A kind of rectification device and method of vinyl acetate

A technology of vinyl acetate and rectification, applied in the direction of separation methods, chemical instruments and methods, fractionation, etc., to achieve the effect of simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

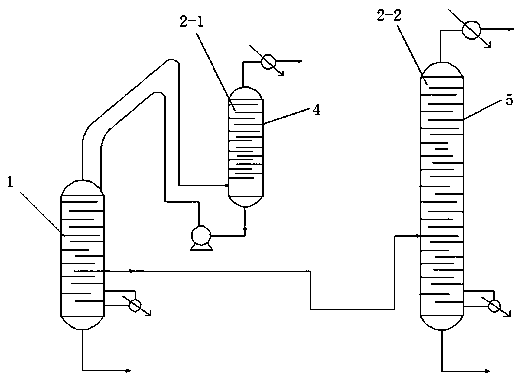

[0023] Embodiment 1, a kind of rectification method of vinyl acetate, comprises vinyl acetate rectification unit, see figure 1 , including primary rectification tower 1, secondary rectification tower Ⅰ2-1 and secondary rectification tower II 2-2, primary rectification tower 1 has 44 trays in total, and the feed plate is the 25th tray, and the second The first-stage rectification tower I2-1 has 45 trays, and the second-stage rectification tower II2-2 has 99 trays; the rectification section of the first-stage rectification tower 1 is connected with the second-stage rectification tower I2-1, and the second The rectification column I2-1 is provided with a VAC extraction outlet 4, and the VAC extraction outlet 4 is arranged at the 25th tray. The stripping section of the first rectification tower 1 is connected with the second rectification tower II2-2, the feed plate of the second rectification tower II2-2 is the 24th tray, and the second rectification tower II2-2 is equipped with ...

Embodiment 2

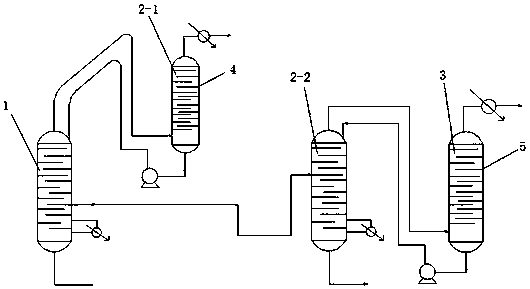

[0029] Embodiment 2, a kind of rectification method of vinyl acetate, comprises vinyl acetate rectification unit, see figure 2 , including a first-stage rectification tower 1, a second-stage rectification tower I2-1, a second-stage rectification tower II2-2 and a third-stage rectification tower. The primary rectification column 1 has 44 trays in total, the feed plate is the 25th tray, the secondary rectification column I2-1 has 45 trays, and the secondary rectification column II2-2 has 44 trays, The three-stage rectification column 3 has 45 trays. The secondary rectification column I2-1 is provided with a VAC extraction outlet 4, and the VAC extraction outlet 4 is arranged at the 25th tray. The stripping section of the primary rectification tower 1 is connected with the secondary rectification tower Ⅱ2-2, the feed plate of the secondary rectification tower Ⅱ2-2 is the 24th tray, and the secondary rectification tower Ⅱ2-2 is connected with the third stage The three-stage rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com