Hydraulic drive internal combustion engine

A technology of hydraulic transmission and internal combustion engine, applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as incompleteness, achieve the effects of low noise, reduce friction loss, and improve mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

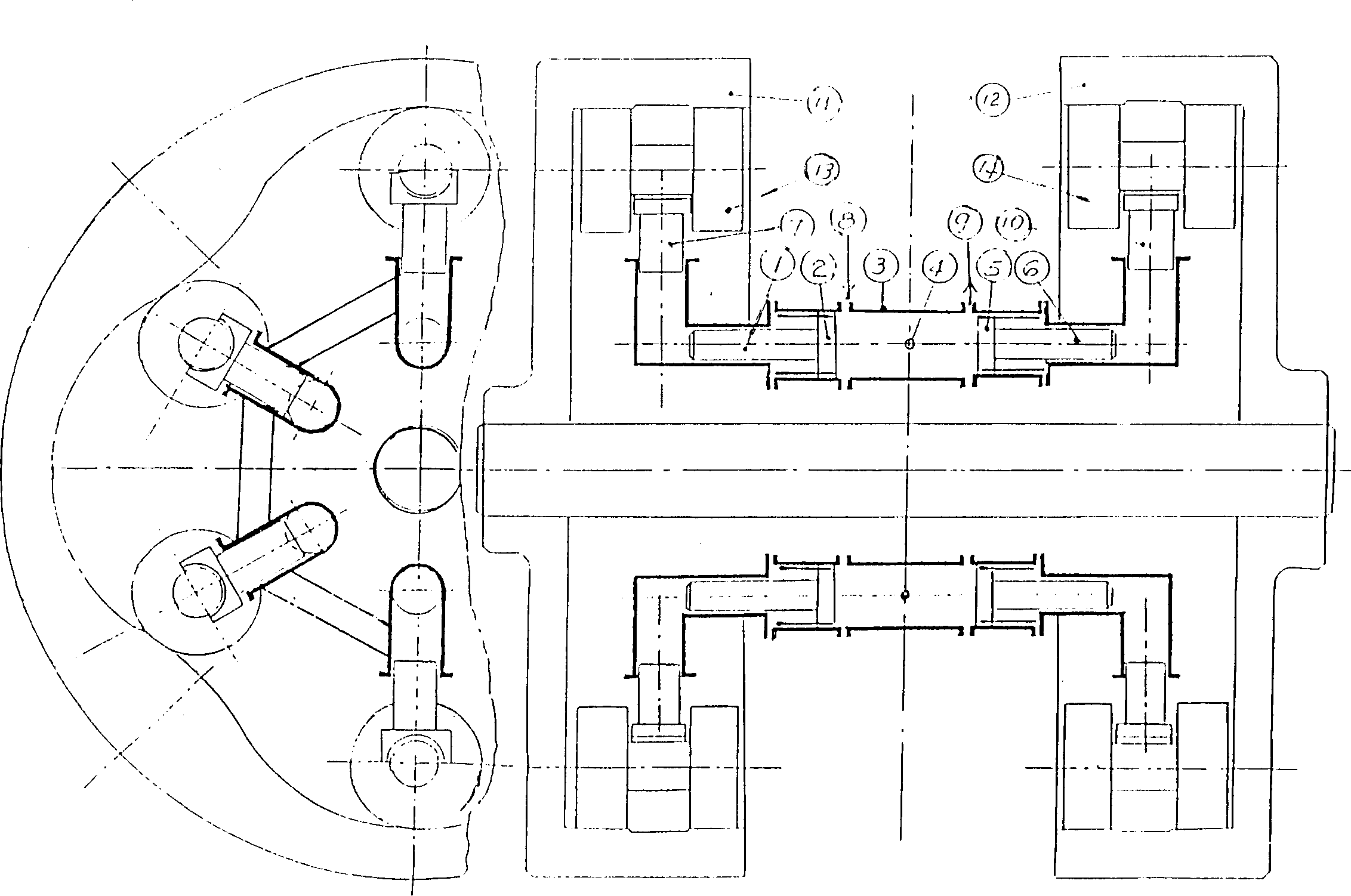

[0019] The whole machine consists of several units (attached figure 1 ), the middle is the internal combustion cylinder, the two sides are the hydraulic cylinder, and the two ends are the intake end cam and the exhaust end cam. The units are arranged symmetrically with respect to the cam.

[0020] The unit structure is attached Figure 1 , of which 1 is the hydraulic pump plunger at the intake end, 2 is the intake end piston, 3 is the cylinder, 4 is the fuel injection nozzle, 5 is the exhaust end piston, 6 is the exhaust end pump plunger, and 7 is the intake end Hydraulic motor plunger, 8 is the intake port, 9 is the exhaust port, 10 is the exhaust end motor plunger, 11 is the intake end cam, 12 is the exhaust end cam, 13 and 14 are the rollers.

[0021] When the two pistons 2 and 5 are close to the inner dead center position, the fuel injection nozzle 4 catches fire and burns, the pressure in the cylinder 3 rises, and pushes the pistons 2 and 5 and the pump plungers 1 and 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com