Method of preparing polyaluminocarbosilane

A technology of polyaluminocarbosilane and polycarbosilane, applied in the field of polyaluminocarbosilane, can solve the problems of limited temperature and high cost, and achieve the effects of mild reaction, low cost and reduced synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

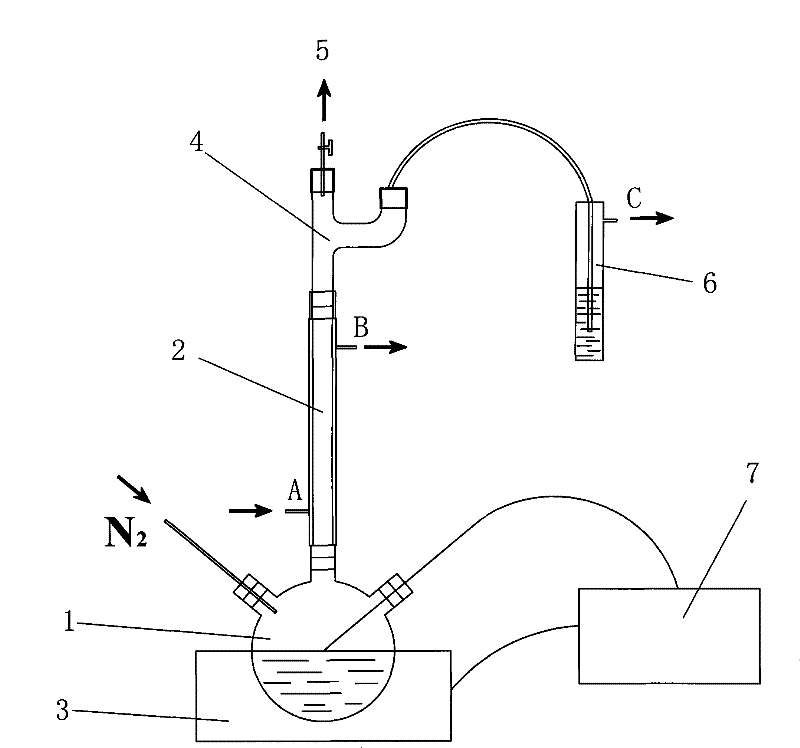

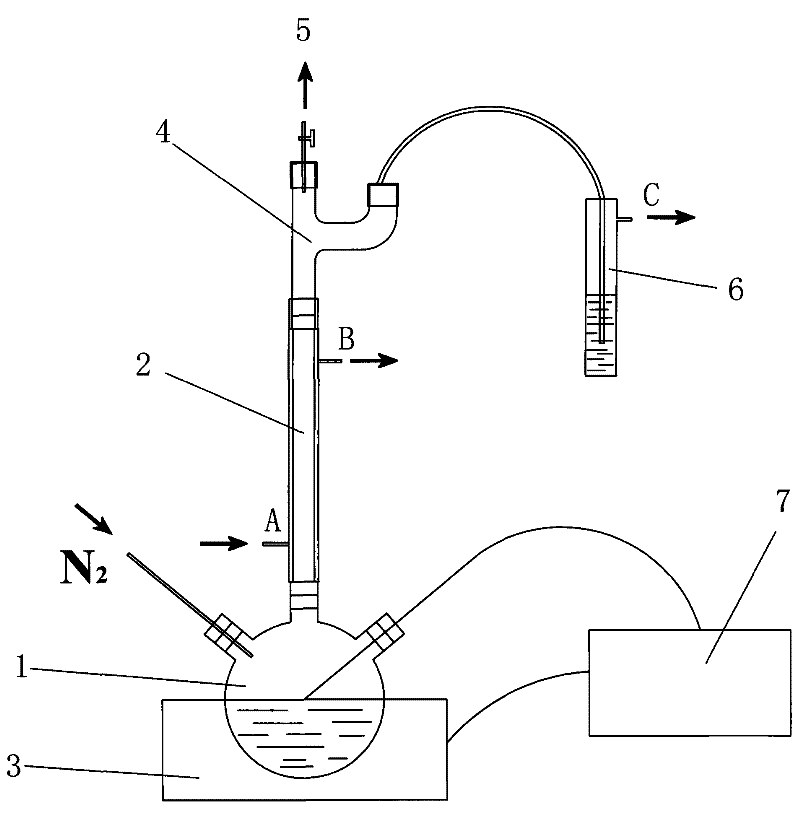

Image

Examples

Embodiment 1

[0027] Embodiment 1: First 1g (mass fraction is 5%) aluminum acetylacetonate is added in the reactor, then add 19g (mass fraction is 95%) liquid polycarbosilane with number average molecular weight of 460 to cover the surface of aluminum acetylacetonate, Stir evenly with a glass rod, pass nitrogen into the reaction kettle, and after 3 times of pumping, control the flow of nitrogen to be stable, keep the reaction kettle under an inert atmosphere at normal pressure, and heat up to 300 ° C for 9 hours. The obtained polyaluminocarbosilane is a fluid golden yellow viscous liquid with a number average molecular weight of 520 and a polydispersity coefficient of 1.17.

Embodiment 2

[0028] Embodiment 2: first 2g (mass fraction is 10%) aluminum acetylacetonate is added in the reactor, then add 18g (mass fraction is 95%) liquid polycarbosilane with number average molecular weight of 460 to cover on the surface of aluminum acetylacetonate, Stir evenly with a glass rod, pass nitrogen into the reaction kettle, and after 3 times of pumping, control the flow of nitrogen to be stable, keep the reaction kettle under an inert atmosphere at normal pressure, and heat up to 300 ° C for 9 hours. The obtained polyaluminocarbosilane was in an orange-yellow viscous liquid state with a number average molecular weight of 540 and a polydispersity coefficient of 1.33.

Embodiment 3

[0029] Example 3: First add about 3g (mass fraction of 15%) aluminum acetylacetonate into the reactor, then add 17g (mass fraction of 85%) of liquid polycarbosilane to cover the surface of aluminum acetylacetonate, and stir evenly with a glass rod , feed nitrogen into the reaction kettle, and after three times of pumping and ventilation, control the nitrogen flow rate to be stable, make the reaction kettle under an inert atmosphere at normal pressure, and raise the temperature to 300° C. for 9 hours. The obtained polyaluminocarbosilane was a yellow-brown viscous liquid with a number average molecular weight of 550 and a polydispersity coefficient of 1.28.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com