A method for preparing quartz needles by etching capillaries with hydrofluoric acid

A technology of capillary and hydrofluoric acid, which is applied to parts, instruments, and measuring devices of particle separator tubes, can solve problems such as difficulty in automation, poor service life, and low usage of hydrofluoric acid, and achieve stability that is not easy to clog Sexuality, long service life, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of quartz needles with different inner diameters:

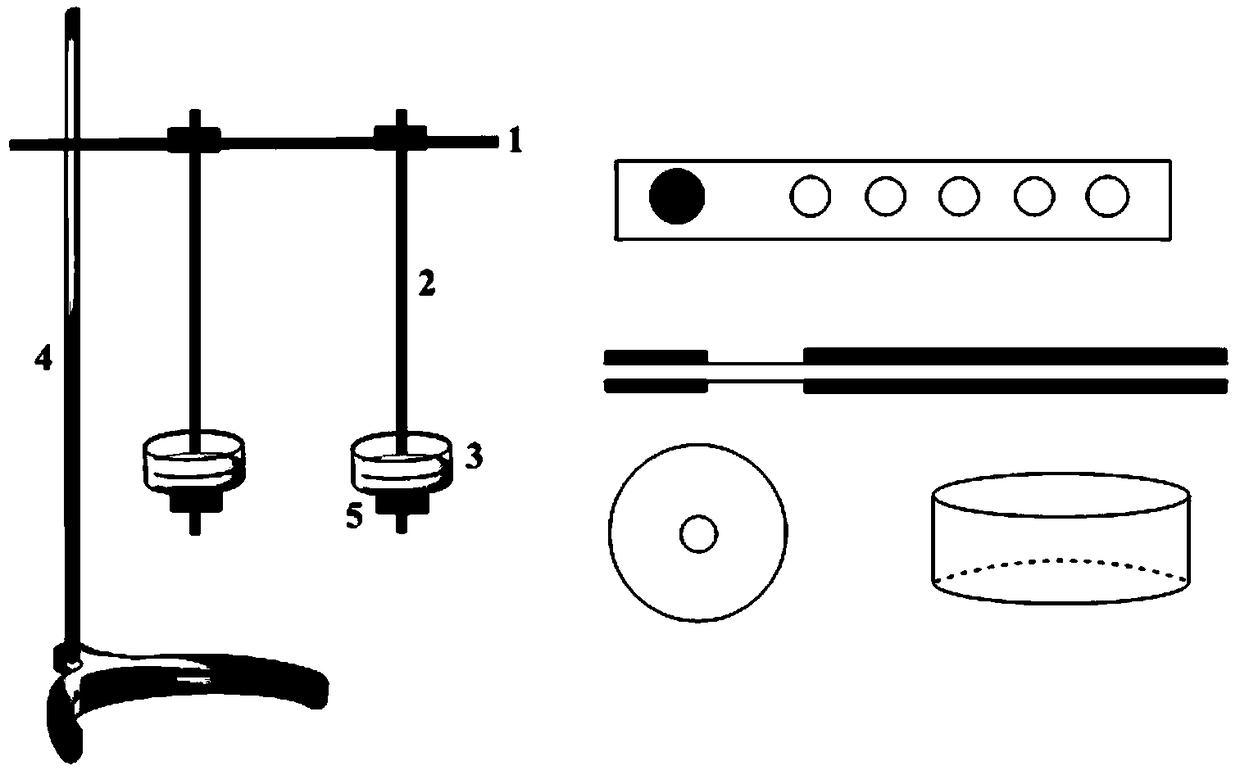

[0028] Take 2 capillaries with a length of 10 cm and an inner diameter of 3 μm, 10 μm, 15 μm, and 20 μm respectively. After scraping off the polyamide coating with a blade, fix them in the designed device respectively, such as figure 1 As shown (the porous plate is fixed on the iron stand, the capillary is fixed in the hole of the porous plate, the lower end of the capillary passes through the hole at the bottom center of the hydrofluoric acid storage tube, the hole wall is closely attached to the outer wall of the capillary, and the capillary passes through the hole The silica gel plug, the wall of the silica gel plug hole is closely attached to the outer wall of the capillary, and the silica gel plug is used to fix the capillary outside the bottom of the hydrofluoric acid storage tube); add 20 μL of 40% hydrofluoric acid, etch at room temperature until the capillary breaks, and the prepared Quartz needles...

Embodiment 2

[0030] Application of quartz needles in liquid chromatography-mass spectrometry:

[0031] Select the quartz needle of 10 μm inner diameter that embodiment 1 makes as electrospray needle, investigate its spray stability and life: flow rate: 100nL / min; Mobile phase: the aqueous solution of 2% acetonitrile, 0.1% formic acid; Spray voltage: 1.9 kV. Depend on Figure 4 It can be seen that the spray stability is very good, and after 60 hours of continuous spraying, it still has good stability, which fully proves the potential value of the quartz needle in electrospray applications.

Embodiment 3

[0033] Preparation of microinjection needles:

[0034] Take a 10cm 3μm capillary tube, use an alcohol lamp to carbonize the polyamide coating, then wipe off the carbonized polyamide layer with absorbent cotton dipped in alcohol, and fix it in the designed device (the porous plate is fixed on the iron stand, and the hole in the porous plate The capillary is internally fixed, and the lower end of the capillary passes through the hole in the center of the bottom of the hydrofluoric acid storage tube. A silicone stopper secures the capillary outside the bottom of the hydrofluoric acid reservoir), such as figure 1 As shown; add 20 μL of 40% hydrofluoric acid, etch at room temperature until the capillary breaks, and the prepared quartz needle is as follows: image 3 shown. The outer diameter of microinjection needles is controllable (only 10.0±0.3 μm), and capillaries with different inner diameters are selected for preparation according to different needs.

[0035] The microinjec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com