A kind of preparation method of cross-linked aliphatic polycarbonate

A polycarbonate and aliphatic technology, applied in the field of polymer materials, can solve the problems of toxicity, non-compliance with environmental protection requirements of materials, and difficulty in controlling the degree of cross-linking of polycarbonate, and achieves low synthesis cost, low raw material cost, and polymerization product. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

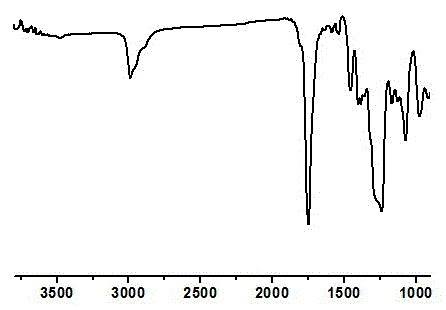

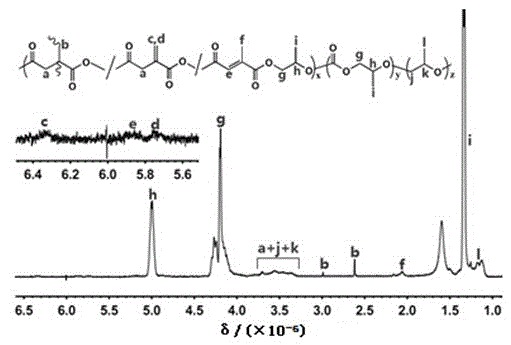

Embodiment 1

[0028] Add 0.5g of zinc glutarate, 4.03g (0.036mol) of itaconic anhydride, and 50 mL (0.72mol) of propylene oxide into the pre-dried reaction kettle, fill it with carbon dioxide gas, adjust the pressure to 5.2MPa, 60°C The reaction was mechanically stirred for 40 hours. The reaction was terminated with a methanol solution containing 5% hydrochloric acid, washed with methanol, and vacuum-dried at 35°C to constant weight to obtain 50.0 g of cross-linked aliphatic polycarbonate. The gel content in the polymer is 34.7%, the thermal decomposition temperature is 250.4 ℃, the tensile strength is 12.5 MPa, and the elongation at break is 604.1%.

Embodiment 2

[0030]Add 0.5g of zinc glutarate, 1.61g (0.0144mol) of itaconic anhydride, and 50 mL (0.72mol) of propylene oxide into a pre-dried reactor, fill with carbon dioxide gas, adjust the pressure to 5.2MPa, and store at 70°C The reaction was mechanically stirred for 40 hours. The reaction was terminated with a methanol solution containing 5% hydrochloric acid, washed with methanol, and vacuum-dried at 35°C to constant weight to obtain 51.2 g of cross-linked aliphatic polycarbonate. The gel content in the polymer is 35.2%, the thermal decomposition temperature is 257.8°C, the tensile strength is 20.2 MPa, and the elongation at break is 596.7%.

Embodiment 3

[0032] Add 0.5g of zinc glutarate, 4.03g (0.036mol) of itaconic anhydride, and 50 mL (0.72mol) of propylene oxide into the pre-dried reaction kettle, fill it with carbon dioxide gas, adjust the pressure to 5.2MPa, and store at 70°C The reaction was mechanically stirred for 30 h, and the reaction was terminated with a methanol solution containing 5% hydrochloric acid, washed with methanol, and vacuum-dried at 35°C to constant weight to obtain 55.8 g of cross-linked aliphatic polycarbonate. The gel content in the polymer is 49.7%, the thermal decomposition temperature is 250.9°C, the tensile strength is 21.0MPa, and the elongation at break is 567.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com