Removed method for poisonous component of cleaved product in hexafluoropropylene manufacturing technique

A production process and cracking product technology, applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., can solve problems such as complex process routes in the production process of hexafluoropropylene, leakage of perfluoroisobutylene, threats to personal safety of employees, etc. To achieve the effect of guaranteeing personal safety, cleaning the production process, and reducing the pollution of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

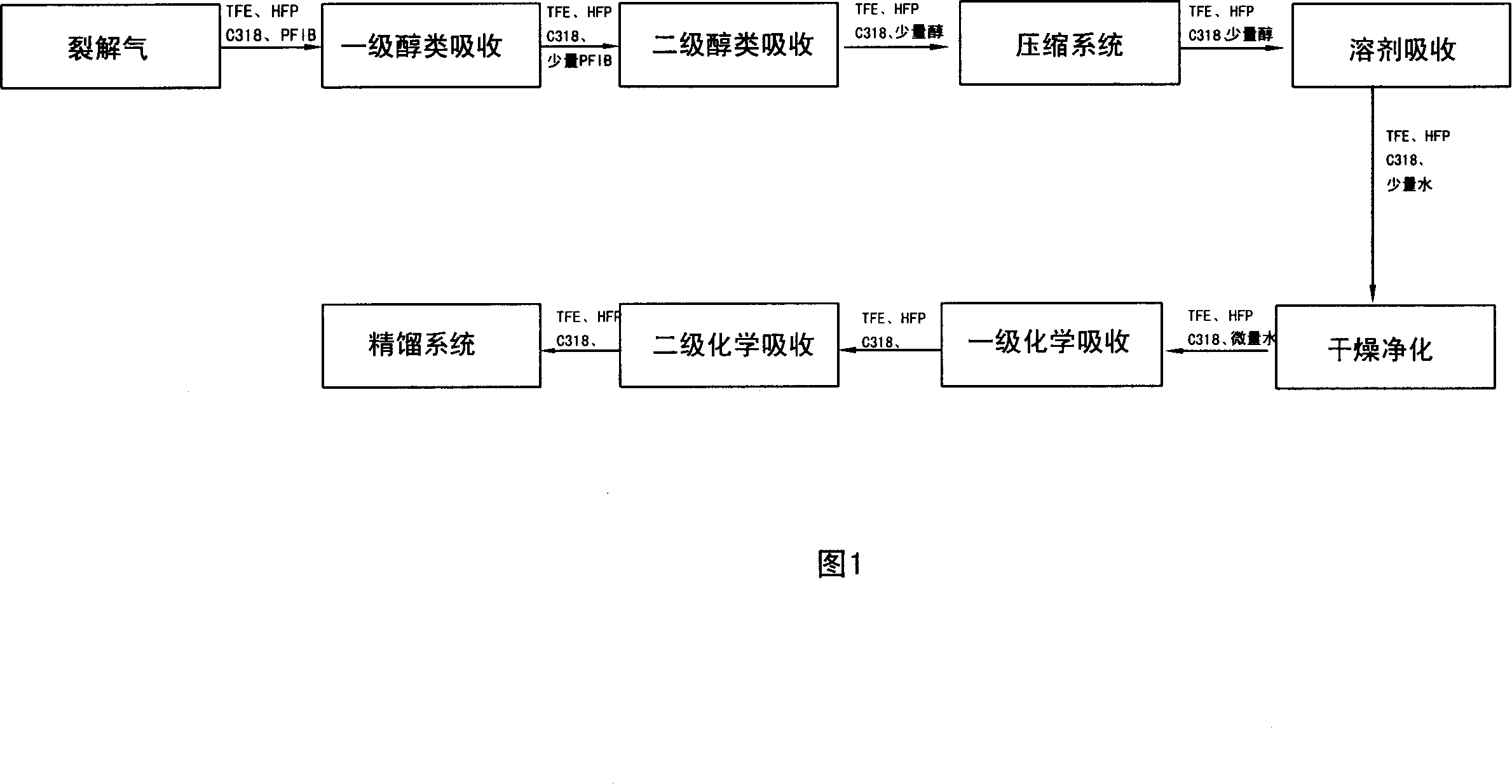

[0014] Tetrafluoroethylene and C 318 Carry out cracking with the mixed charging capacity of 300Kg / h, in the cracking component, PFIB content is about 6%, and the material (cracking gas) that comes out from cracking furnace enters alcohols material absorption tower (adopted two-stage absorption among Fig. 1), alcohol Ethanol is used for absorption, and the spray volume of ethanol is 1-5m 3 / h, the absorption pressure is normal pressure or slightly positive pressure, and the temperature is about -10-120°C. After ethanol absorption, there is no peak of PFIB in the pyrolysis material. After the ethanol is absorbed, the material enters the compressor to increase the pressure to 0.2-0.6Mpa, and then enters the solvent absorption. The solvent absorption adopts 30% sodium carbonate aqueous solution, and the sodium carbonate aqueous solution is 1-5m 3 / h flow rate spraying to remove a small amount of alcohol and acidic substances in the system. The absorbed material enters the silica ...

Embodiment 2

[0016] According to Embodiment 1, methanol is used for alcohol absorption, and water is used for solvent absorption.

Embodiment 3

[0018] According to the first embodiment, methanol is used for alcohol absorption, 25% calcium chloride aqueous solution is used for solvent absorption, and solid sodium hydroxide is used for chemical absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com