A scaffold-type silk fibroin film that is insoluble in water and its preparation and application

一种丝素蛋白、支架型的技术,应用在医药科学、吸收垫、假体等方向,能够解决多孔支架孔壁厚度不均一、丝素蛋白支架力学高、降解速率缓慢等问题,达到利于大量生产、制备工艺简单、减少异物感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

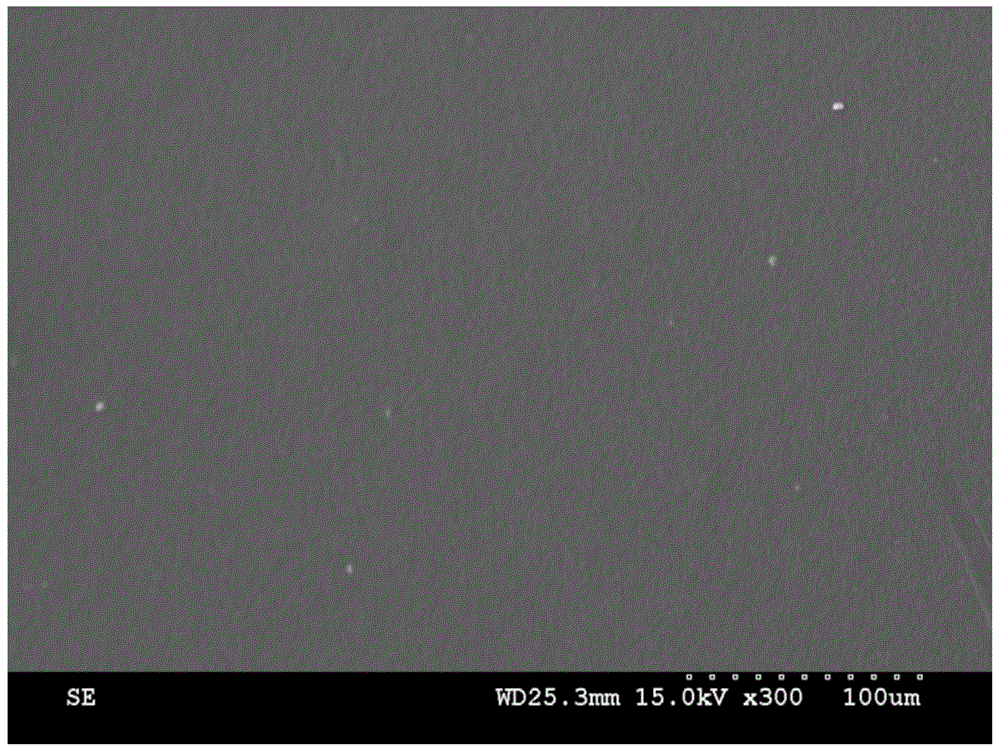

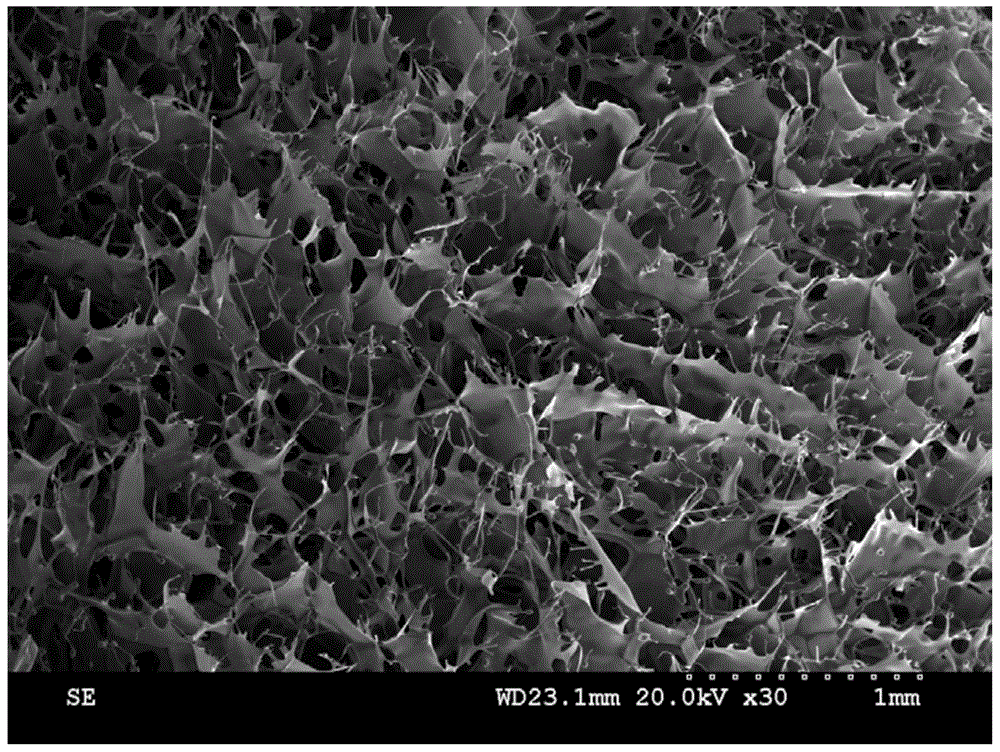

[0029] Example 1 (basement membrane 300 μm, scaffold layer 4000 μm)

[0030] (1) Preparation of silk fibroin solution: a) Degumming: Put 100g of silkworm silk (Zhejiang Huazhi Silk Co., Ltd., 5A grade) into 5L of 2M sodium carbonate aqueous solution, bathe in 98°C for 30min, and wash with deionized water , this process was repeated 3 times, the sericin was removed, and the silk fibroin was left, and the silk fibroin was dried at 50°C to obtain 70g of dried silk fibroin for later use; b) dissolving: the above-mentioned dried silk The fibroin is dissolved in 9.3 M lithium bromide (LiBr) aqueous solution at a mass volume ratio of 0.2:1 (that is, 0.2 g of dried silk fibroin is added to each ml of lithium bromide aqueous solution), and the silk fibroin is fully dissolved in a 60°C water bath for 90 minutes to obtain A mixture containing silk fibroin and a small amount of insoluble particles; c) Dialysis: Dialyze the mixture with a regenerated cellulose dialysis bag (molecular weigh...

Embodiment 2

[0035] Example 2 (basement membrane 200 μm, scaffold layer 1000 μm)

[0036] (1) Preparation of silk fibroin solution: a) Degumming: Put 100g of silkworm silk (Zhejiang Huazhi Silk Co., Ltd., 5A grade) into 5L of 2M sodium carbonate aqueous solution, bathe in 98°C for 30min, and wash with deionized water , this process was repeated 3 times, the sericin was removed, and the silk fibroin was left, and the silk fibroin was dried at 50°C to obtain 70g of dried silk fibroin for later use; b) dissolving: the above-mentioned dried silk The fibroin is dissolved in 9.3M lithium bromide (LiBr) aqueous solution at a mass volume ratio of 0.2:1, and the silk fibroin is fully dissolved in a 60°C water bath for 90 minutes to obtain a mixed solution containing silk fibroin and a small amount of insoluble particles; c) Dialysis: The above mixed solution was dialyzed with a regenerated cellulose dialysis bag (molecular weight cut-off 8000 Daltons), dialyzed 12 times with sterile deionized water...

Embodiment 3

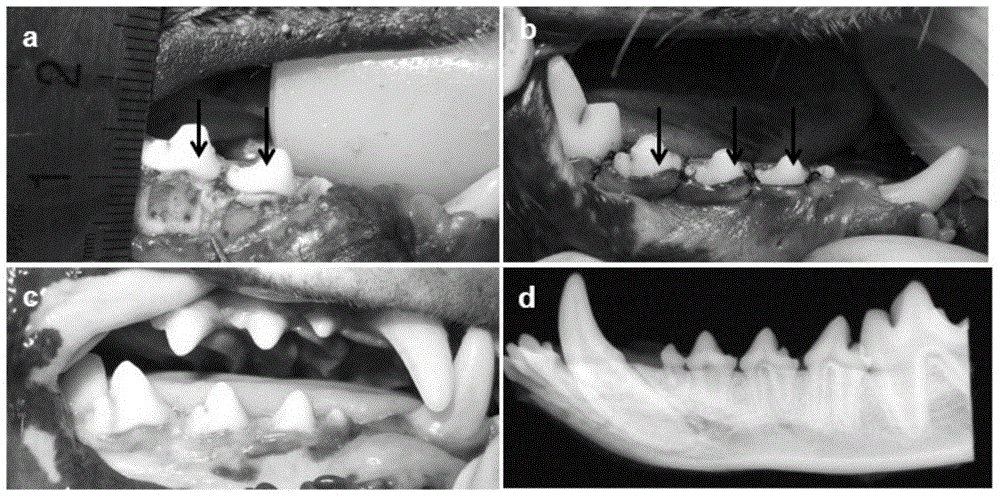

[0041] Example 3 (basement membrane 100 μm, scaffold layer 2000 μm)

[0042](1) Preparation of silk fibroin solution: a) Degumming: Put 100g of silkworm silk (Zhejiang Huazhi Silk Co., Ltd., 5A grade) into 5L of 2M sodium carbonate aqueous solution, bathe in 98°C for 30min, and wash with deionized water , this process was repeated 3 times to remove the sericin and leave the silk fibroin, and dry the silk fibroin at 50°C to obtain 70g of dried silk fibroin for later use; b) dissolving: dissolve the silk fibroin by mass Dissolve in 9.3M lithium bromide (LiBr) aqueous solution at a volume ratio of 0.20:1, bathe in water at 60°C for 90 minutes until the silk fibroin is fully dissolved, and obtain a mixed solution containing silk fibroin and a small amount of insoluble particles; c) Dialysis: Dilute the mixed solution with The regenerated cellulose dialysis bag (molecular weight cut-off 2000 Dalton) was dialyzed, and the sterile deionized water of 10 times the volume of the mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com