Three-dimensional forming device and method

A technology of three-dimensional molding and spraying device, which is applied in the direction of additive processing, etc., can solve the problems of slow molding speed, slow self-leveling speed, and difficult control of surface accuracy, so as to avoid resistance, improve speed and reliability, and reduce scratches or the effect of stretching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] As mentioned in the background technology, in the existing three-dimensional molding technology, delamination and curing are completed by immersing in the resin liquid. When processing parts with closed cavities, it is easy to cause unnecessary resin liquid to be sealed or remain in the parts. The interior affects the final molding accuracy of the parts, and the method in the prior art is relatively wasteful of materials and has low efficiency.

[0043] Therefore, the present invention proposes a three-dimensional forming device and method capable of achieving high efficiency, high precision, and material saving.

[0044] Next, the specific technical solution of the present invention will be introduced in detail.

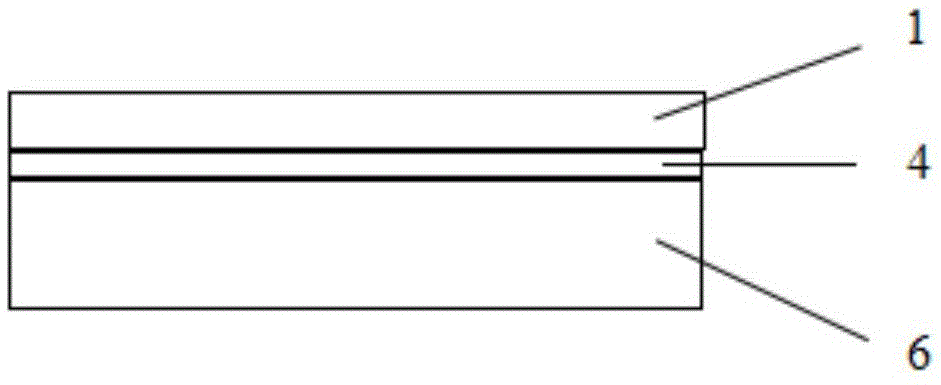

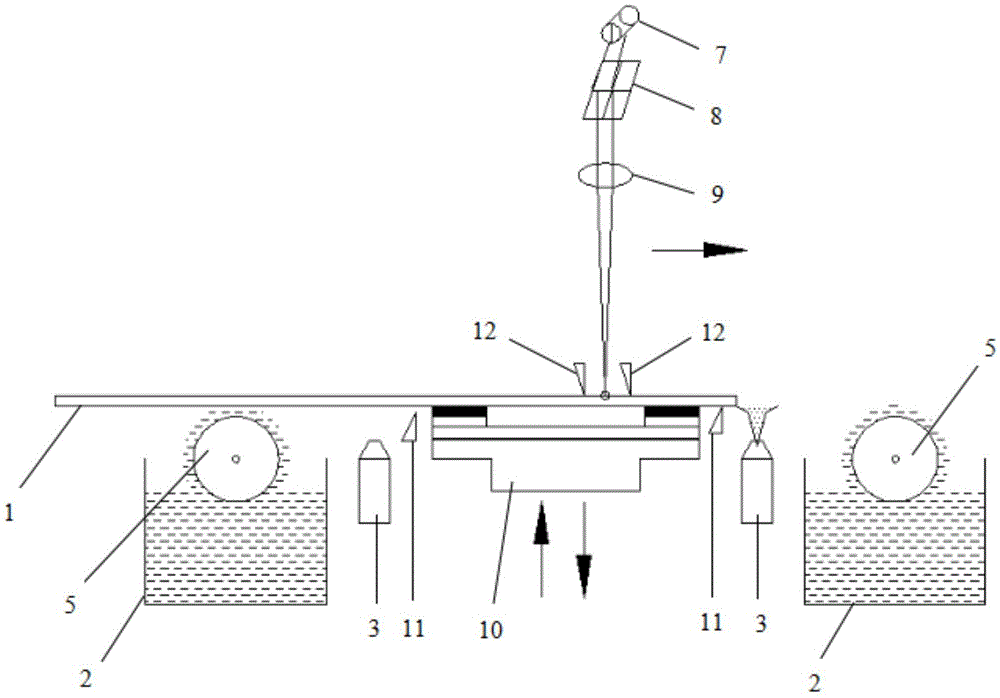

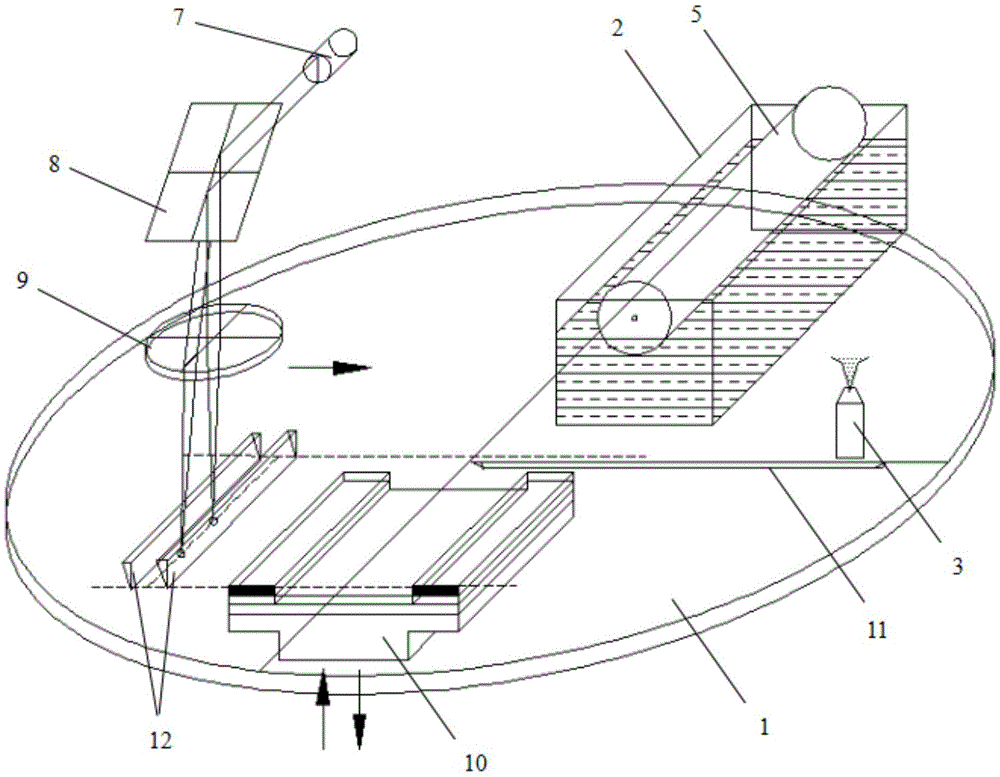

[0045] The three-dimensional molding device based on the base layer in the present invention includes a base layer 1 and a substrate forming mechanism, an exposure mechanism, a supporting mechanism, and a peeling mechanism. mechanism, wherein the base layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com