Preparation method of surface devitrified glass-ceramics

A glass-ceramic and crystallization technology, which is applied in the field of surface crystallization glass-ceramic preparation, can solve the problems of low efficiency and achieve the effect of simple process, good effect and clear steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing surface devitrified glass-ceramics, which comprises:

[0029] Step 1. Provide raw materials, which include zinc oxide, boron oxide and silicon dioxide with a molar ratio of (25-60):(5-50):(5-30); grind and mix the raw materials;

[0030] Step 2, heating and melting the raw materials obtained in step 1 to obtain molten glass;

[0031] Step 3, forming and annealing the molten glass obtained in step 2 to obtain an intermediate product;

[0032] Step 4, heat-treating the intermediate product obtained in Step 3 to obtain surface devitrification glass-ceramics.

[0033] Among the above raw materials, the molar ratio of zinc oxide, boron oxide and silicon dioxide is preferably (30-60):(25-40):(5-20), more preferably 60:30:10. As a preferred version of the present invention, the raw material also includes aluminum oxide and / or sodium oxide; the molar ratio of aluminum oxide to zinc oxide is (0-4): (25-60); the molar ratio of sodiu...

Embodiment 1

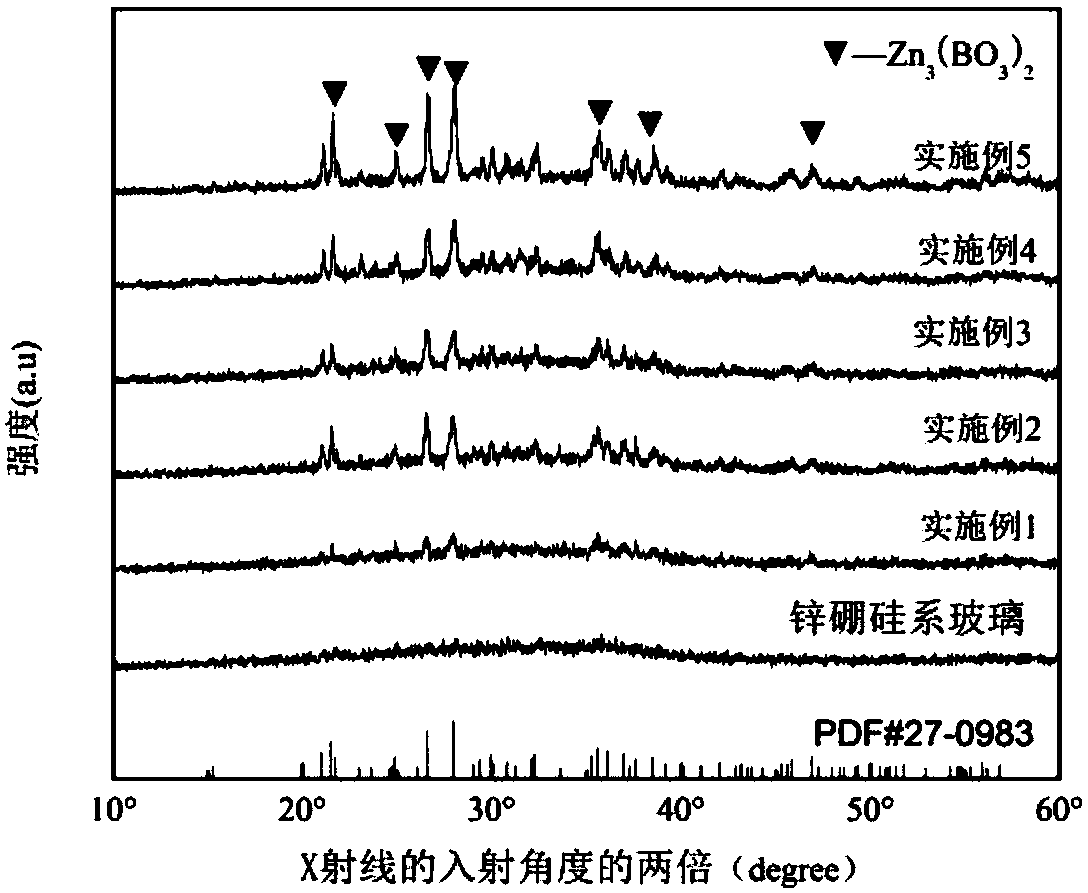

[0044] The glass raw material composition is 60% ZnO, 30% B 2 o 3 , 10% SiO2 2 , Weigh 120g of glass raw materials, mix the raw materials evenly and place them in a platinum-rhodium alloy crucible, put them in a high-temperature furnace at 1400°C for 2 hours, then pour the melt into a preheated graphite mold for molding, and quickly send it into In the annealing furnace, keep warm at 550°C for 2 hours, and then cool to room temperature with the furnace. Then cut the glass into glass pieces of 5*5*20mm and put them at 650° C. for 5 hours to obtain surface crystallized glass-ceramics. The thickness of the devitrified layer measured by scanning electron microscope is about 53 μm. Grind the heat-treated surface crystallization glass into powder, and the phase measured by XRD is Zn 3 (BO 3 ) 2 ,Such as figure 2 Shown in Example 1.

Embodiment 2

[0046] The glass raw material composition is 60% ZnO, 30% B 2 o 3 , 10% SiO2 2 , Weigh 120g of glass raw materials, mix the raw materials evenly and place them in a platinum-rhodium alloy crucible, put them in a high-temperature furnace at 1400°C for 2 hours, then pour the melt into a preheated graphite mold for molding, and quickly send it into In the annealing furnace, keep warm at 550°C for 2 hours, and then cool to room temperature with the furnace for later use. Then cut the glass into 5*5*20mm glass block, put it in 585℃ for 2h, then raise it to 650℃ at 5℃ / min and keep it for 5h to get crystallized glass. The thickness of crystallized layer measured by scanning electron microscope is approx. 65 μm. Grind the heat-treated surface crystallization glass into powder, and the phase measured by XRD is Zn 3 (BO 3 ) 2 ,Such as figure 2 Shown in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com