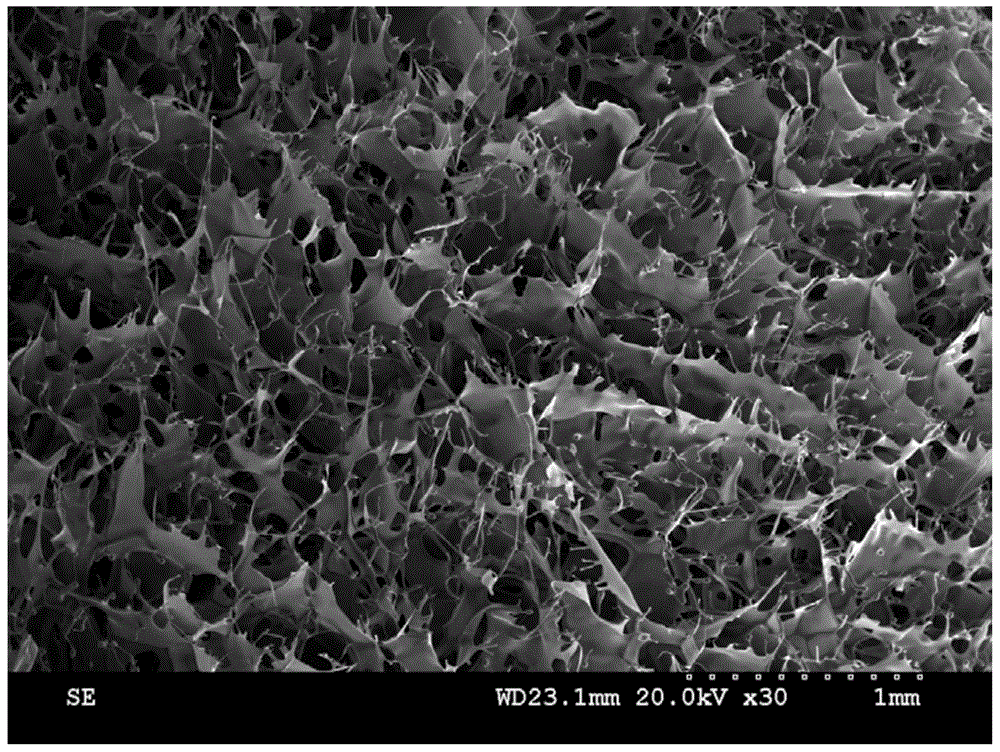

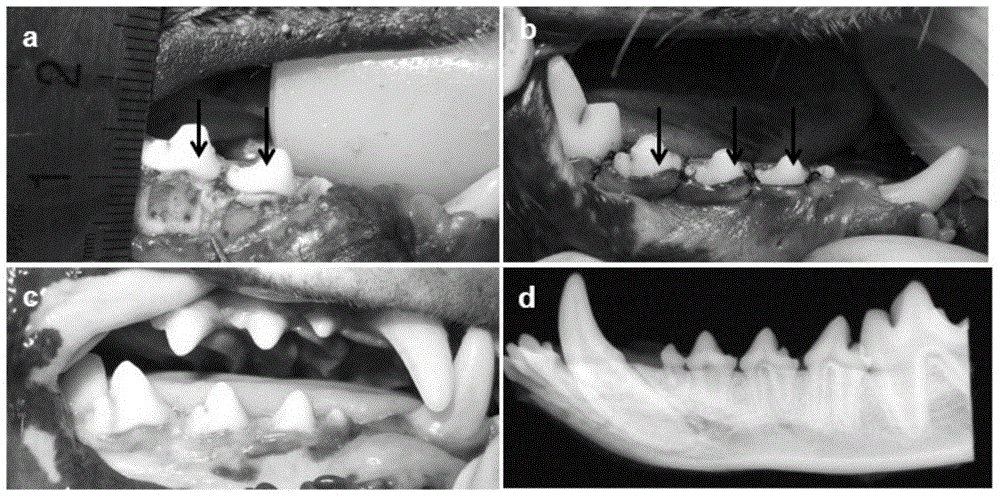

Stent type silk fibroin film insoluble in water, and preparation and application of stent type silk fibroin film

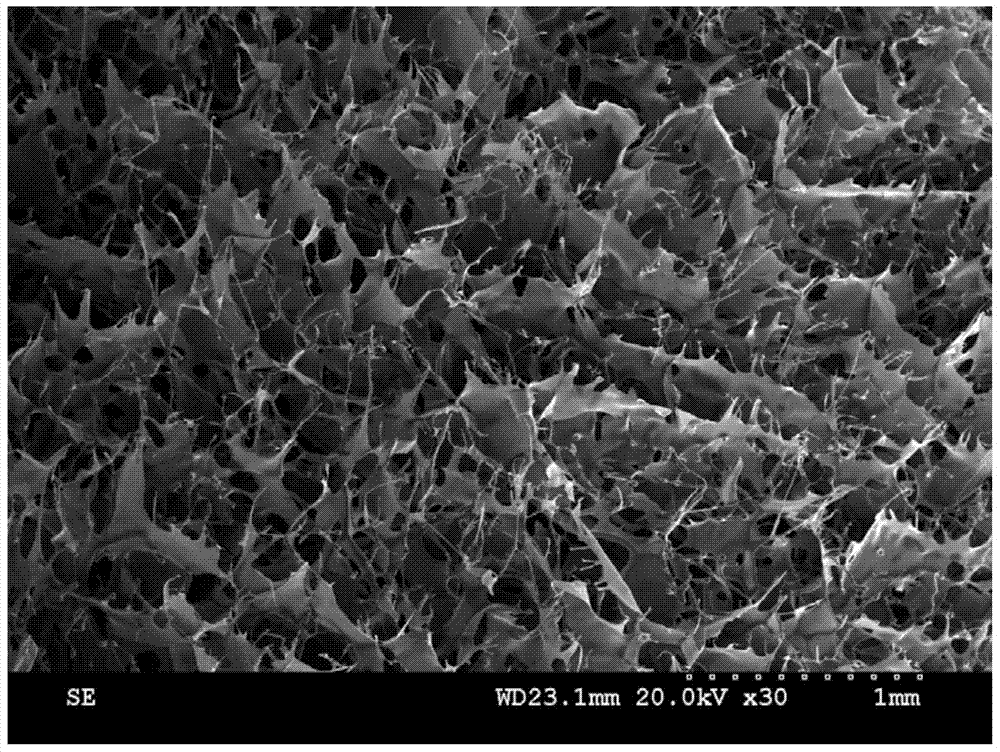

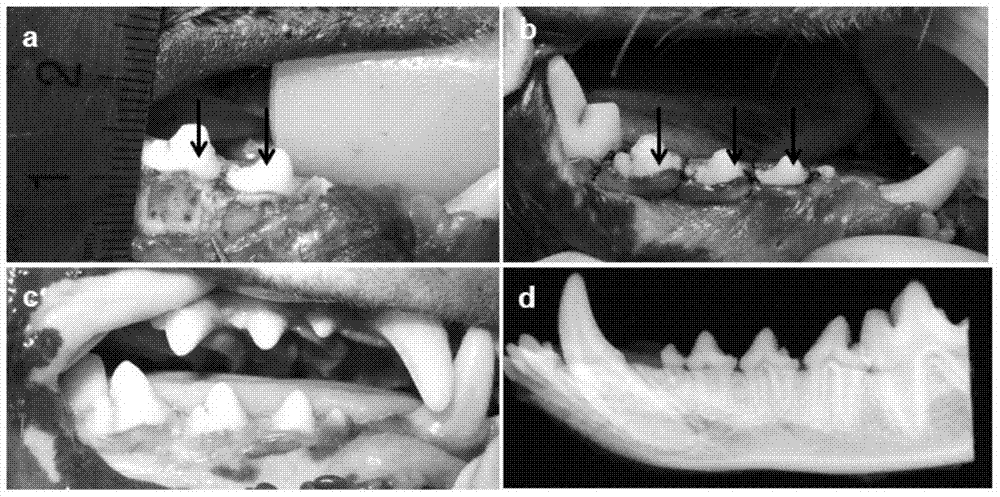

InactiveCN102847194AEasy to fixPromote ingrowthSurgeryAbsorbent padsMedicineBiocompatibility Testing

The invention discloses a stent type silk fibroin film insoluble in water, and preparation and application of the stent type silk fibroin film. A preparation method includes the steps of placing silk fibroin solution in a smooth, flat and horizontal mold, and obtaining a basilar film by humid and heat crosslinking; and laying the silk fibroin solution on the surface of the basilar film and forming the stent type silk fibroin film insoluble in water after freezing, drying and humid and heat crosslinking. Silk fibroin is used as a raw material, and biocompatibility is good; a preparation process is non-toxic and environment-friendly, and the thickness of the film and the aperture of a stent layer are easy to control; the film is soft in a moist environment, the basilar film is compact, and cells, microorganisms and biomacromolecules cannot penetrate through the basilar film; the stent layer is in the shape of a porous sponge, and is beneficial to fixation of the film, hemostasis of a wound and regeneration of transmitting tissues; and the film has a wide market in the field of anti-adhesive films and artificial film patches.

Owner:ZHEJIANG XINGYUE BIOTECH

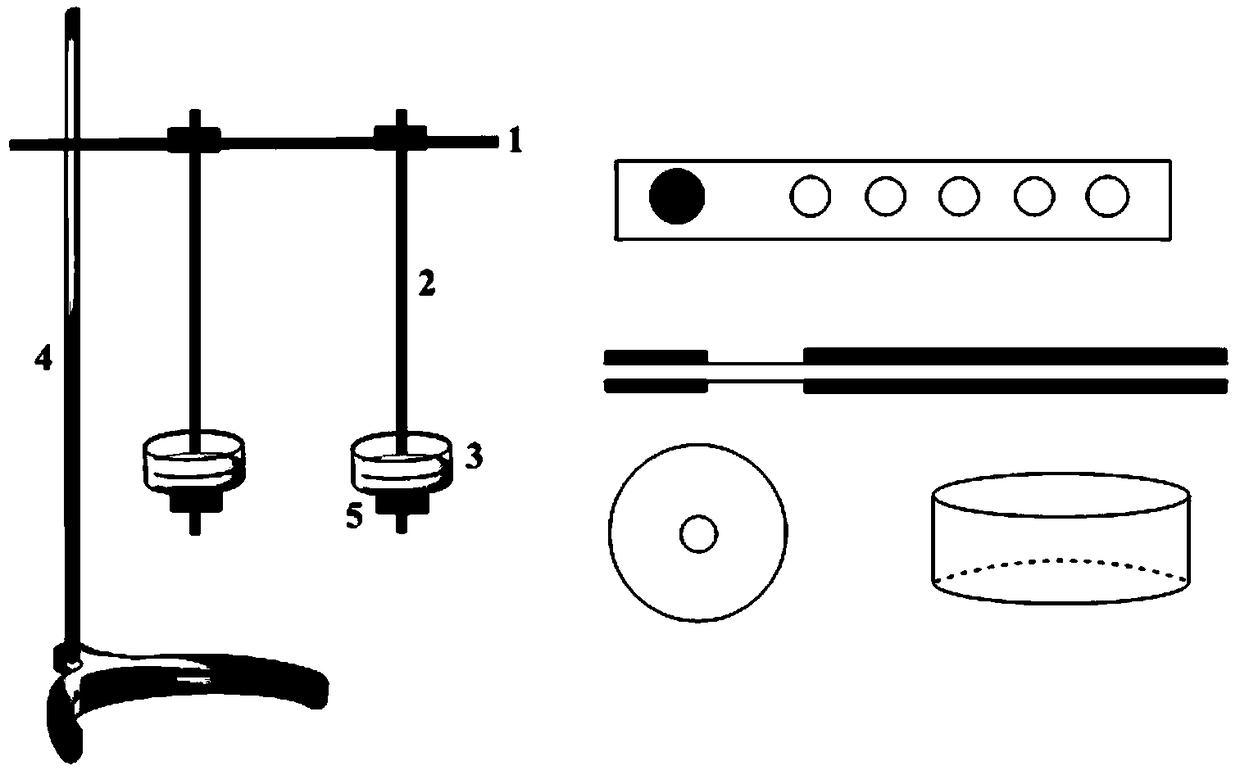

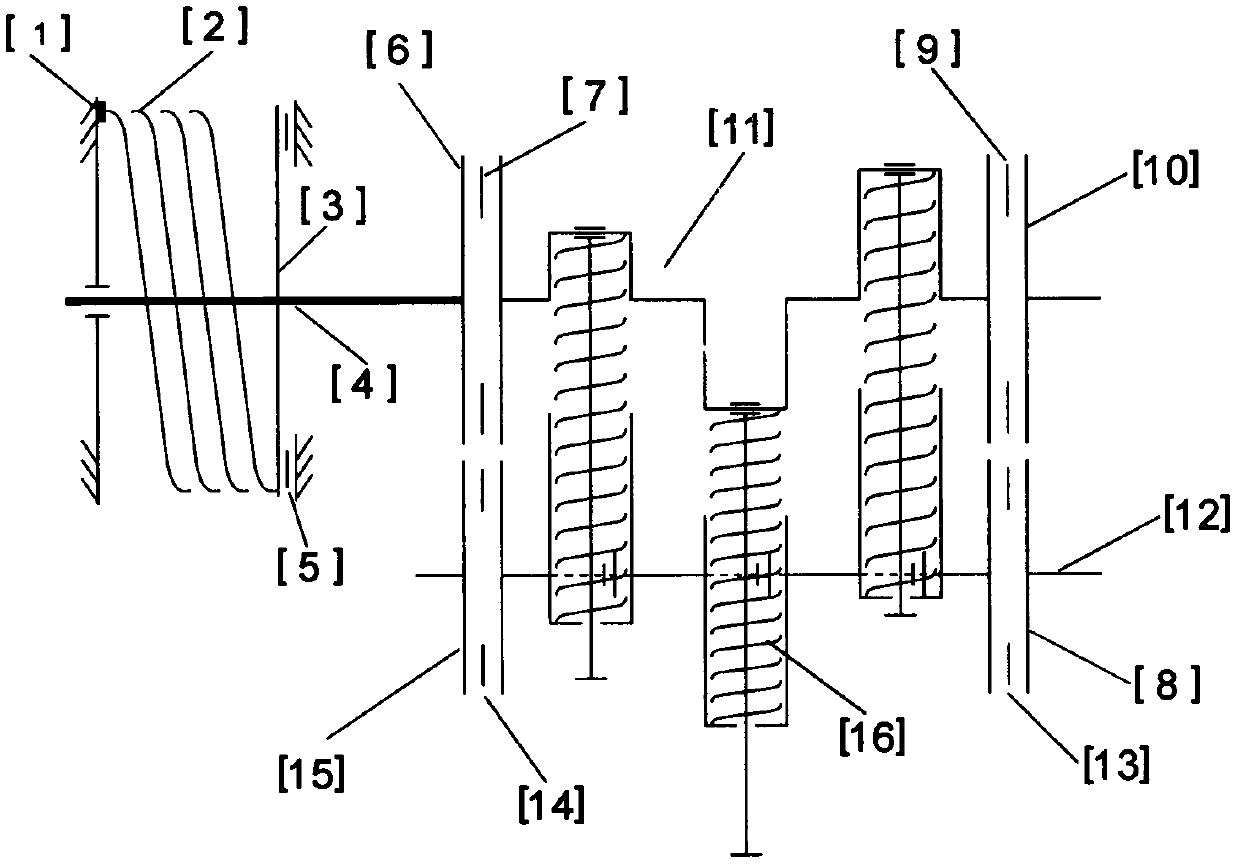

Controllable elastic energy release and recovery system

The invention discloses a controllable elastic energy release and recovery system, wherein a certain amount of coil springs (or other elements or components with elastic deformation) are used as an energy storage mechanism of the system, and appropriate auxiliary devices such as transmissions (and reversing mechanisms) are equipped. Under the control of a control system, through the speed variation and torque variation of each transmission and the reversing of the reversing mechanisms, the coil springs not only can store the recoverable energy, but also can release the stored energy as required, and the energy release and recovery tasks are completed, furthermore when the output ends of the coil springs can be kept at the higher rotation speed, not only can two ends of each coil spring rotate at the same direction at different rotation speeds, the energy release or recovery speed of the coil springs can be lowered, but also two ends of each coil spring can rotate at the opposite directions, the energy release or recovery speed of the coil springs can be improved, thus the system can operate normally within the greater variable range of torque for the coil springs, the energy release and recovery tasks are completed better, and the energy utilization ratio is improved.

Owner:怀化沃普环保科技有限公司

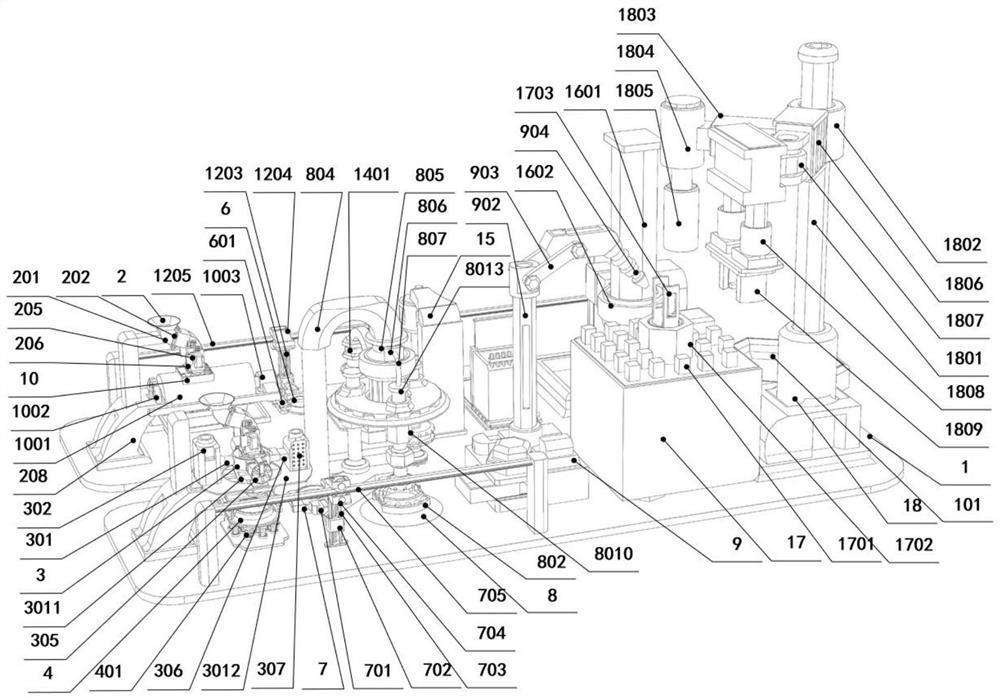

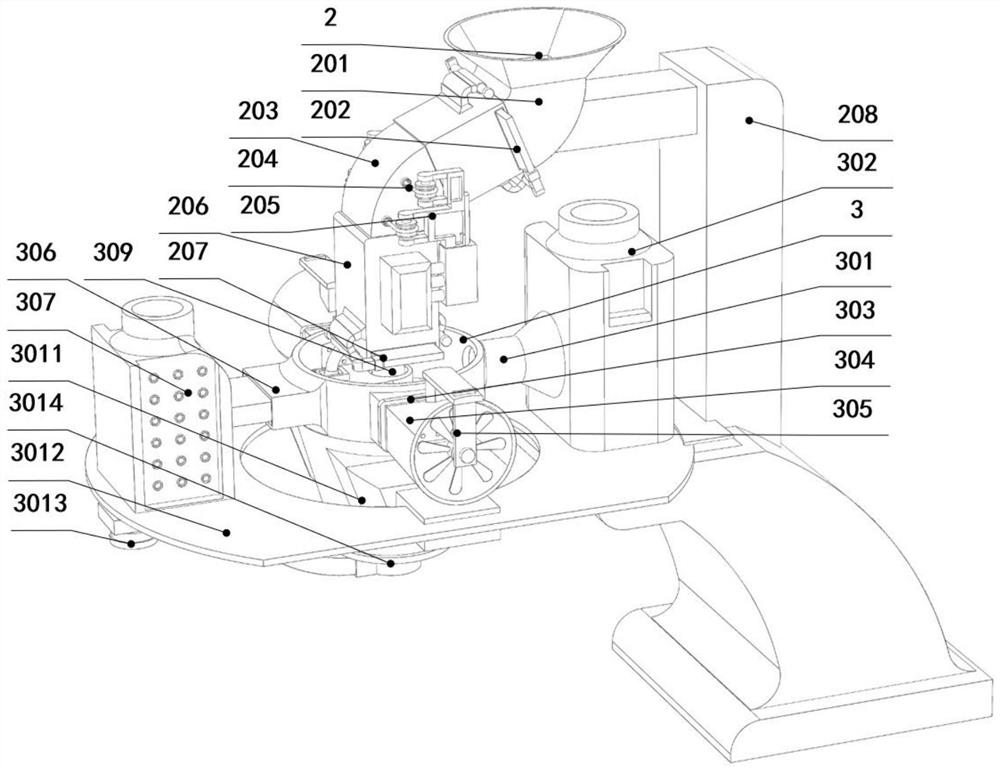

Method of preparing high-temperature nickel-based alloy porous material by 3DP (three-dimensional printing) and aftertreatment process

ActiveCN109807320AMeet the needs of different purposesLow costAdditive manufacturing apparatusPore distributionPolyvinyl alcohol

The invention discloses a method of preparing a high-temperature nickel-based alloy porous material by 3DP (three-dimensional printing) and an aftertreatment process. The method comprises the following steps of: step A. mixing powder, to be specific, fully mixing a certain proportion of metal powder such as Ni, Cr, and Fe with polyvinyl alcohol powder; step B. carrying out macroscopic direct pore-forming, to be specific, designing a three-dimensional model being of a porous structure by three-dimensional design software according to the appearance feature, porosity, pore distribution law and pore shape and size design requirements of the porous material; step C. preparing the porous material by 3DP, to be specific, 3DP equipment receives a printing program, and sets printing parameters tostart printing; step D. removing residual powder, to be specific, firstly taking out a rough blank from a powder stack, and then removing the residual powder on the rough blank; step E. debonding andatmosphere sintering treatment, to be specific, sending the rough blank to a muffle surface for debonding and atmosphere sintering; step F. carrying out electrochemical corrosion, to be specific, carrying out electrochemical corrosion treatment on the sintered nickel-based porous material; step G. carrying out cryogenic treatment, to be specific, putting a workpiece in a cryogenic device for cryogenic treatment; and step H. completing the preparation and aftertreatment of the high-temperature nickel-based alloy porous material.

Owner:NANTONG INST OF TECH

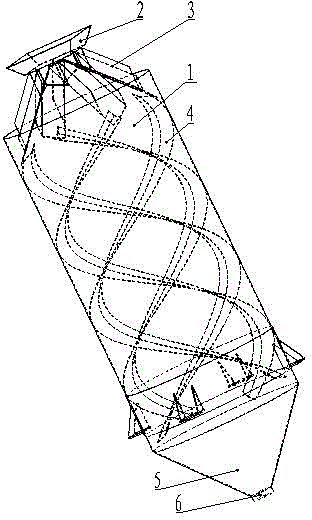

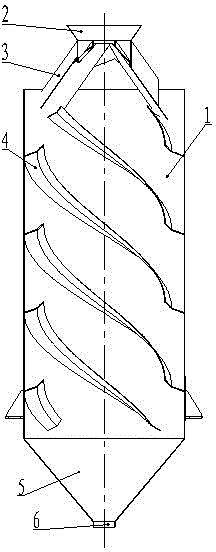

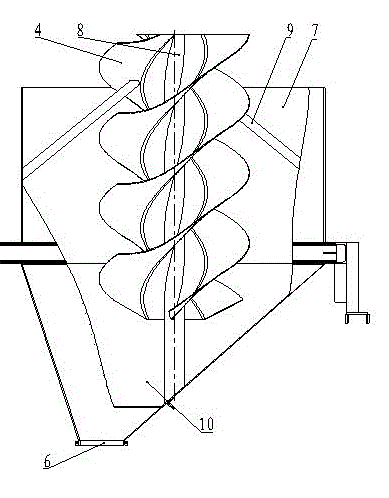

Storage bin provided with spiral slideway

The invention relates to a storage bin provided with a spiral slideway. According to different purposes, the cross section of the storage bin can be in a circular or square structure. For the storage bin with the circular section, a material inlet and a material distributing chute are connected and fixed on a storage bin housing, and the lower part of the material distributing chute is aligned with the spiral slideway which is uniformly distributed along the cross section of the storage bin. In a process of adding materials into the storage bin, the materials drop into the spiral slideway through the material inlet and the material distributing chute, and then slowly slide downwards along the spiral slideway. For the storage bin with the square section, the spiral slideway is arranged on a central cylinder of the storage bin, so that the materials directly slide downwards slowly through the spiral slideway. Through the spiral slideway, the materials slowly drop, thereby avoiding direct impact due to the vertical drop of the materials and reducing broken materials. The storage bin is used for preventing the materials from being broken, and has the advantages of simple structure and low manufacturing cost.

Owner:ZHENGZHOU UNIV +1

Processing method of shale oil

InactiveCN102079990AReduce viscosityImprove plasticityTreatment with plural serial refining stagesHydrocarbon oils refiningEconomic benefitsAtmospheric pressure

The invention discloses a processing method of shale oil, which comprises the following steps: after mixing shale oil and an extracting agent, heating up, and starting to stir so that the shale oil and the extracting agent are thoroughly mixed and are thoroughly in contact with each other; stopping stirring, standing so that the extract phase and the raffinate phase stratify, and separating the extract phase and the raffinate phase; and respectively distilling the extract phase and the raffinate phase to respectively obtain extract oil and the extracting agent, and raffinate oil and the extracting agent, and recovering the extracting agent. The method disclosed by the invention is simple and easy to operate, and the reaction conditions are mild; and the method can be carried out under theconditions of atmospheric pressure and low temperature, does not need the participation of the catalyst, and thus, has the advantages of low input cost and obvious economic benefit. Meanwhile, the method can be used for generating multiple products, such as extract oil composed of light and heavy components respectively for preparing non-hydrocarbon compounds and asphalt products, and raffinate oil which can be directly used as the raw material for catalytic cracking, thereby increasing the added value of the products. The heavy component of the extract oil has the advantages of low viscosity, high plasticity and high temperature sensibility, and can be blended into asphalt of different designations to satisfy the demands for different purposes.

Owner:抚顺欧力石化有限公司

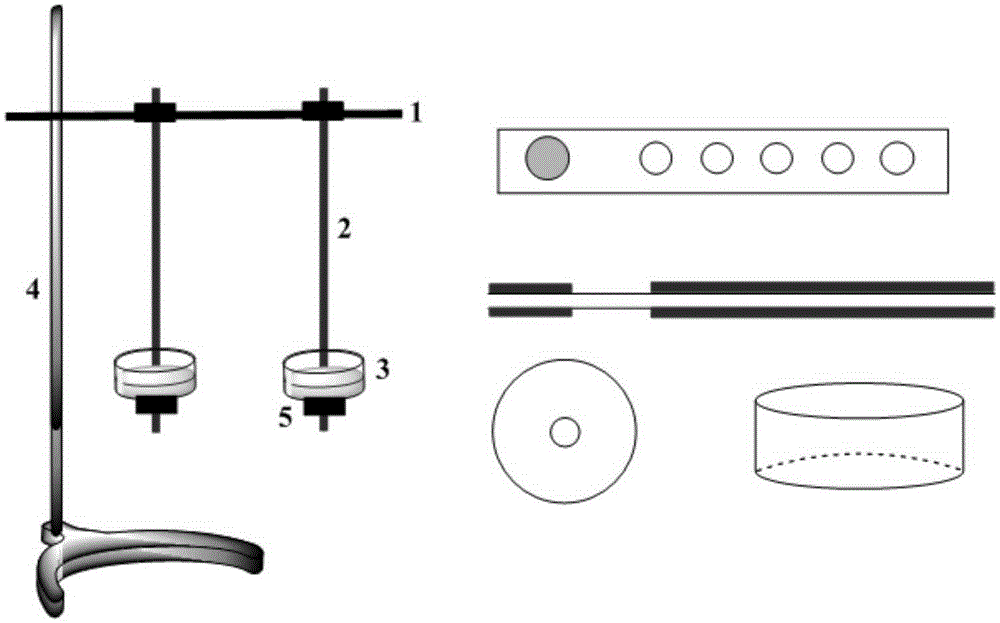

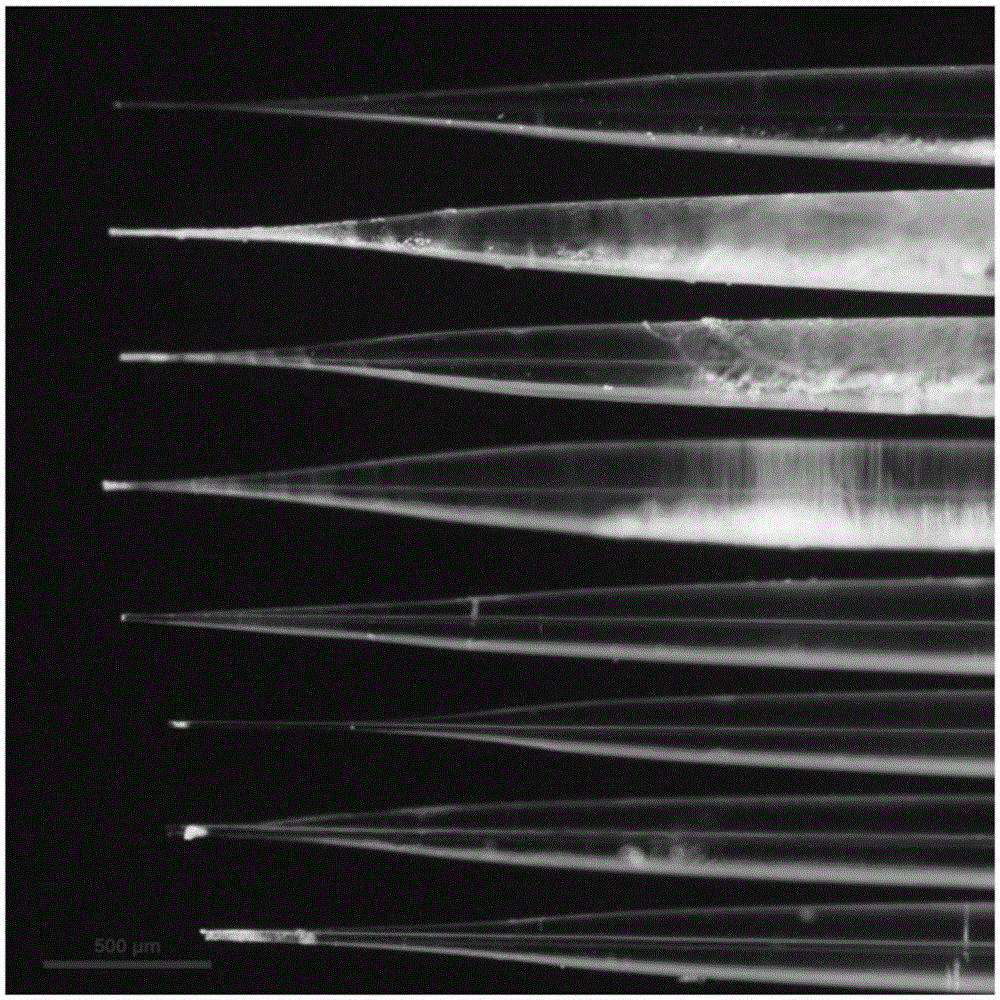

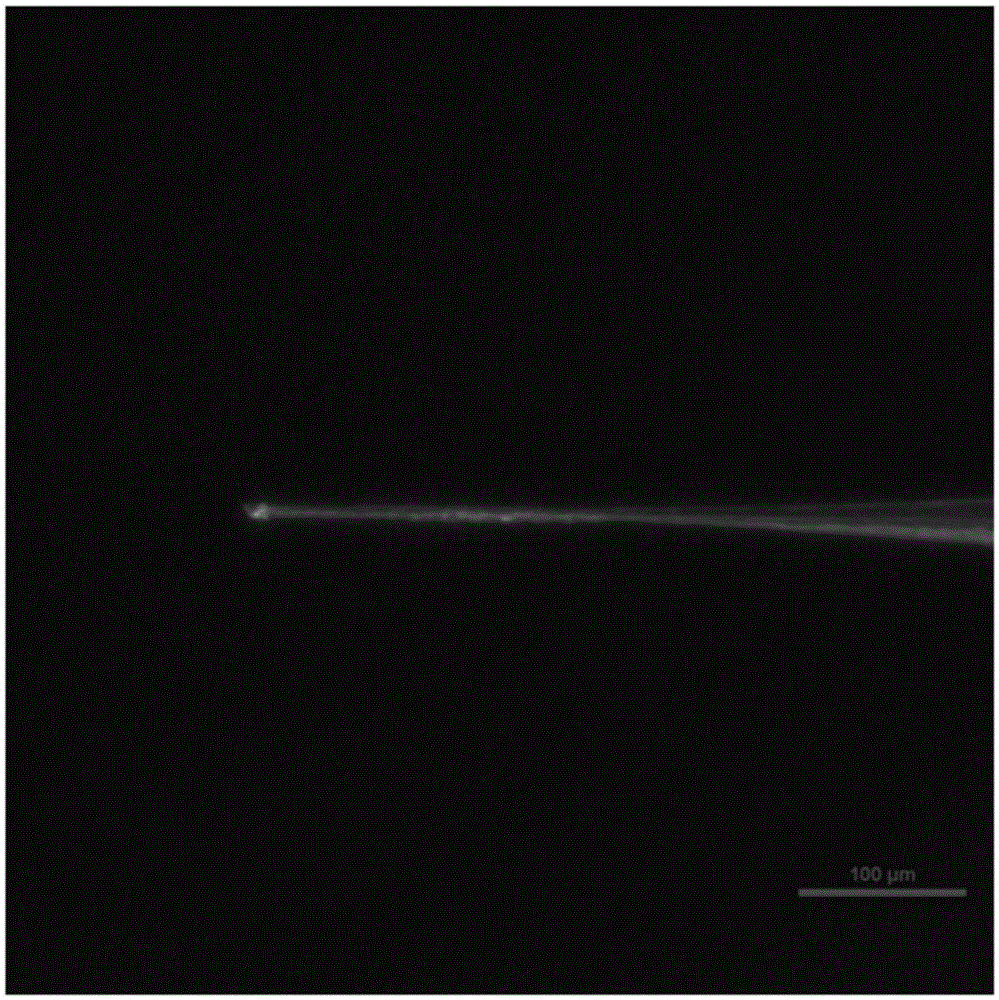

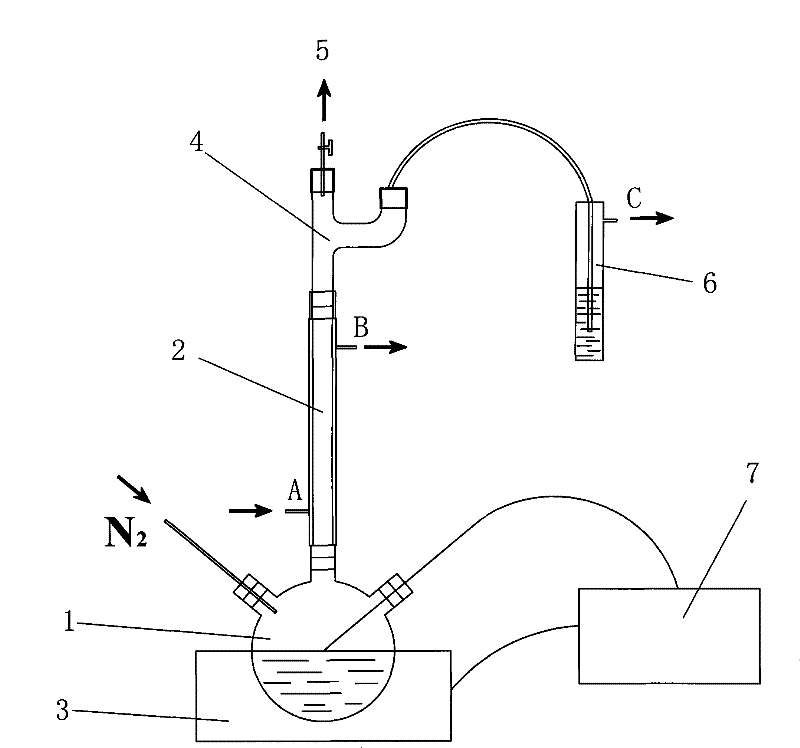

Method for preparing quartz needle by etching capillary tube by hydrofluoric acid

ActiveCN106486336ASimple and fast operationReduce usageSamples introduction/extractionMaterial analysis by electric/magnetic meansHydrofluoric acidCapillary Tubing

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

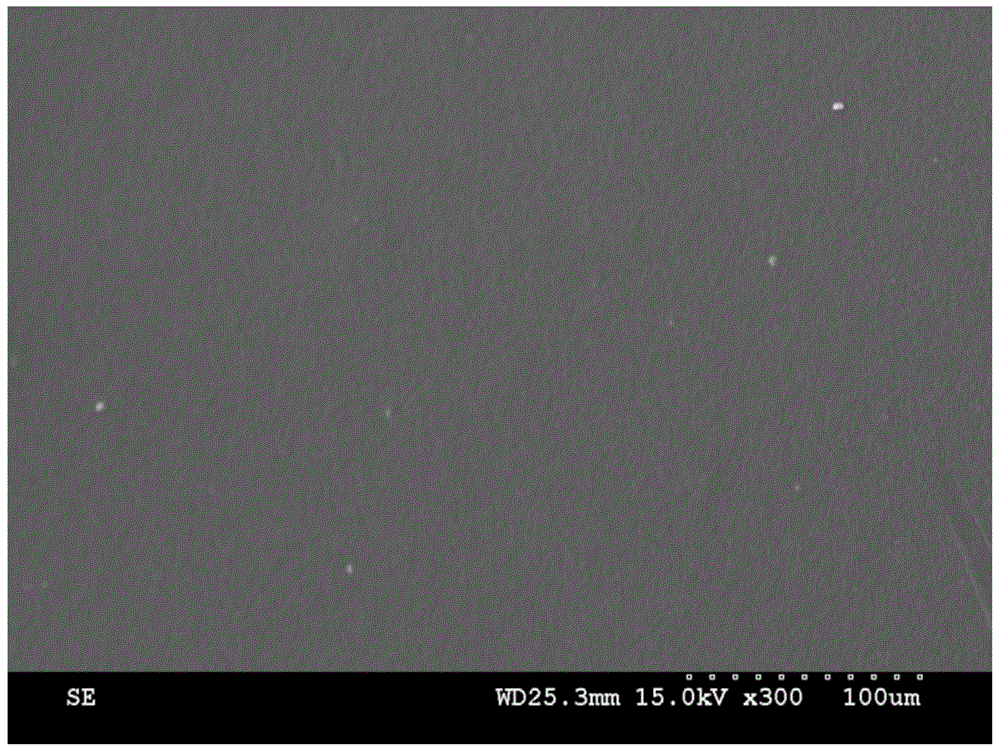

Stent-type silk fibroin film insoluble in water as well as preparation and application of silk fibroin film

ActiveCN103536963AEasy to fixPromote ingrowthSurgeryAbsorbent padsInsertion stentBiocompatibility Testing

The invention discloses a stent type silk fibroin film insoluble in water, and preparation and application of the stent type silk fibroin film. A preparation method includes the steps of placing silk fibroin solution in a smooth, flat and horizontal mold, and obtaining a basilar film by humid and heat crosslinking; and laying the silk fibroin solution on the surface of the basilar film and forming the stent type silk fibroin film insoluble in water after freezing, drying and humid and heat crosslinking. Silk fibroin is used as a raw material, and biocompatibility is good; a preparation process is non-toxic and environment-friendly, and the thickness of the film and the aperture of a stent layer are easy to control; the film is soft in a moist environment, the basilar film is compact, and cells, microorganisms and biomacromolecules cannot penetrate through the basilar film; the stent layer is in the shape of a porous sponge, and is beneficial to fixation of the film, hemostasis of a wound and regeneration of transmitting tissues; and the film has a wide market in the field of anti-adhesive films and artificial film patches.

Owner:ZHEJIANG XINGYUE BIOTECH

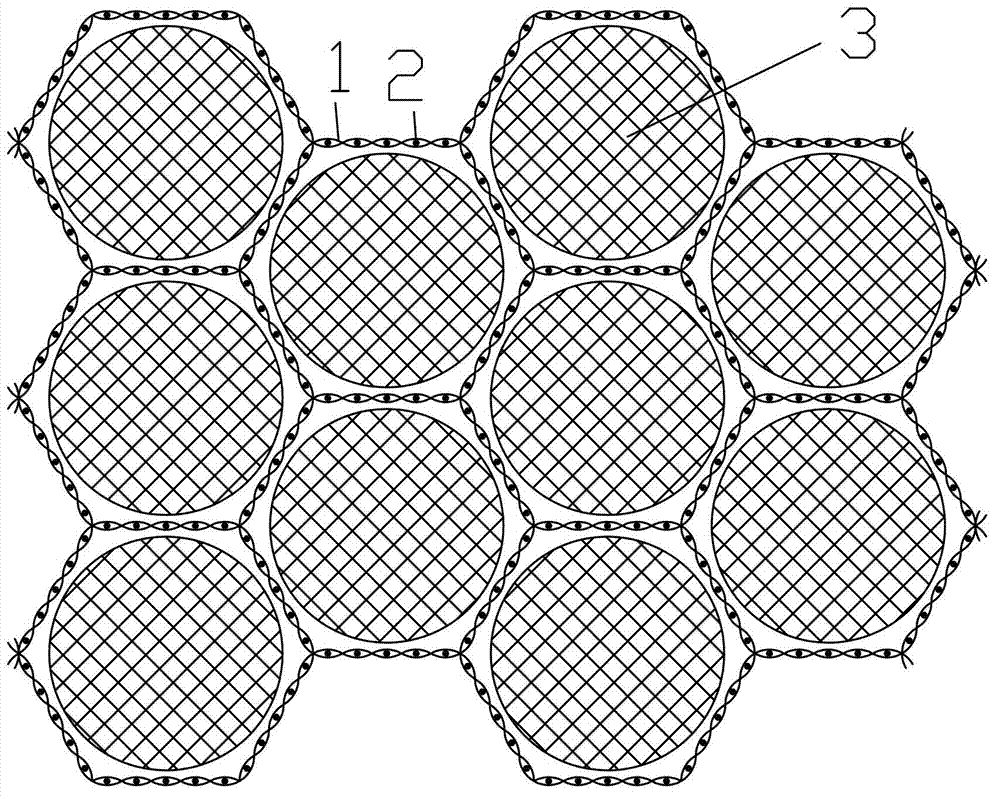

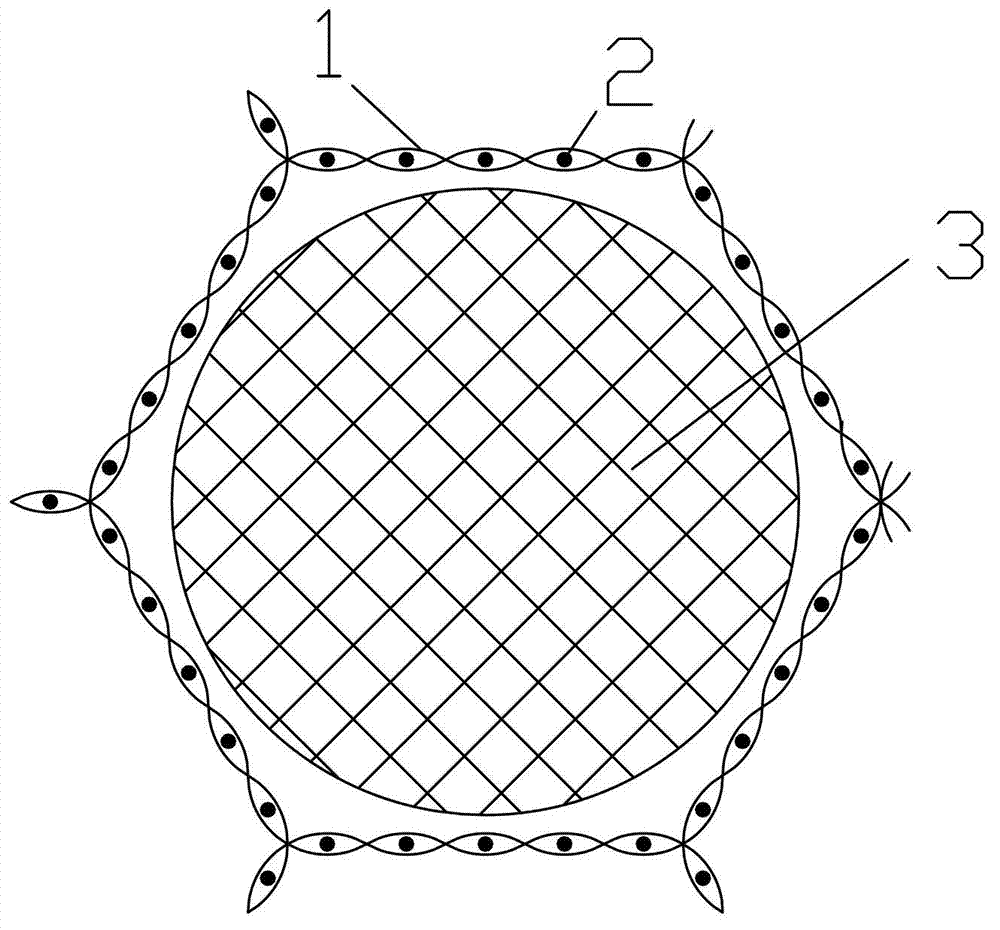

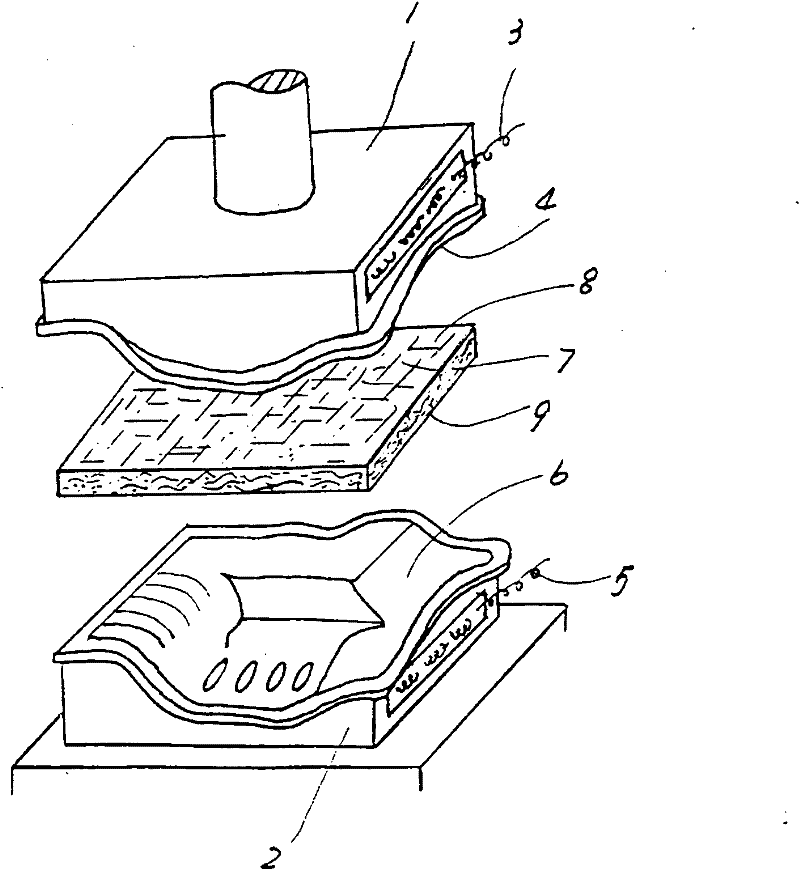

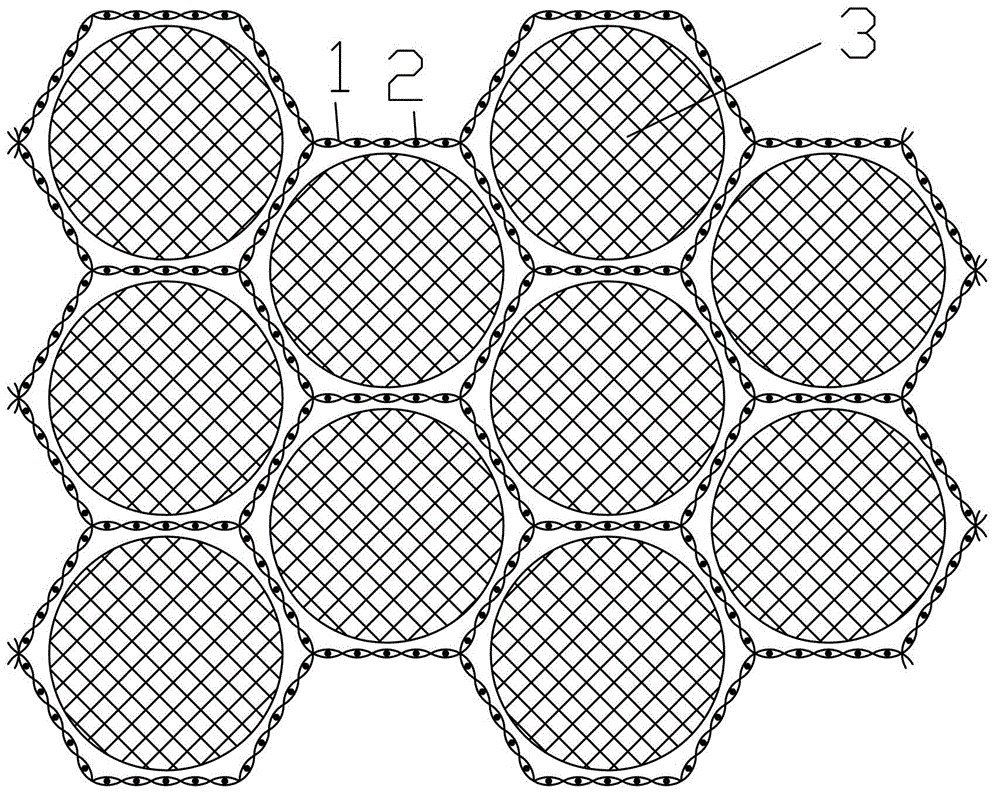

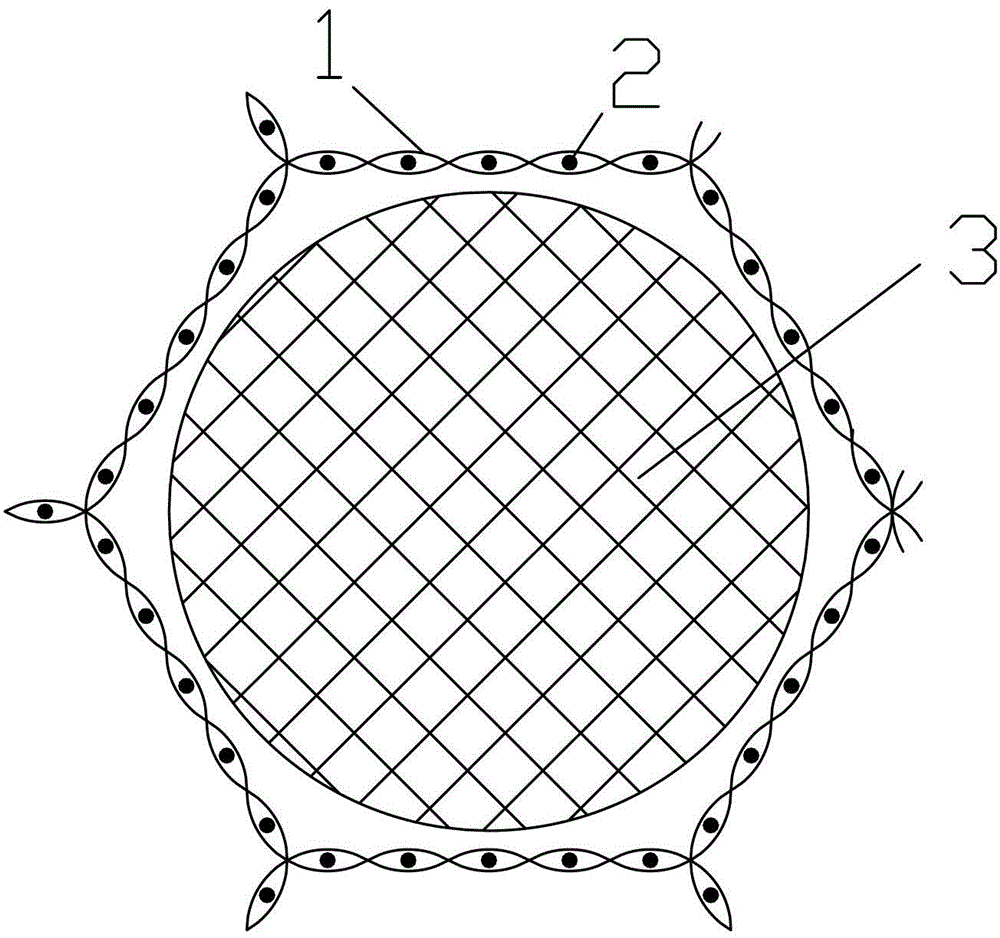

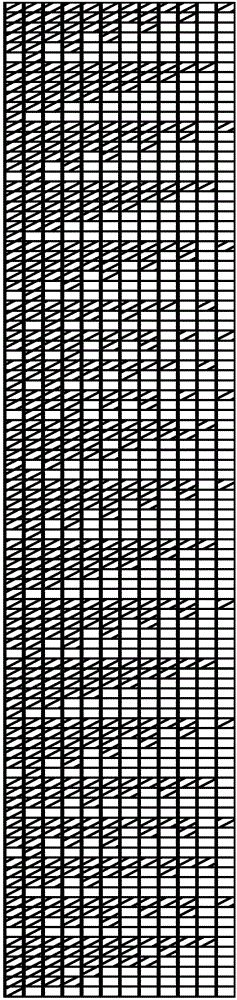

Three-dimensional woven fabric coated with multiple layers of emulsion strips

InactiveCN103074724AIncrease the number of layersIncreasing the thicknessWoven fabricsEmulsionWater vapor permeability

The invention discloses a three-dimensional woven fabric coated with multiple layers of emulsion strips. The three-dimensional woven fabric coated with the multiple layers of emulsion strips comprises warps, wefts and the emulsion strips, wherein the three-dimensional woven fabric consists of a plurality of repetitive tubular woven fabric units, wherein every two adjacent tubular woven fabrics are provided with a section of shared woven fabric; the tubular woven fabric unit is formed by weaving the warps and the wefts; and the emulsion strips are coated in the tubular woven fabric units by virtue of weaving. The three-dimensional woven fabric disclosed by the invention has the advantages of good integrity, structure stability, easiness for thickening, higher strength, higher compression resistance and favorable air permeability and water vapor permeability.

Owner:CHANGZHOU TEXTILE GARMENT INST

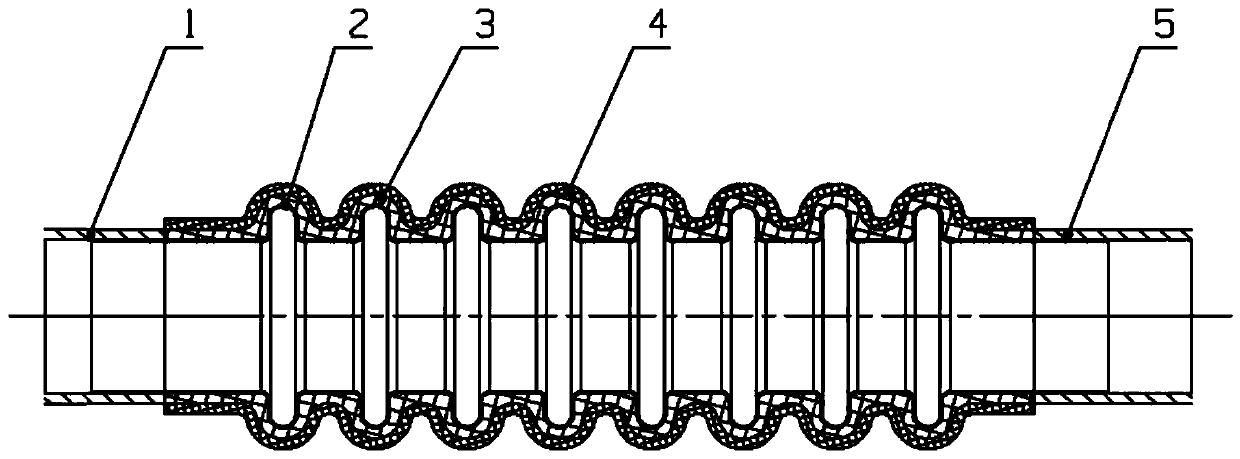

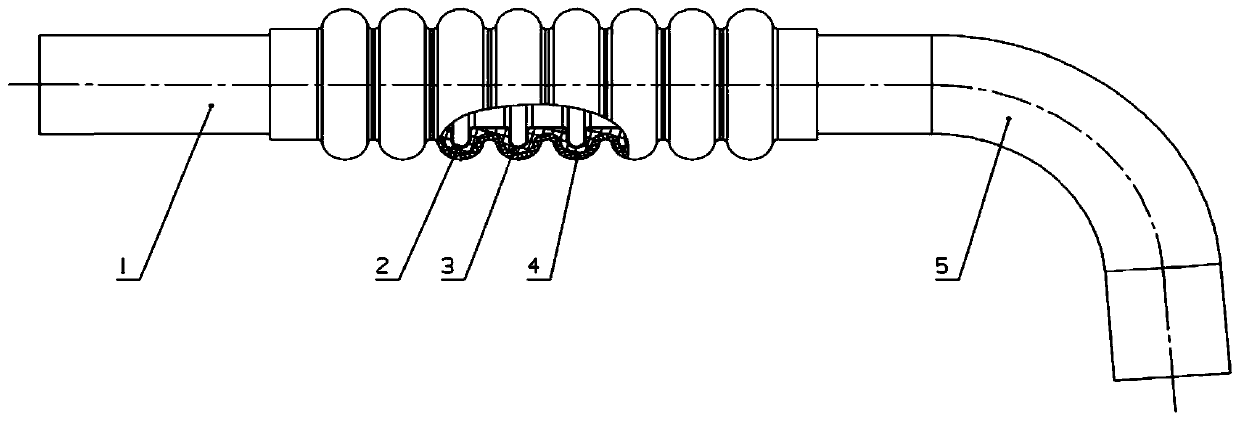

Complex structure corrugated pipe

PendingCN111473166ASolve the shortcomings of easy crackingReduce vibrationCorrosion preventionPipe protection against corrosion/incrustationCompound structureMechanical engineering

The invention discloses a complex structure corrugated pipe. The complex structure corrugated pipe comprises a metal corrugated pipe, a rubber inner layer and a rubber outer layer, wherein the metal corrugated pipe is formed by machining corrugations on a thin-wall steel pipe; the rubber inner layer is wrapped on the outer wall of the metal corrugated pipe; and the rubber outer layer is wrapped onthe outer wall of the rubber inner layer. The rubber layers of the complex structure corrugated pipe are closely combined with the corrugated pipe. Damping is high. Vibration of the corrugated pipe is reduced. Vibration parameters of the corrugated pipe are reduced. The anti-fatigue-cracking service life of the corrugated pipe is prolonged. The defect that the corrugated pipe cracks easily is overcome. Besides, when having cracks, the complex structure corrugated pipe can continuously achieve the normal delivery function with the aid of the sealing effect of the rubber layers and the secondary protective effect, prevent serious secondary faults that leakage of the substances such as oil, air and water delivered in the corrugated pipe causes fires, the performance is reduced and machines and equipment cannot operate, gain time for subsequent use and maintenance and minimize the fault influence.

Owner:广西玉柴船电动力有限公司

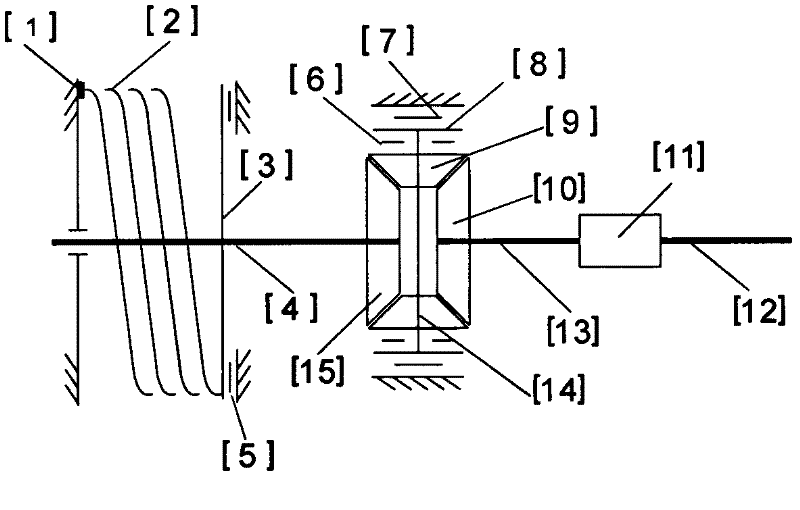

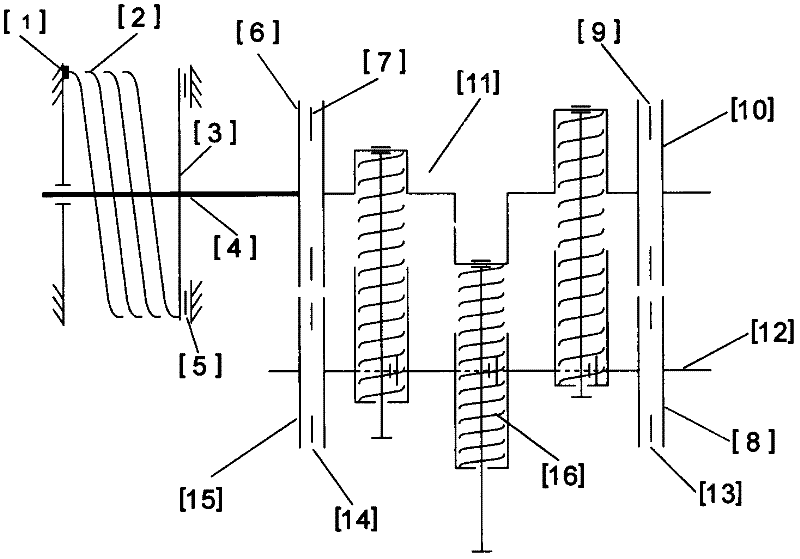

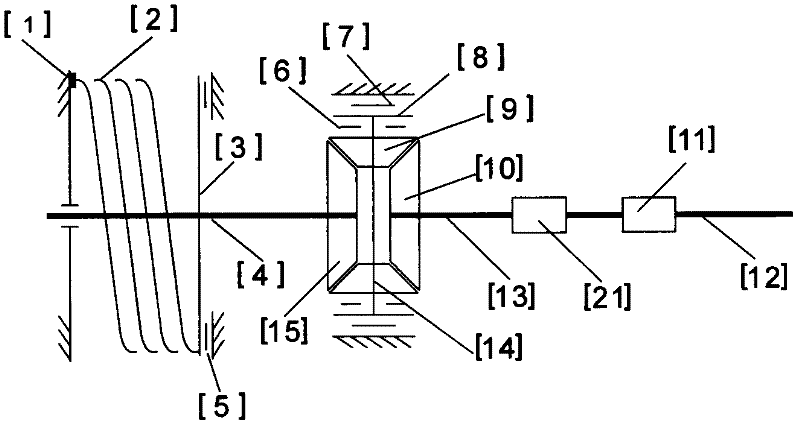

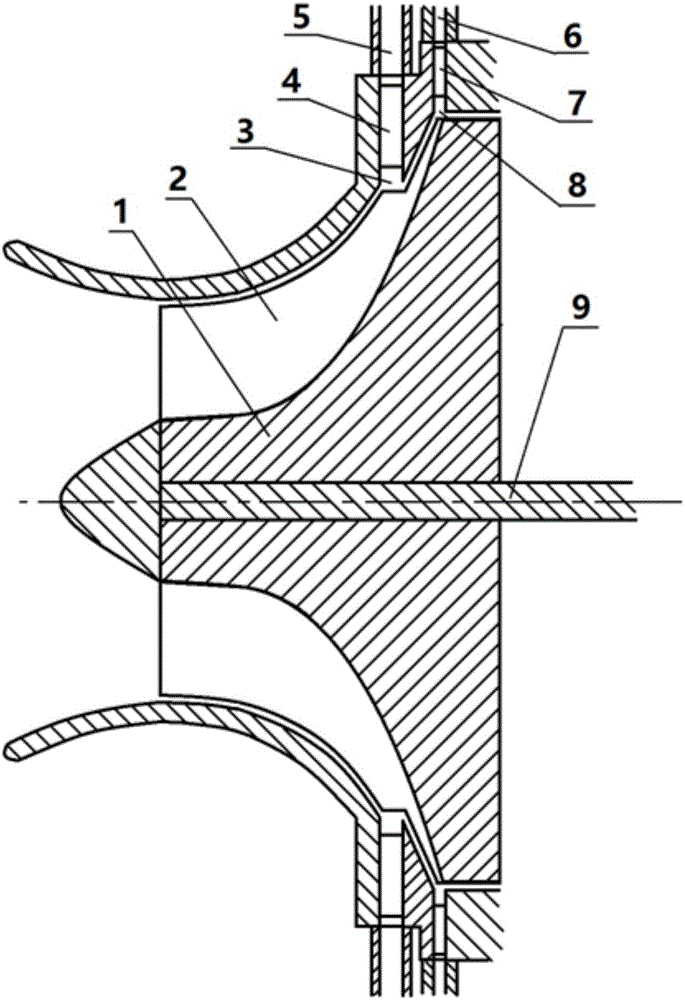

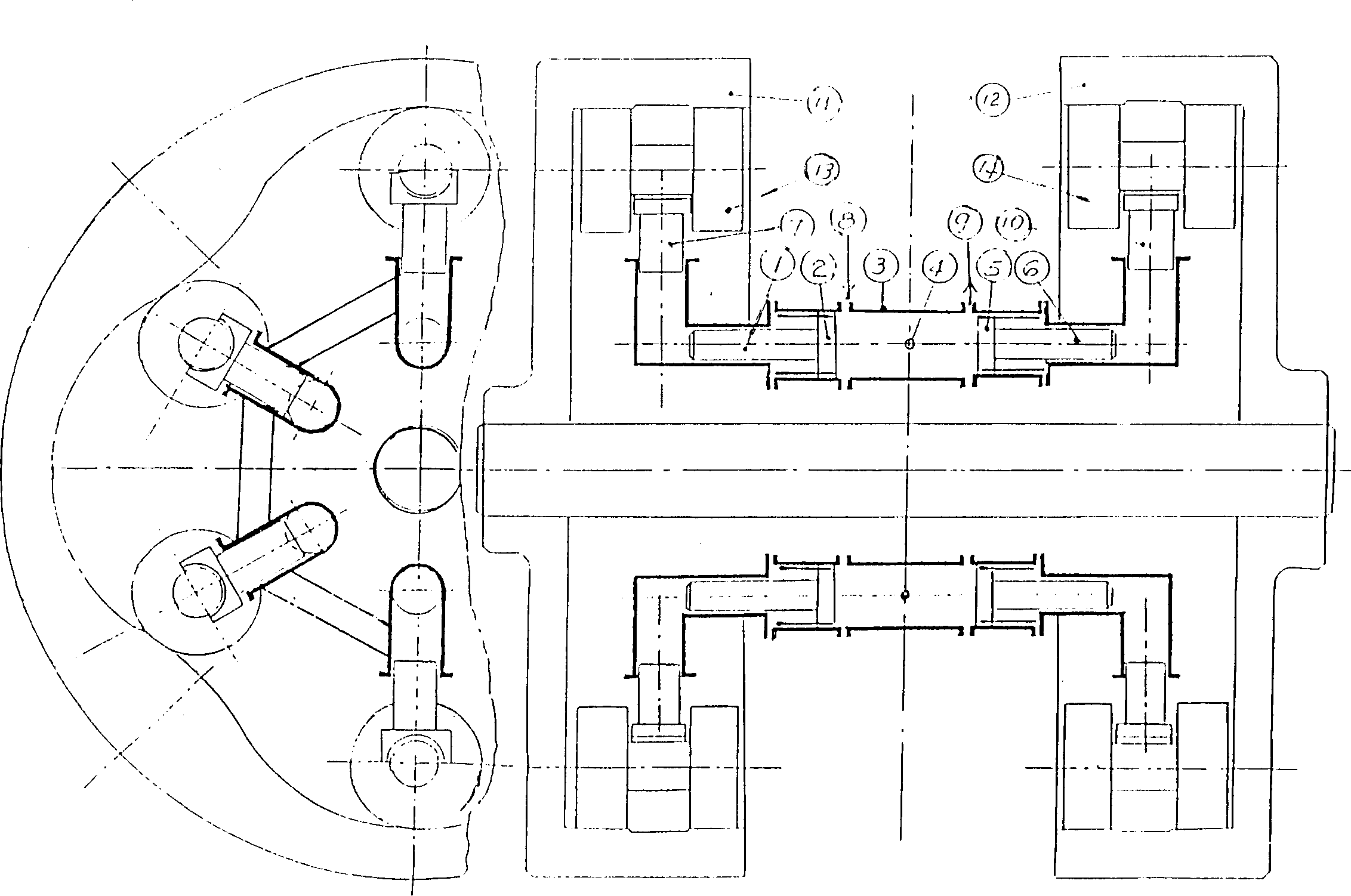

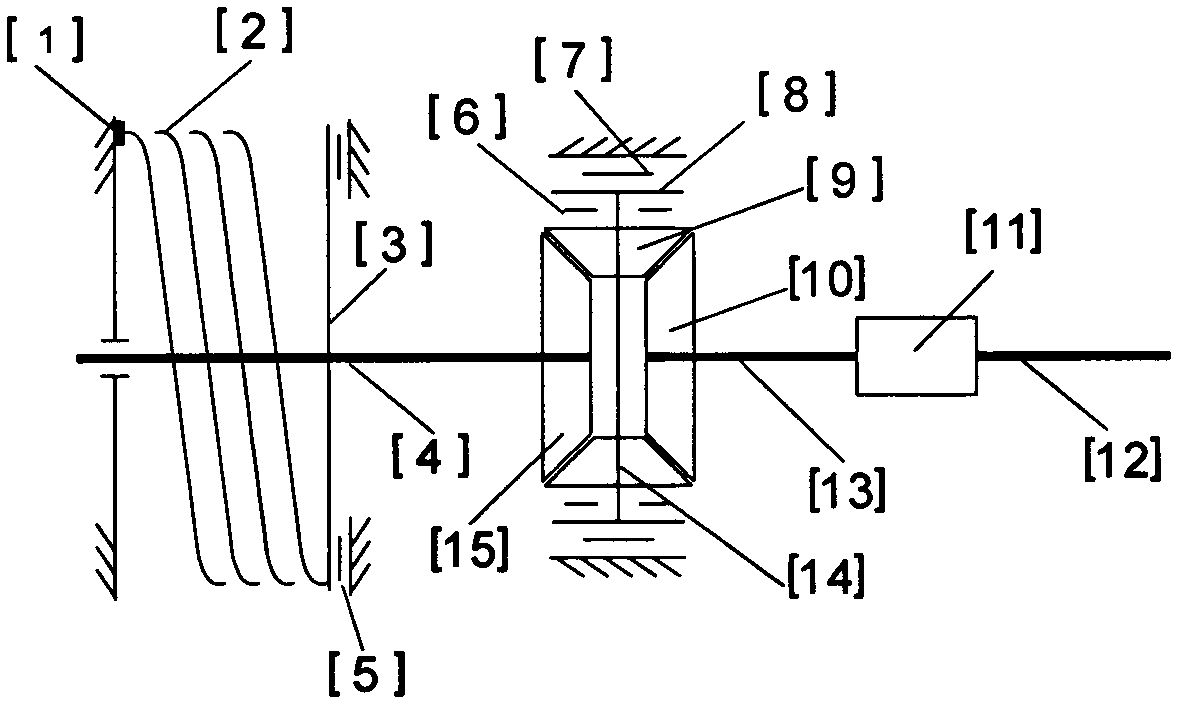

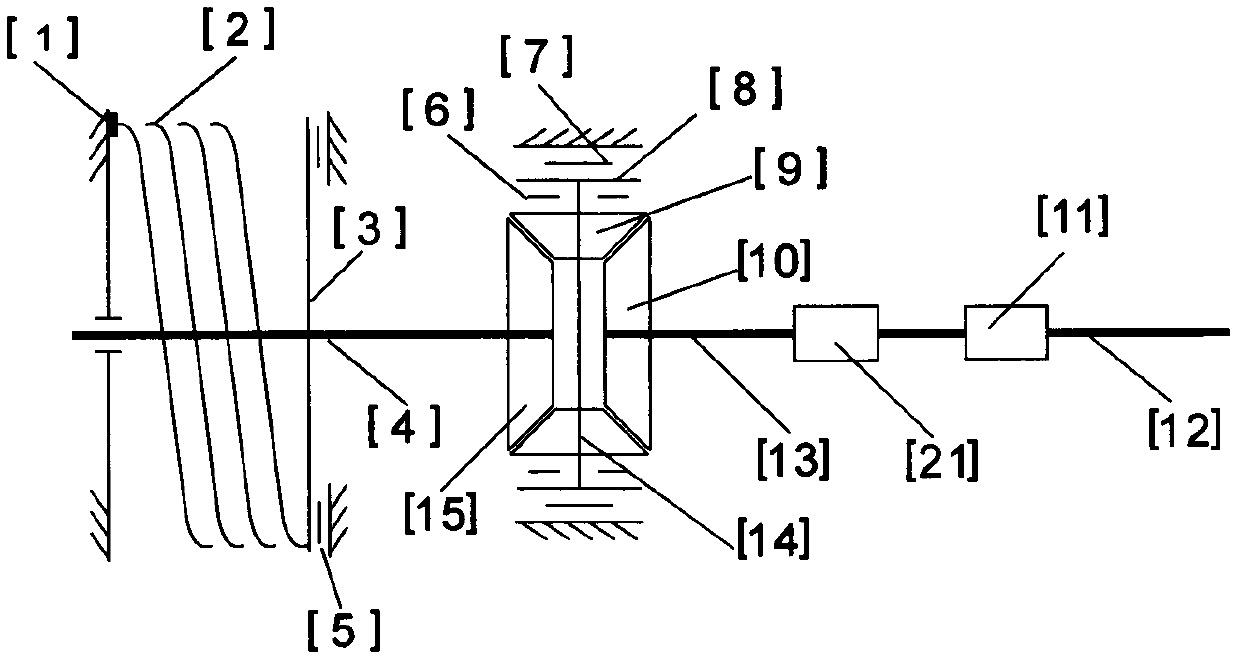

Centrifugal compressor with double pressure ratios

InactiveCN106837860AMeet the needs of different purposesLarge displacementPump componentsPumpsSingle stageEngineering

The invention belongs to the field of compressors, and relates to a dual-pressure-ratio centrifugal compressor, which includes a rotor and a stator. The rotor consists of a main shaft and an impeller sleeved on the main shaft. Annular outlets with different radii, among them, the annular outlet with large radius is located at the end of the impeller blade, which is a high-pressure outlet, and the annular outlet with a small radius is located at a certain position from the top to the end of the impeller blade, which is a low-pressure outlet. The diffuser is connected with the low-pressure diffuser, and the high-pressure diffuser and the low-pressure diffuser are respectively connected with the high-pressure air collecting pipe and the low-pressure air collecting pipe. The invention adopts the design concept of setting two air outlets on one impeller, so that the single-stage centrifugal compressor can output two kinds of gases with different pressure ratios to meet the needs of different purposes. The effect of the double ducting of the engine.

Owner:SHENZHEN FUSTAR POWER TECH CO LTD

Method of preparing polyaluminocarbosilane

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

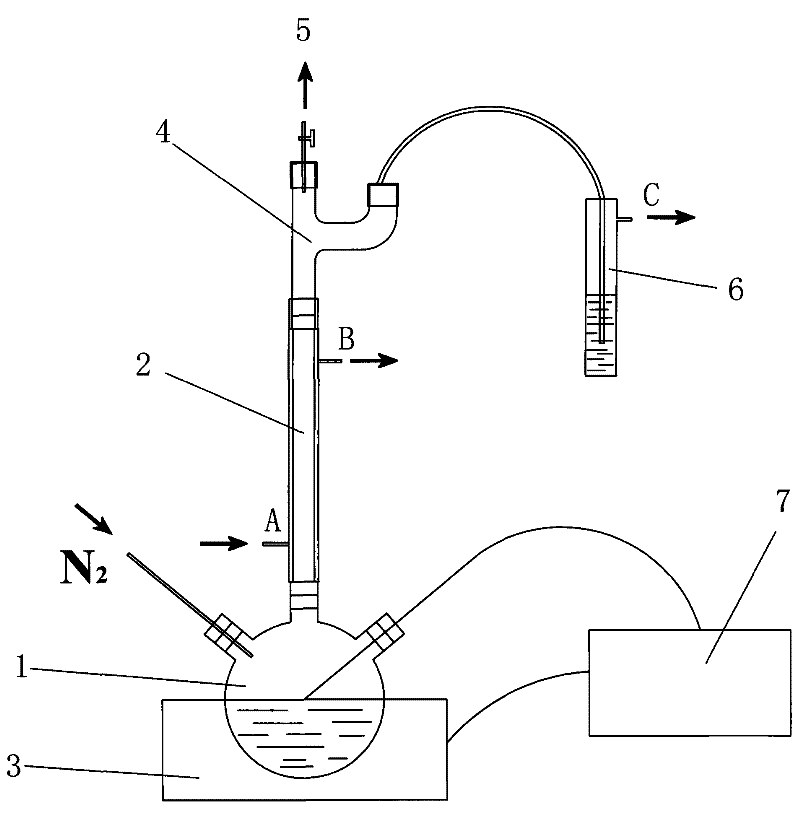

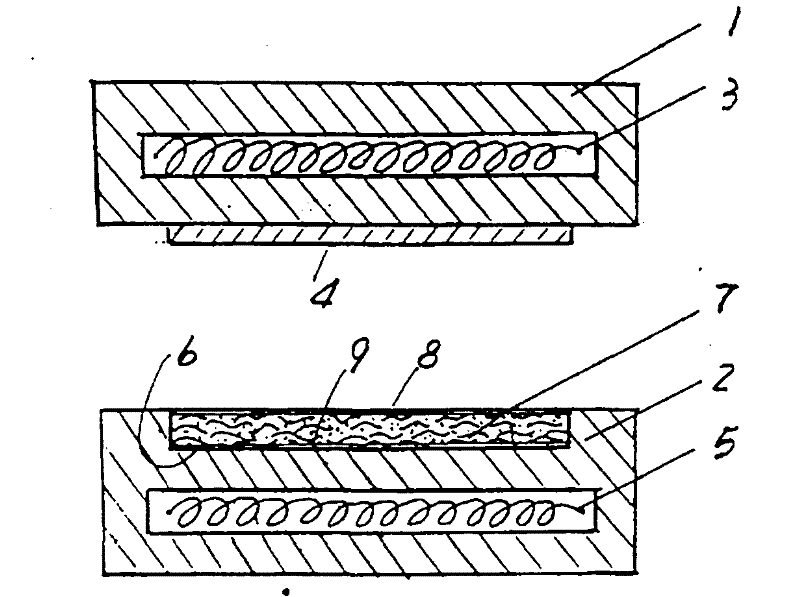

Process for preparing ultra-thin, high-density glass wool products

InactiveCN102294872ARealize preparation and productionMeet the needs of different purposesLaminationLamination apparatusHigh densityBuilding integration

The invention relates to a heat-collecting and heat-preserving glass wool roll, which includes heat-preserving glass wool. The upper surface and the lower surface of the heat-preserving glass wool are respectively provided with aluminum foil paper and heat-collecting paper. Bonding, in which the insulating glass wool is a single layer or a combination of multiple layers. The beneficial effects of the present invention are: the thermal insulation glass wool roll can be installed and applied on various buildings for thermal insulation and heat collection, and it is convenient, beautiful, firm and low-cost to form an integral body with the building to play the role of building thermal insulation and heat collection. It also facilitates the integration of solar energy and buildings.

Owner:NANTONG HAIJIA COMPOUND MATERIAL CO LTD

A method for preparing quartz needles by etching capillaries with hydrofluoric acid

ActiveCN106486336BSimple and fast operationReduce usageSamples introduction/extractionMaterial analysis by electric/magnetic meansHydrofluoric acidPolymer coatings

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Three-dimensional woven fabric coated with multiple layers of emulsion strips

InactiveCN103074724BIncrease elasticityImprove breathabilityWoven fabricsEmulsionWater vapor permeability

The invention discloses a three-dimensional woven fabric coated with multiple layers of emulsion strips. The three-dimensional woven fabric coated with the multiple layers of emulsion strips comprises warps, wefts and the emulsion strips, wherein the three-dimensional woven fabric consists of a plurality of repetitive tubular woven fabric units, wherein every two adjacent tubular woven fabrics are provided with a section of shared woven fabric; the tubular woven fabric unit is formed by weaving the warps and the wefts; and the emulsion strips are coated in the tubular woven fabric units by virtue of weaving. The three-dimensional woven fabric disclosed by the invention has the advantages of good integrity, structure stability, easiness for thickening, higher strength, higher compression resistance and favorable air permeability and water vapor permeability.

Owner:CHANGZHOU TEXTILE GARMENT INST

Processing method of shale oil

InactiveCN102079990BReduce viscosityImprove plasticityTreatment with plural serial refining stagesHydrocarbon oils refiningEconomic benefitsAtmospheric pressure

The invention discloses a processing method of shale oil, which comprises the following steps: after mixing shale oil and an extracting agent, heating up, and starting to stir so that the shale oil and the extracting agent are thoroughly mixed and are thoroughly in contact with each other; stopping stirring, standing so that the extract phase and the raffinate phase stratify, and separating the extract phase and the raffinate phase; and respectively distilling the extract phase and the raffinate phase to respectively obtain extract oil and the extracting agent, and raffinate oil and the extracting agent, and recovering the extracting agent. The method disclosed by the invention is simple and easy to operate, and the reaction conditions are mild; and the method can be carried out under theconditions of atmospheric pressure and low temperature, does not need the participation of the catalyst, and thus, has the advantages of low input cost and obvious economic benefit. Meanwhile, the method can be used for generating multiple products, such as extract oil composed of light and heavy components respectively for preparing non-hydrocarbon compounds and asphalt products, and raffinate oil which can be directly used as the raw material for catalytic cracking, thereby increasing the added value of the products. The heavy component of the extract oil has the advantages of low viscosity, high plasticity and high temperature sensibility, and can be blended into asphalt of different designations to satisfy the demands for different purposes.

Owner:抚顺欧力石化有限公司

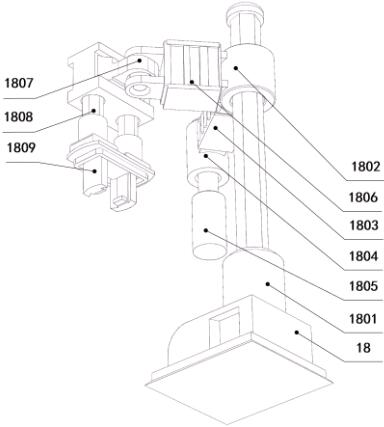

A kind of manufacturing equipment of composite ceramic target

ActiveCN109231997BReal-time control of product qualityHigh product levelPhase mixingComposite ceramic

Owner:房孝兰

A scaffold-type silk fibroin film that is insoluble in water and its preparation and application

The invention discloses a stent type silk fibroin film insoluble in water, and preparation and application of the stent type silk fibroin film. A preparation method includes the steps of placing silk fibroin solution in a smooth, flat and horizontal mold, and obtaining a basilar film by humid and heat crosslinking; and laying the silk fibroin solution on the surface of the basilar film and forming the stent type silk fibroin film insoluble in water after freezing, drying and humid and heat crosslinking. Silk fibroin is used as a raw material, and biocompatibility is good; a preparation process is non-toxic and environment-friendly, and the thickness of the film and the aperture of a stent layer are easy to control; the film is soft in a moist environment, the basilar film is compact, and cells, microorganisms and biomacromolecules cannot penetrate through the basilar film; the stent layer is in the shape of a porous sponge, and is beneficial to fixation of the film, hemostasis of a wound and regeneration of transmitting tissues; and the film has a wide market in the field of anti-adhesive films and artificial film patches.

Owner:ZHEJIANG XINGYUE BIOTECH

A kind of preparation method of cross-linked aliphatic polycarbonate

Owner:NORTHWEST NORMAL UNIVERSITY

A method and post-treatment process for preparing high-temperature nickel-based alloy porous materials by 3dp method

ActiveCN109807320BMeet the needs of different purposesLow costAdditive manufacturing apparatusPore distributionAlloy

The invention discloses a method and a post-treatment process for preparing high-temperature nickel-based alloy porous materials by a 3DP method. Mixing; B. Macroscopic direct pore creation: According to the shape characteristics, porosity, pore distribution law and pore shape and size design requirements of porous materials, a three-dimensional model of porous structure is designed through three-dimensional design software; C. 3DP method to prepare porous materials: 3DP The equipment receives the printing program, sets the printing parameters and starts printing; D. Removal of residual powder: first take out the rough powder from the powder pile, and then remove the residual powder on the rough base; E. Debonding and atmosphere sintering treatment: send the rough base to Go to the muffle furnace for debonding and atmosphere sintering; F, electrochemical corrosion: perform electrochemical corrosion treatment on the sintered nickel-based porous material; G, cryogenic treatment: put the workpiece into a cryogenic device for cryogenic treatment; H, The preparation and post-treatment of the high-temperature nickel-based alloy porous material are completed.

Owner:NANTONG INST OF TECH

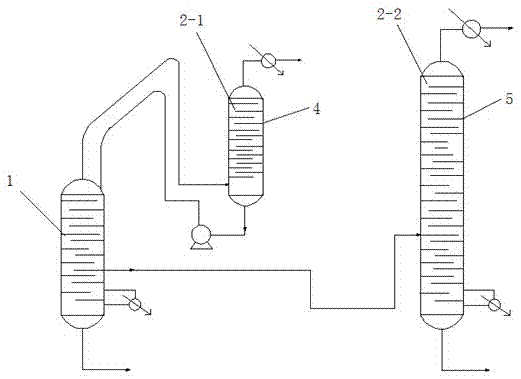

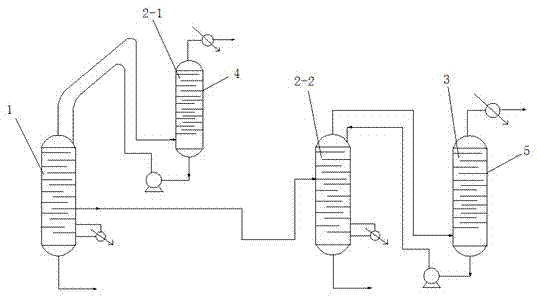

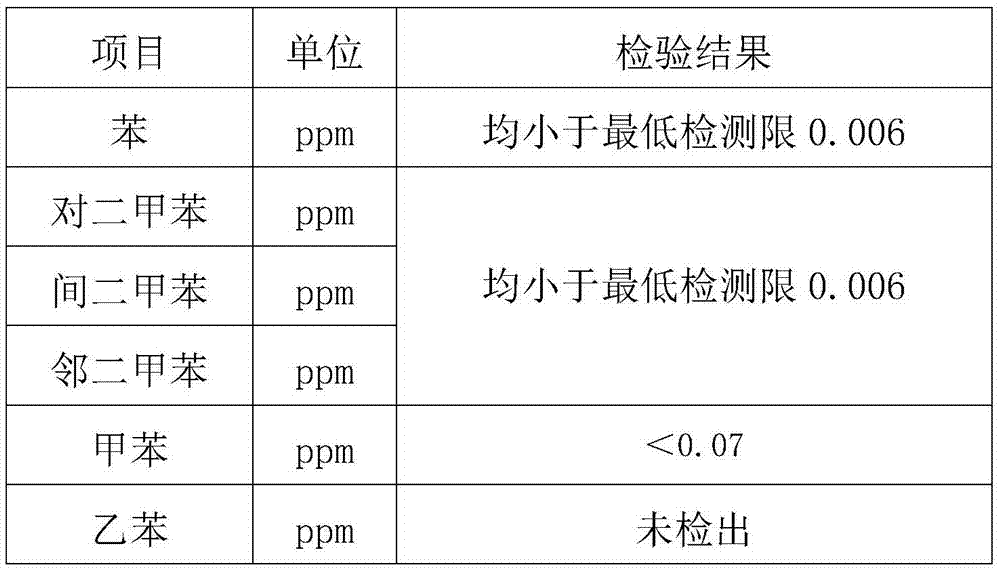

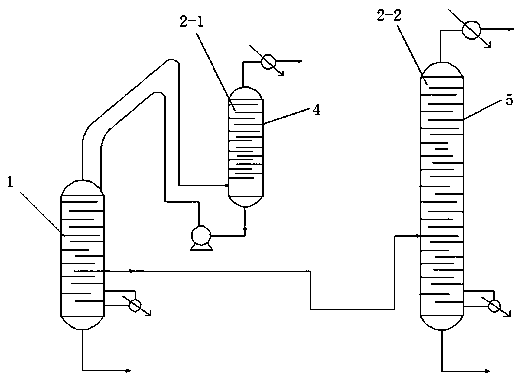

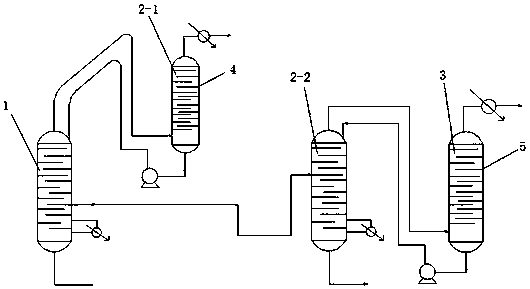

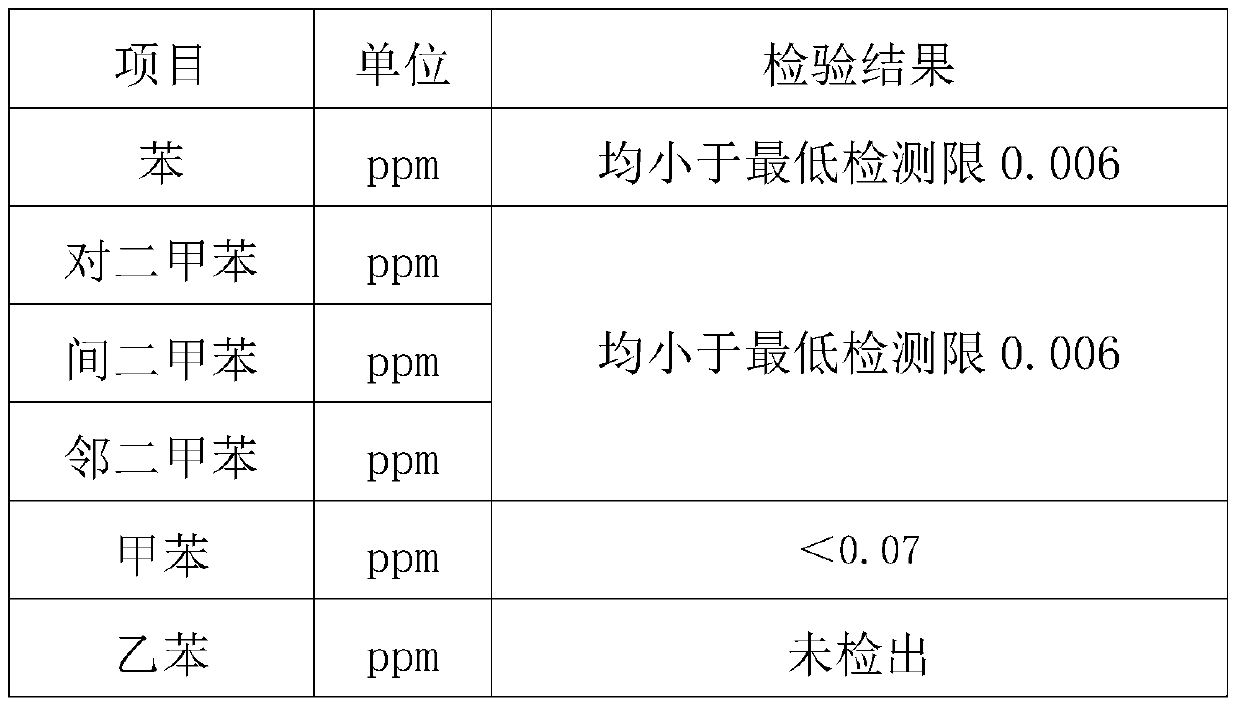

Rectifying device and method of vinyl acetate

ActiveCN106905156ALow content of benzene and benzene seriesSolve the problem of high content of benzene and benzene seriesOrganic compound preparationCarboxylic acid esters preparationBenzeneLatex rubber

The invention relates to a rectifying method of vinyl acetate. The rectifying method comprises the following steps of firstly, using a rectifying tower to rectify the degassed and crudely distilled vinyl acetate; then, respectively rectifying the vinyl acetate in a rectifying section and a stripping section of the rectifying tower. The rectifying method has the advantages that by rectifying the vinyl acetate in the stripping section, the contents of benzene and benzene series in the vinyl acetate are greatly reduced; the problem of high contents of the benzene and the benzene series in the vinyl acetate in the prior art is solved, and the quality standard of smoke water-based latex products is met.

Owner:SINOPEC SICHUAN VINYLON FACTORY +1

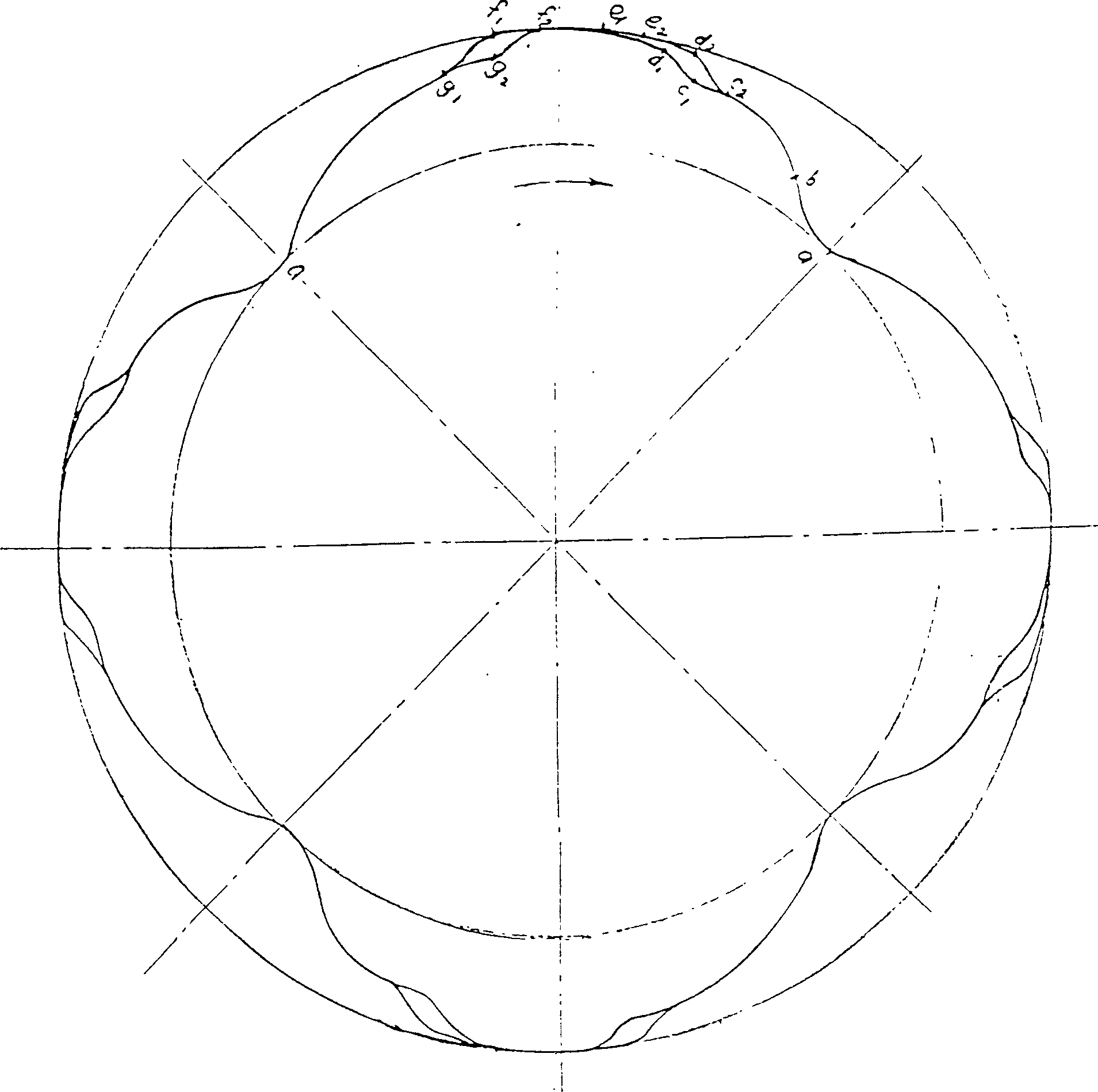

Hydraulic drive internal combustion engine

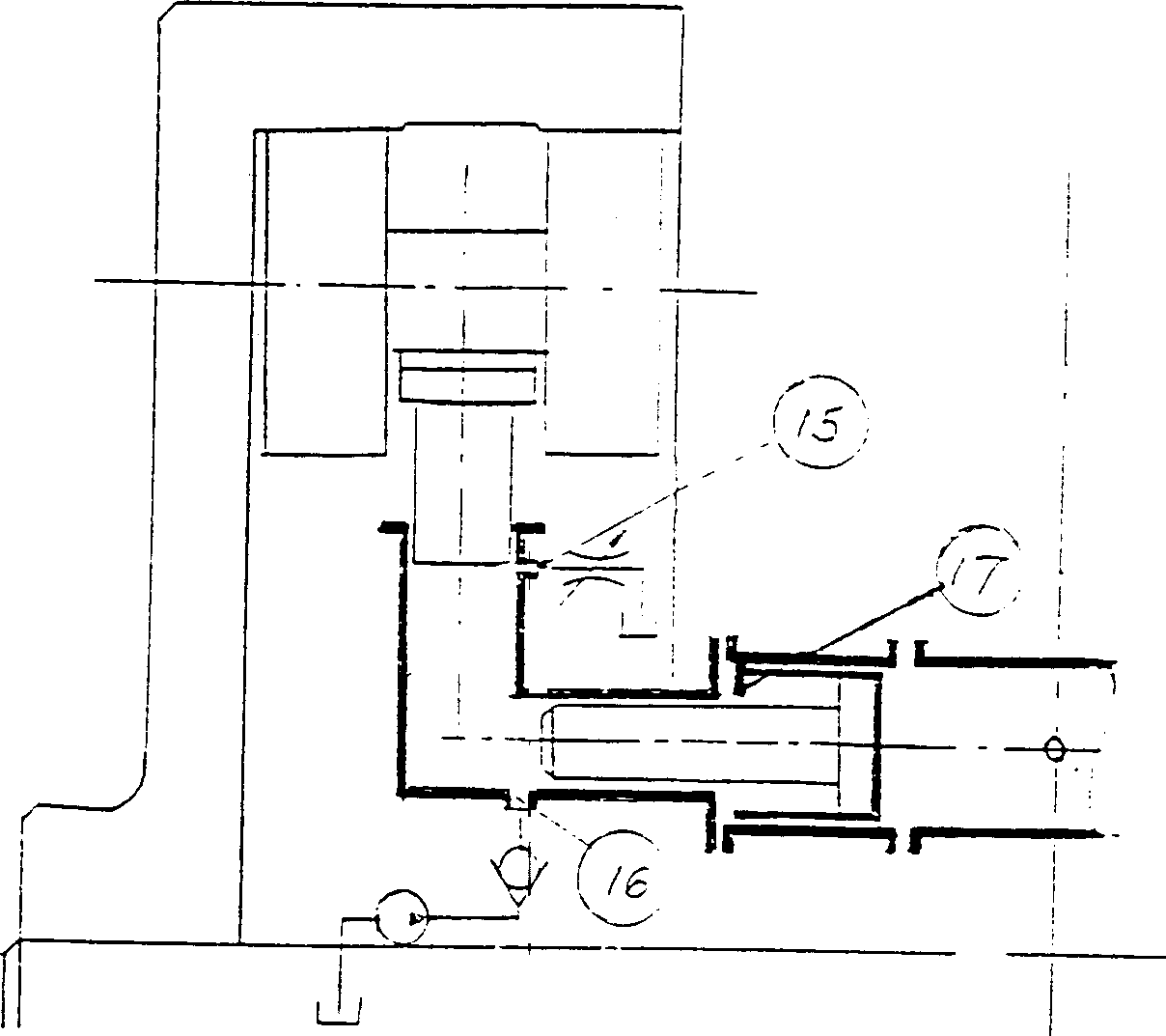

InactiveCN1103408CNo vibrationReduce noiseMachines/enginesHydraulic cylinderInternal combustion engine

A new-type IC engine with hydraulic drive other than crank-connecting rod mechanism is composed of opposed piston cylinders, plunger pumps at both ends, and plunger-type internal or external curved oil motor unit. The cam curve can control and optimize the speed distribution of opposed pistons. Said hydraulic cylinder has liquid supplementing, cooling and liquid replacing mechanisms.

Owner:赵硕颀

Water-soluble polyvinyl alcohol fibre and preparation technique thereof

InactiveCN101177800BReduce energy consumptionOptimize and shorten the production processArtificial filament heat treatmentWet spinning methodsFiberPolymer science

The invention relates to a water-soluble polyvinyl alcohol fiber and a preparation method thereof. The water-soluble polyvinyl alcohol fibers provided by the invention has the following natural parameters: the dry breaking strength of fibers is more than or equal to 5cN / dtex; dry breaking elongation rate is 10 percent to 20 percent; water solution temperature is 60 DEG C to 90 DEG C; single fibertiter is 1.0dtex to 8dtex; the number of crimp is 8 to 12 / 25mm. The invention conquers the imperfections of the existing method of long technique procedure and high production energy consumption caused by the redrying of fibers, furthermore, the property of the prepared water-soluble polyvinyl alcohol fibers is improved to some extent.

Owner:HUNAN XIANGWEI

A kind of rectification device and method of vinyl acetate

ActiveCN106905156BLow content of benzene and benzene seriesSolve the problem of high content of benzene and benzene seriesOrganic compound preparationCarboxylic acid esters preparationBenzeneLatex rubber

The invention relates to a rectifying method of vinyl acetate. The rectifying method comprises the following steps of firstly, using a rectifying tower to rectify the degassed and crudely distilled vinyl acetate; then, respectively rectifying the vinyl acetate in a rectifying section and a stripping section of the rectifying tower. The rectifying method has the advantages that by rectifying the vinyl acetate in the stripping section, the contents of benzene and benzene series in the vinyl acetate are greatly reduced; the problem of high contents of the benzene and the benzene series in the vinyl acetate in the prior art is solved, and the quality standard of smoke water-based latex products is met.

Owner:SINOPEC SICHUAN VINYLON FACTORY +1

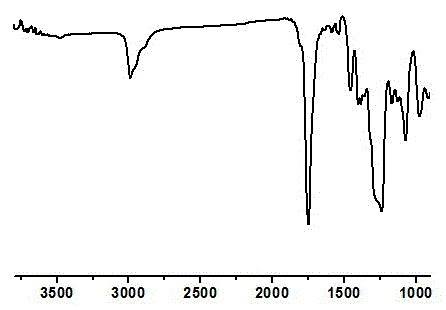

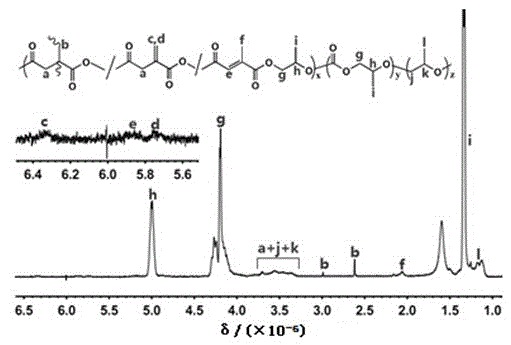

Organosilane crosslinked polyolefin elastic-body composition

The invention is silicon alkyl cross-linking polyolefin elastomer combination, adopting LLDPE (or ULDPE) and paraffin ot replace EPDM and using silicon grafting system to replace bakelite sulfuration system. It can meet different demands. The components of the compound: PP 2-10 phr; LDPE or ULDPE 50-80 phr; paraffin 50-500 phr; silicon hydride 2-10 phr; peroxide 0.5-2.5 phr; water 0.1-5.0 phr; and anti-oxidizing agent: 0.1-0.3%.

Owner:SINOPEC YANGZI PETROCHEM

Face shaped exothermic material with electric bamboo as packing material and preparation method

InactiveCN100452930CEasy to passEase of evacuationHeating element materialsFace shapeThermal efficiency

Technical scheme is as following: exothermic material is composed of granules of bamboo charcoal and organic or inorganic bond; granules of bamboo charcoal is as conducting medium in 10-70 wt % of exothermic material, and organic or inorganic bond is as base body in residual amount. Advantages are: whole surface is heating surface and heat delivery surface so as not form local high temperature; small current density is for safe use; high thermal efficiency possesses features of energy saving; the exothermic material can be prepared in different shape.

Owner:ZHEJIANG FORESTRY UNIVERSITY

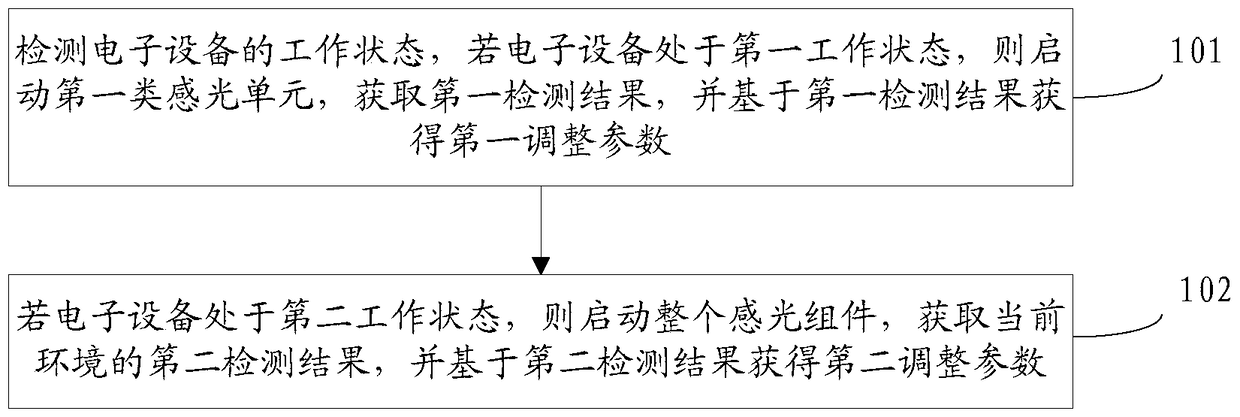

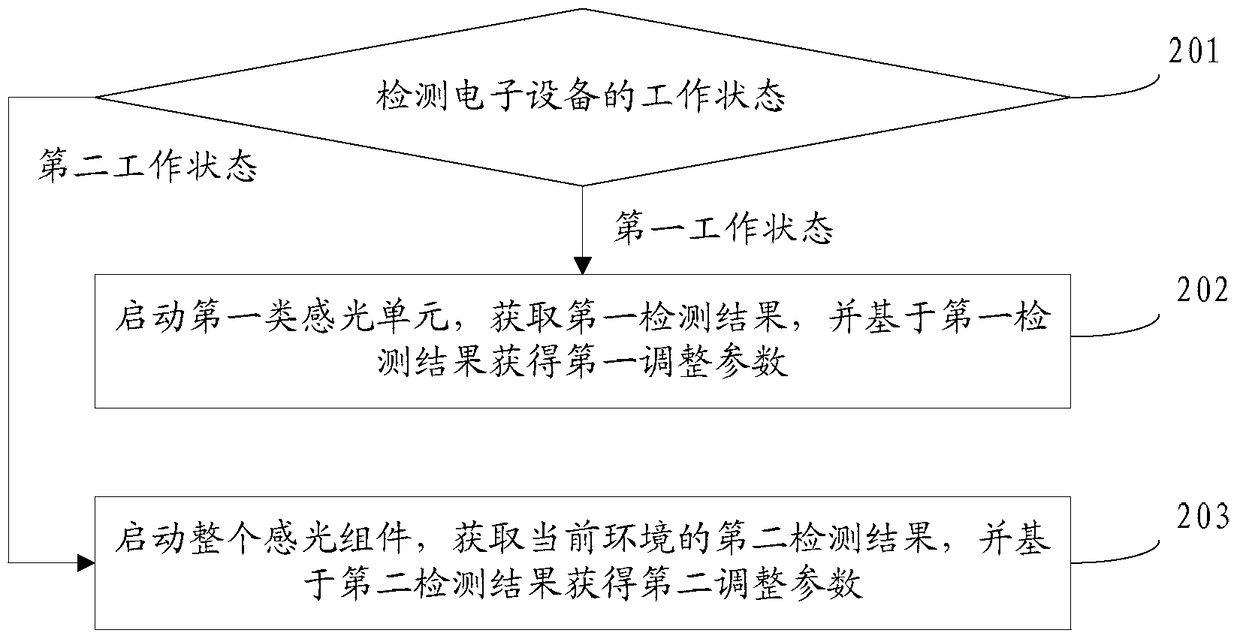

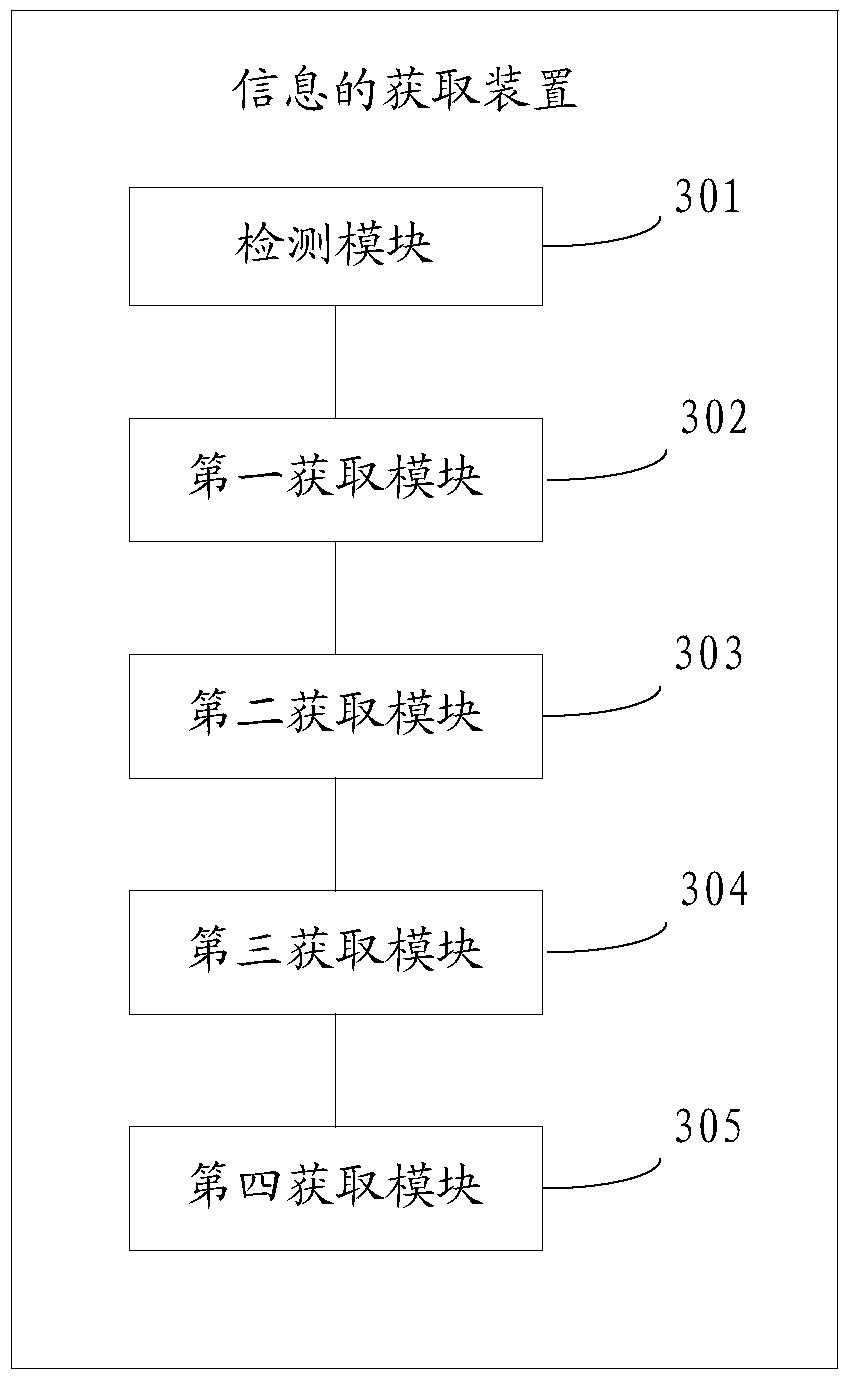

An information acquisition method and electronic device

ActiveCN104951356BIncrease profitMeet the needs of different purposesMultiprogramming arrangementsOptical sensingComputer science

The invention discloses an information acquiring method and electronic equipment and belongs to the optical sensing technical field. The method comprises the steps of detecting the working state of the electronic equipment, starting a first kind of photosensitive units if the electronic equipment is in the first working state, acquiring a first detection result, and acquiring a first adjustment parameter based on the first detection result; starting the whole photosensitive component if the electronic equipment is in the second working state, acquiring a second detection result of the current environment, and acquiring a second adjustment parameter based on the second detection result. According to the method, the photosensitive component is arranged and is totally started when the electronic equipment is in the second working state, and the first kind of photosensitive units in the photosensitive component is started when the electronic equipment is in the first working state; in this way, only one photosensitive component can meet the requirement for different purposes, another photosensitive component does not need to be arranged to be used when the electronic equipment is in the first working state, and then the utilization rate of the photosensitive component is quite high.

Owner:LENOVO (BEIJING) LTD

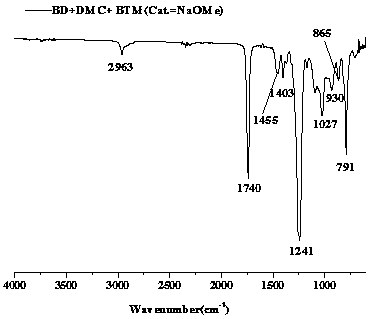

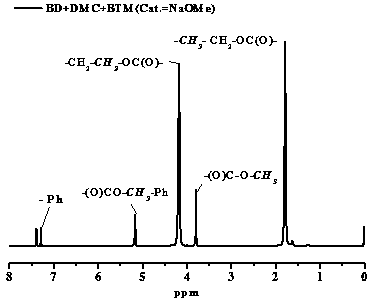

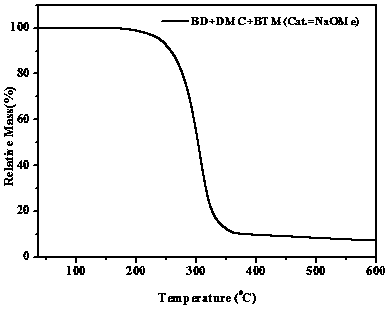

A method for cross-linking modification of aliphatic polycarbonate

A method for cross-linking modification of aliphatic polycarbonate, including the following steps: using aliphatic diol and dimethyl carbonate DMC as polymerization monomers under the action of a catalyst, introducing a cross-linking agent 1,3,5-benzene Trimethanol BTM is obtained through one-pot polymerization; the cross-linked aliphatic carbonate prepared by the invention has good thermal properties and swelling properties, and has good application prospects in the field of environmental pollution treatment; the cross-linking process in the polymerization reaction is changed The addition amount and polymerization conditions of the agent 1,3,5-benzenetrimethanol can effectively control the cross-linking degree and performance of aliphatic polycarbonate to meet the needs of different uses.

Owner:NORTHWEST UNIV

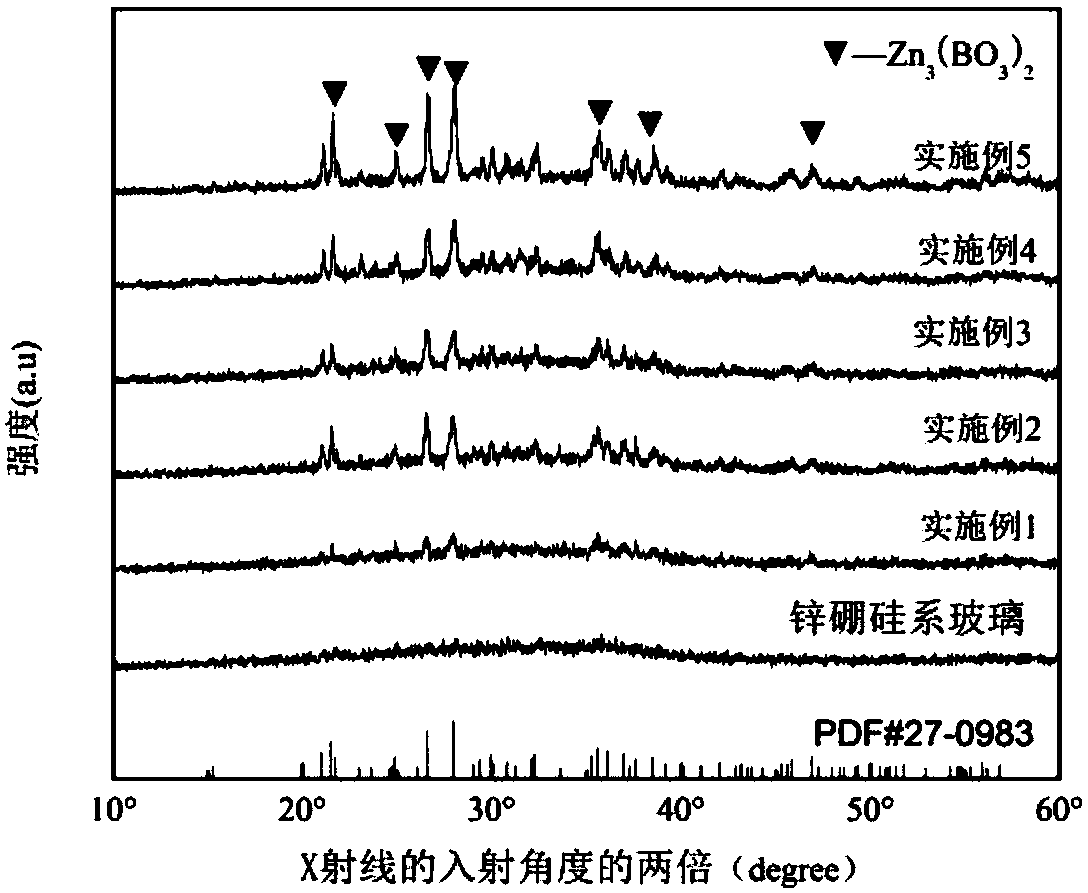

Preparation method of surface devitrified glass-ceramics

The invention relates to the technical field of glass, in particular to a method for preparing surface crystallization glass ceramics. The method comprises the steps of 1, providing raw materials and grinding and evenly mixing the raw materials, wherein the raw materials are zinc oxide, boron oxide and silicon dioxide which are mixed based on the molar ratio of (25-60):(5-50):(5-30); 2, heating and melting the product generated in step 1 to obtain glass metal; 3, conducting molding and annealing on the glass metal generated in step 2 to obtain an intermediate product; 4, conducting heat treatment on the intermediate product generated in step 3 to obtain the surface crystallization glass ceramics. According to the method, no crystallization agent is required, processes are simple, steps are clear, cost is low, and surface crystallization effect is good.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Controllable Elastic Energy Release and Recovery System

The invention discloses a controllable elastic energy release and recovery system, which uses a certain number of coil springs (or other elements or components capable of elastic deformation) as the energy storage mechanism of the system, and is equipped with a suitable speed changer (and changer) to the mechanism) and other auxiliary devices. Under the control of the control system, through the variable speed and torque of the transmission and the reversing of the reversing mechanism, the coil spring can not only store the recyclable energy, but also release the stored energy as needed to complete the energy release and recovery. task; and while maintaining a high speed at the output end of the coil spring, it can not only make the two ends of the coil spring rotate in the same direction at different speeds, reduce the energy release or recovery speed of the coil spring, but also make the coil spring The two ends of the coil rotate in reverse to increase the energy release or recovery speed of the coil spring, so that the system can operate normally within a large range of torque of the coil spring, better complete the energy release and recovery tasks, and improve the energy efficiency. utilization rate.

Owner:怀化沃普环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com