Alloy combined unfired sliding plate

An alloy and skateboard technology, applied in the field of refractory products - skateboard bricks and non-burning skateboards, can solve the problems of increased manufacturing costs and cumbersome process routes of skateboard bricks, so as to reduce process costs, reduce damage to the environment and employees, and achieve economic benefits. objective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

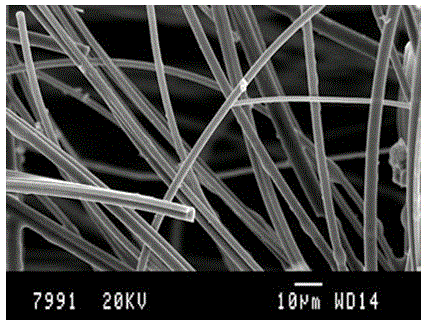

Image

Examples

Embodiment 1

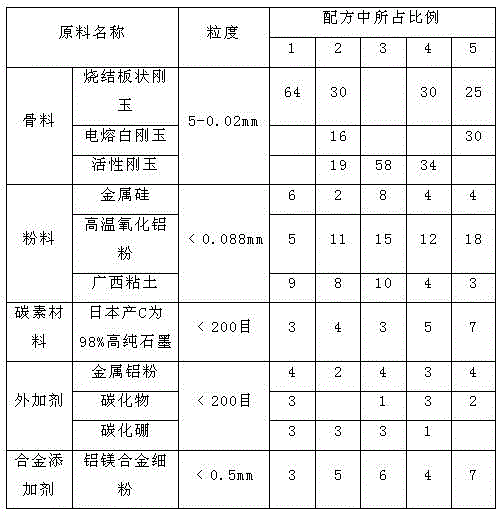

[0023] Firstly, prepare according to the ratio and particle size of the pellets and powders used in the alloy of the present invention combined with the non-burning slide plate given in the embodiment of Table 1.

[0024] The preparation method is:

[0025] After batching each ingredient according to the specified ratio, pre-mix all the powder materials, carbon materials, and admixtures in the pre-mixing equipment to make a mixed powder for later use; then use a large wet mill to mix according to the following feeding sequence : Put the aggregate into the mixer and knead for 3-5 minutes, add the binder (4.5% phenolic resin) and knead for another 6 minutes, then add the above-mentioned prepared mixed powder and knead for 35 minutes, and discharge; use 1000 The bricks are formed by a 1-ton friction press, and the bricks are dried at 180°C for 30 hours, and finally hooped, ground, coated, and packaged to obtain an alloy-bonded non-burning skateboard. See Table 2 for the inspecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com