Controllable Elastic Energy Release and Recovery System

A recovery system and elastic energy technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of mechanical brake systems, waste of recyclable energy, lack of development, etc., to achieve beneficial Environmental protection, improvement of utilization rate, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

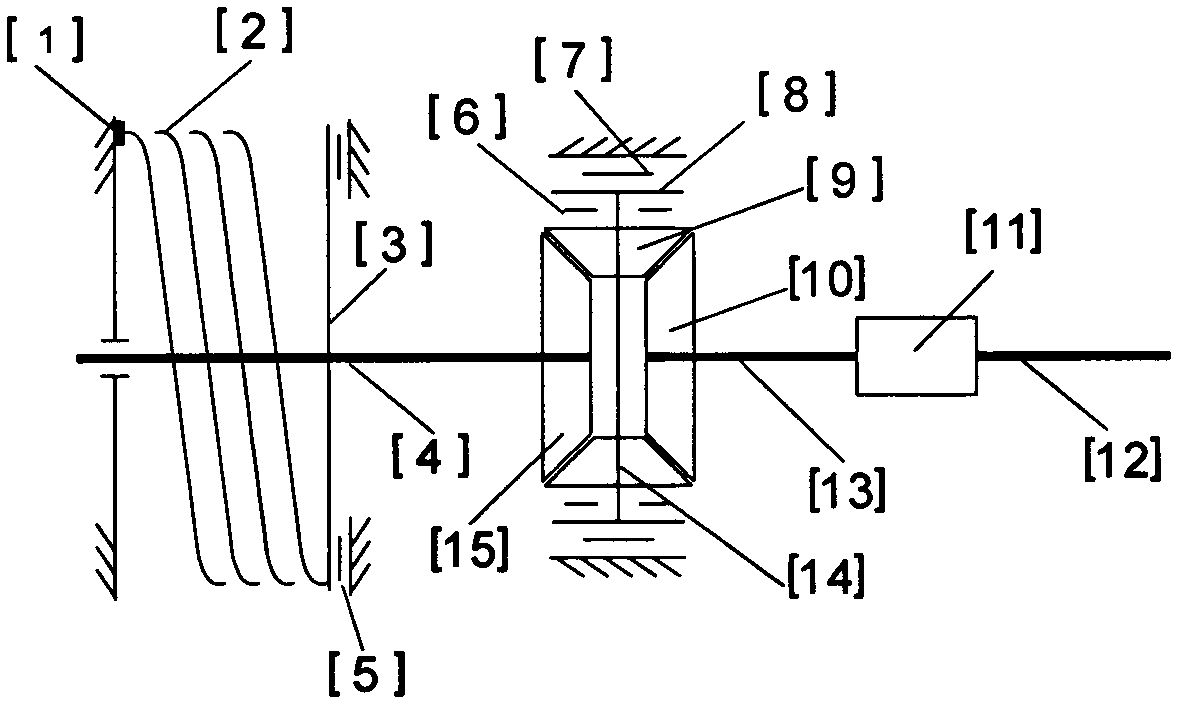

Embodiment 1

[0034] Example 1: Combining figure 1 , fix one end of the coil spring (or other elastically deformable elements or components) 2 and install the pressure sensor 1, one end is installed on the drive wheel 3 as a free end, the drive wheel 3 is fixed on the drive shaft 4, and the differential A bevel gear 15 of the device is fixed on the transmission shaft 4 as a driving bevel gear, and the other bevel gear 10 is used as an output bevel gear and is connected with a transmission 11 capable of bidirectional rotation and transmission through a transmission shaft 13; bevel gears 15 and 10, planetary gears 9. Planet carrier 14, brake disc 8 and locking mechanisms (such as clutches, brakes, claws, etc.) 6 and 7 act as reversing mechanisms when the system requires transmission and rotation directions to change; pressure sensor 1 provides volume for the control system. The pressure signal of the spring 2 enables the control system to accurately execute the control task; the locking mecha...

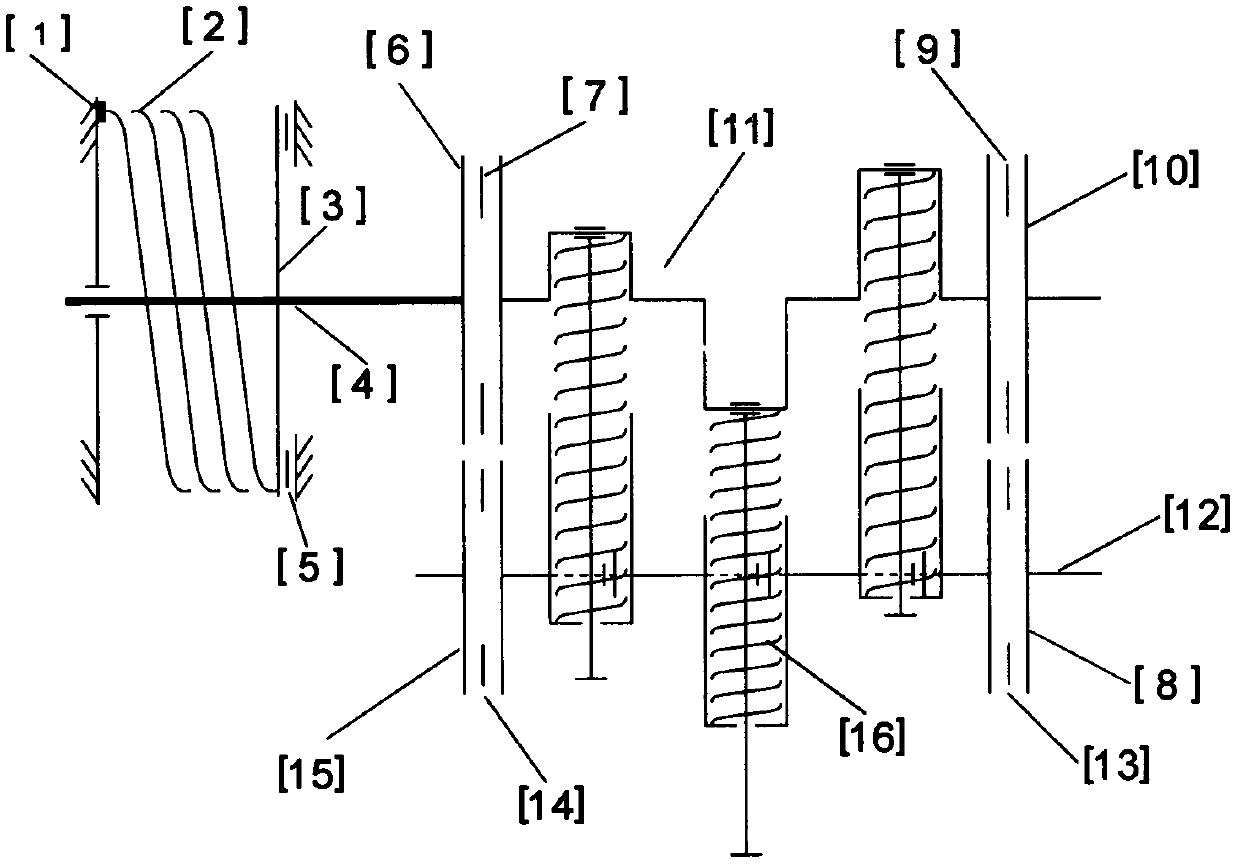

Embodiment 2

[0035] Example 2: Combining figure 2 , it is on the basis of embodiment 1, transmission 11 uses crankshaft stroke variable elastic continuously variable transmission 11, combined with embodiments 1, 2, 5, 6, 7, 9, 14, 15 of stroke variable elastic continuously variable transmission Etc., the transmission mode can either choose a compressible elastic element or assembly as the elastic connecting rod transmission torque, or a rigid connecting rod to drive a rotatable coil spring transmission torque; the elastic element of the crankshaft stroke variable elastic continuously variable transmission 11 Or assembly 16 can use certain initial pressure or initial pressure (or energy) and elastic element or assembly or combination that elastic coefficient can change; Transmission wheel 8 and 15 and 10, recovery wheel 6 and locking mechanism (as clutch , brakes, claws, etc.) 7, 9, 13, 14 are used to change the transmission direction when the system changes energy release and recovery tas...

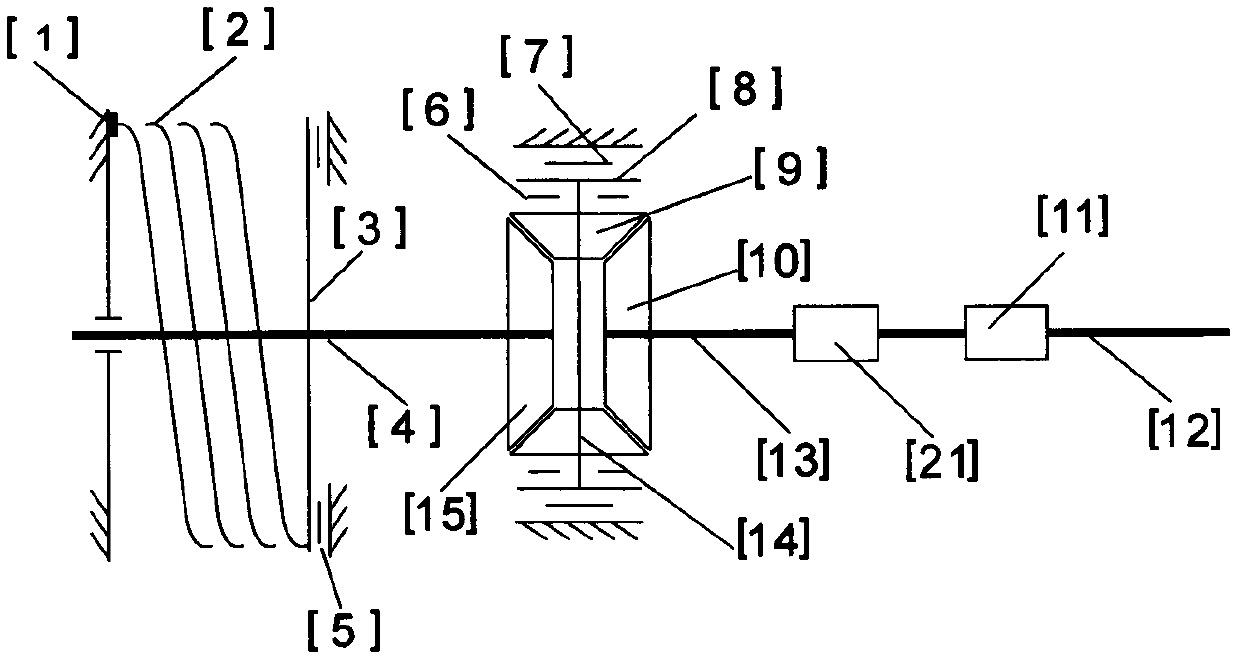

Embodiment 3

[0036] Example 3: Binding image 3, it is on the basis of embodiment 2, combined with embodiments 3, 4, 8, 10, 11, 12, 13, 16, etc. Step transmission 11, since coil spring-like elastic elements or components cannot rotate and transmit in both directions, a suitable reversing mechanism 20 needs to be matched between coil spring 2 and coil spring elastic continuously variable transmission 11 to enable the system to successfully complete energy release and recovery tasks . The transmission mode of coil spring variable elastic CVT 11 mainly uses rotatable coil springs (or other elements or components that can undergo elastic deformation) to transmit torque, and the elastic components or components of coil spring CVT 11 can be Using an elastic element or component or combination with a certain initial pressure or elastic coefficient, or whose initial pressure (or energy) or elastic coefficient can be changed, can also use a coil spring elastic continuously variable transmission wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com