Straw comprehensive utilization method

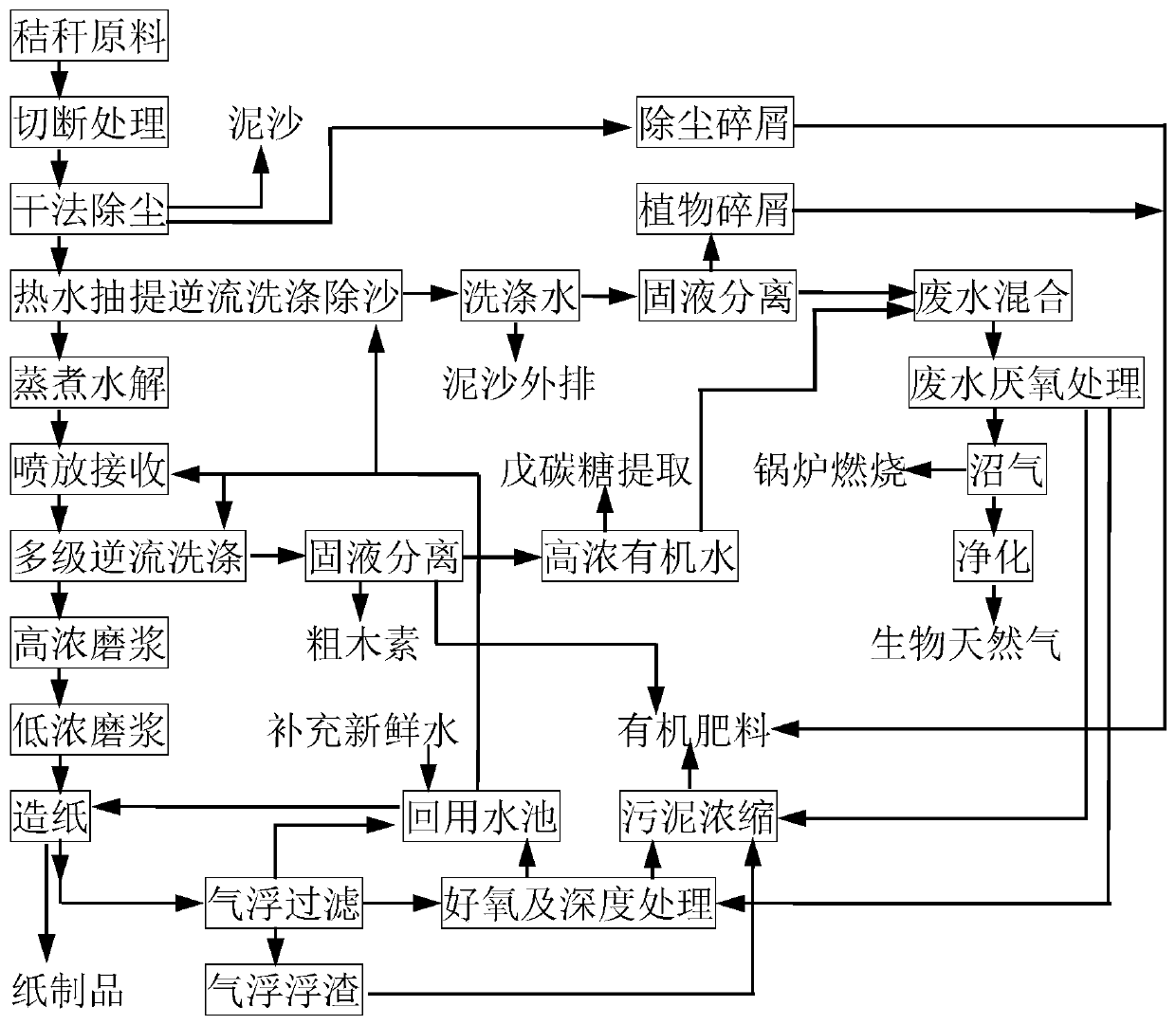

A straw and dry dust removal technology, applied in the field of pulp and paper, can solve the problems of black liquor extraction rate and evaporation efficiency not as good as wood raw materials, increased chemical additives, poor pulp drainage, etc., to improve porosity and filtration Water-based, reducing steam and power consumption, fully absorbing water and swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The corn stalks are continuously sent to the straw cutting machine through the belt conveyor, and the straw materials are cut to a length of 30-50mm with a pass rate of 75%; then sent to the dust collector through the belt conveyor; the straw materials are loosely turned in the roller dust collector , to sieve out the silt adhering to the material sheet, the sieve hole diameter is 5mm, and separate the debris such as leaves, pith, ears, etc., for the production of organic fertilizer.

[0054] The dust-removed material is sent to the hot water extraction and countercurrent washing desanding device, the extraction and washing time is 60min, the washing water temperature is 80°C, the washing material content is 10% (material-to-water ratio), the extraction and countercurrent washing water is separated from solid and liquid, and sent to the water The treatment system is mixed with high-concentration wastewater and then enters the anaerobic system; the separated sediment is t...

Embodiment 2

[0061] The corn stalks crushed and packed by the picker are unpacked by the automatic unpacking machine and sent to the dust collector through the belt conveyor; the straw materials are loosely turned in the drum dust collector, and the silt adhering to the material is screened out. 6mm, to separate leaves, pith, ears and other debris for the production of organic fertilizer.

[0062] The dust-removed material is sent to the hot water extraction and countercurrent washing desanding device, the extraction and washing time is 180min, the washing water temperature is 100°C, the washing material content is 8% (material-to-water ratio), the extraction and countercurrent washing water is separated from solid and liquid, and sent to the water The treatment system is mixed with high-concentration wastewater and then enters the anaerobic system; the separated sediment is transported out of the system.

[0063] The straw material after extraction and washing enters the cooking and hydro...

Embodiment 3

[0069] The wheat straw material is continuously fed into the straw cutting machine through the belt conveyor, and the straw material is cut to a length of 30-50mm with a pass rate of 85%; then it is sent into the dust collector through the belt conveyor; the straw material is loosely turned in the roller dust collector , to sieve out the silt adhering to the tablet, the sieve hole diameter is 6mm, and separate the leaves, pith, ears and other debris for the production of organic fertilizer.

[0070]The dust-removed material is sent to the hot water extraction and countercurrent washing desanding device, the extraction and washing time is 120min, the washing water temperature is 100°C, the washing material content is 8% (material-to-water ratio), the extraction and countercurrent washing water is separated from solid and liquid, and sent to the water The treatment system is mixed with high-concentration wastewater and then enters the anaerobic system; the separated sediment is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com