Three-dimensional woven fabric coated with multiple layers of emulsion strips

A woven fabric and latex technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of increasing the thickness of the fabric, not improving the air permeability and moisture permeability of the foam strip, and low overall strength, and achieving the effect of increasing the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

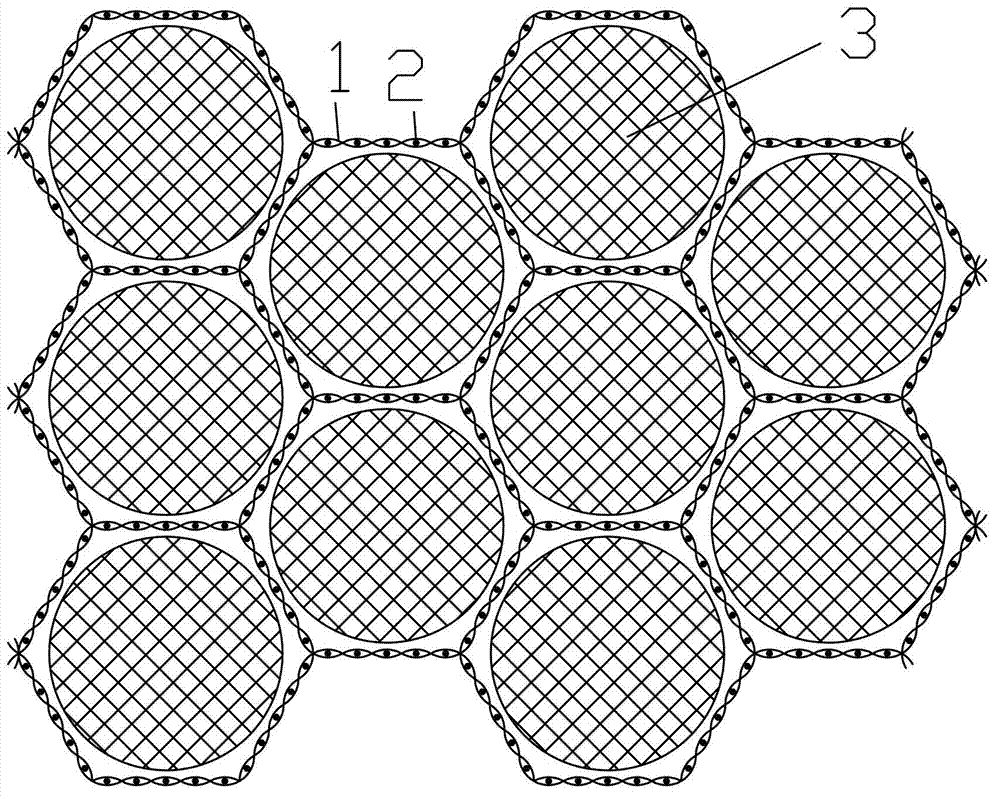

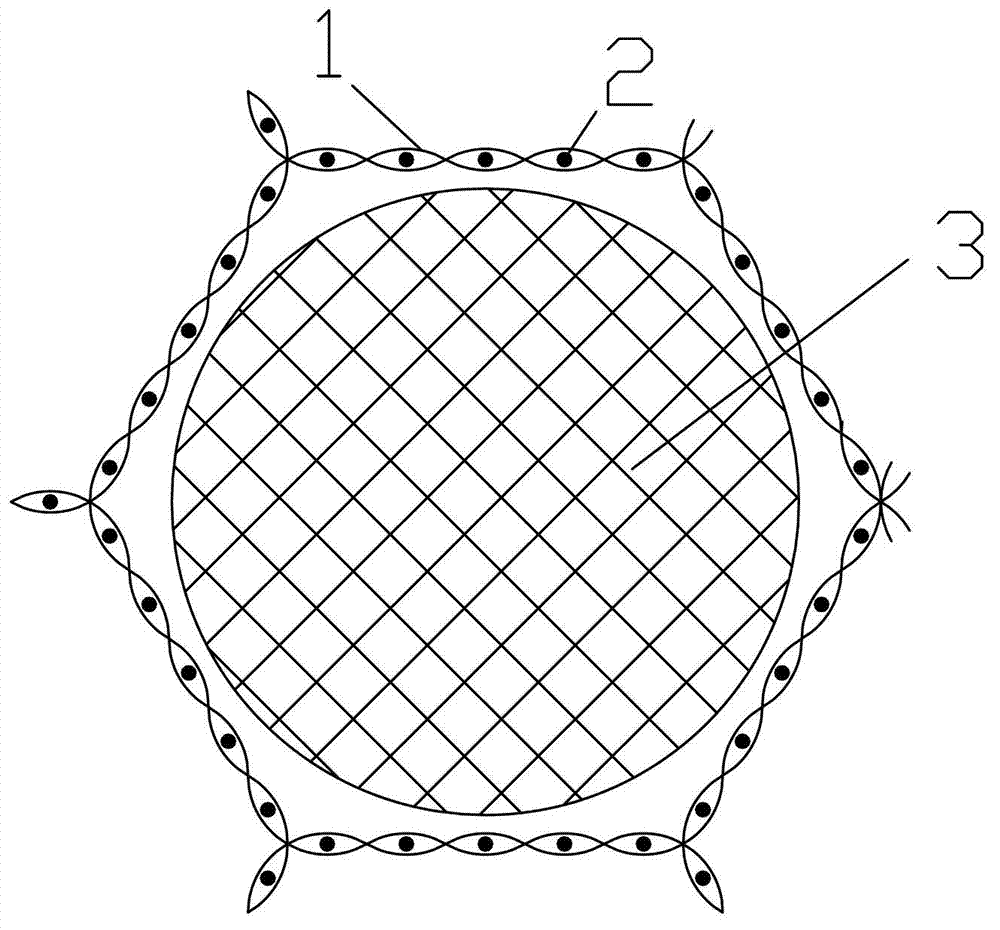

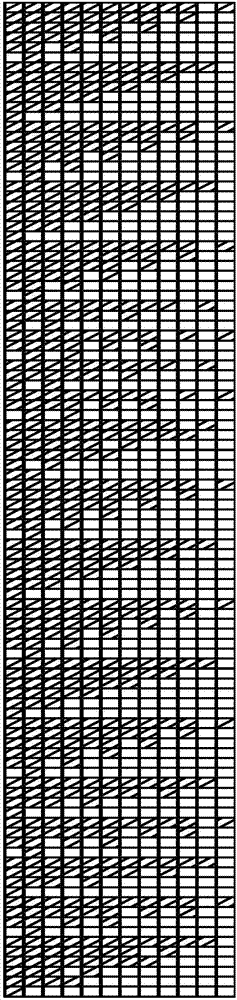

[0023] Such as figure 1 and figure 2 As shown, a three-dimensional woven fabric coated with multi-layer latex strips includes warp yarn 1, weft yarn 2 and latex strip 3, and the three-dimensional woven fabric is composed of several repeated tubular woven fabric units, and the tubular woven fabric unit includes several layers of woven fabrics , each layer of woven fabric is formed by interweaving warp yarn 1 and weft yarn 2, and the tubular woven fabric formed by interweaving warp yarn 1 and weft yarn 2 is any one of plain weave or twill weave. In this embodiment, the tubular woven fabric unit is a double-layer woven fabric, and the woven fabric adopts a plain weave as a basic weave. A tubular woven fabric unit is formed by interweaving 30 weft yarns 2 and warp yarns 1, and every two adjacent t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com