Patents

Literature

45results about How to "Avoid heavy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic bionic adsorbent and application of magnetic bionic adsorbent in treating acid wastewater containing uranium

ActiveCN105413659AOvercoming the long preparation cycleAvoid heavy consumptionOther chemical processesRadioactive contaminantsSorbentSolvent

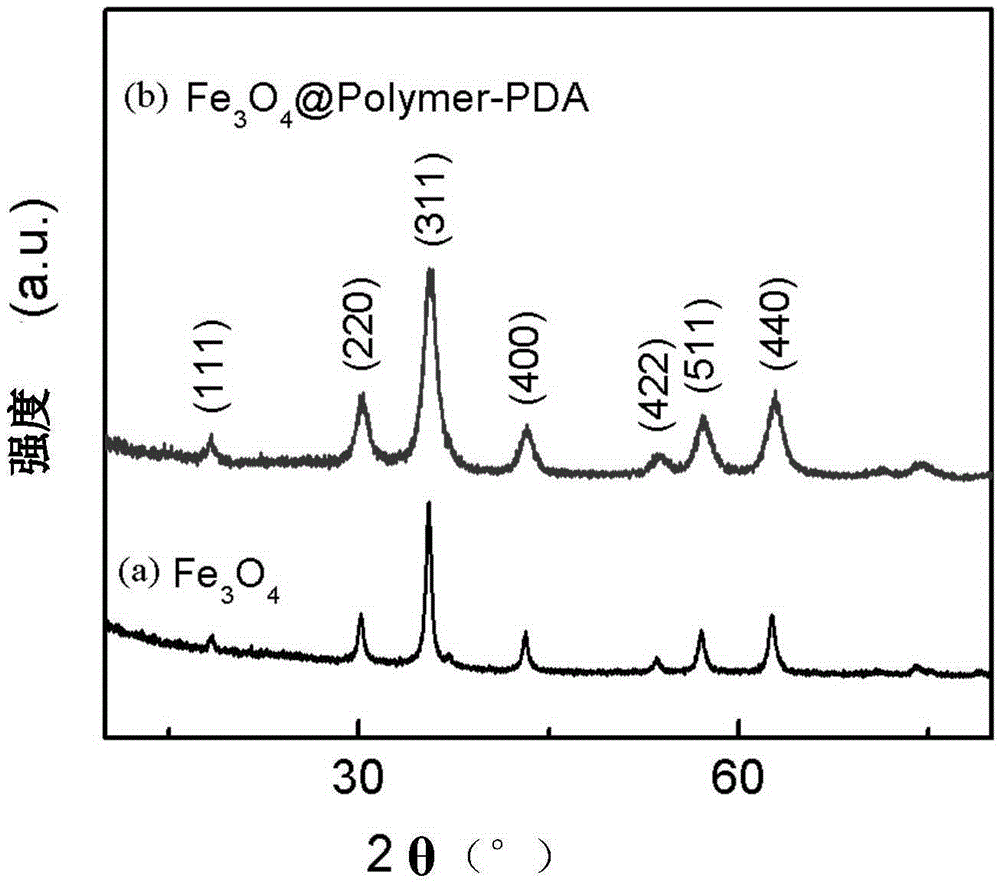

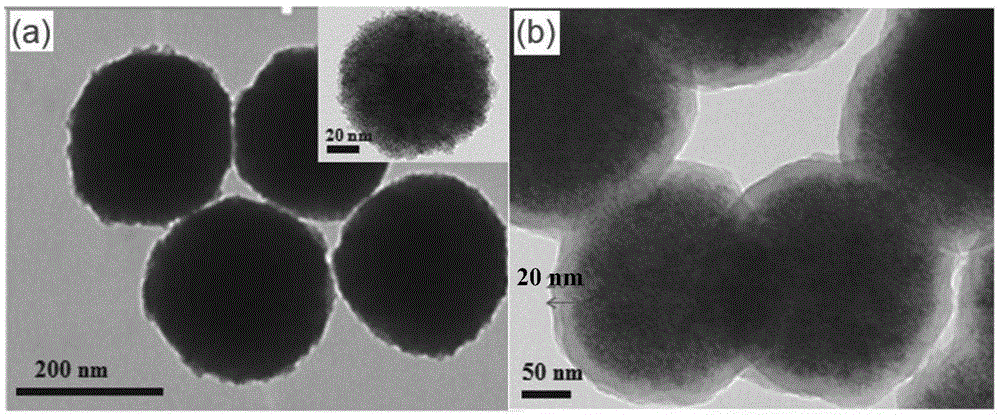

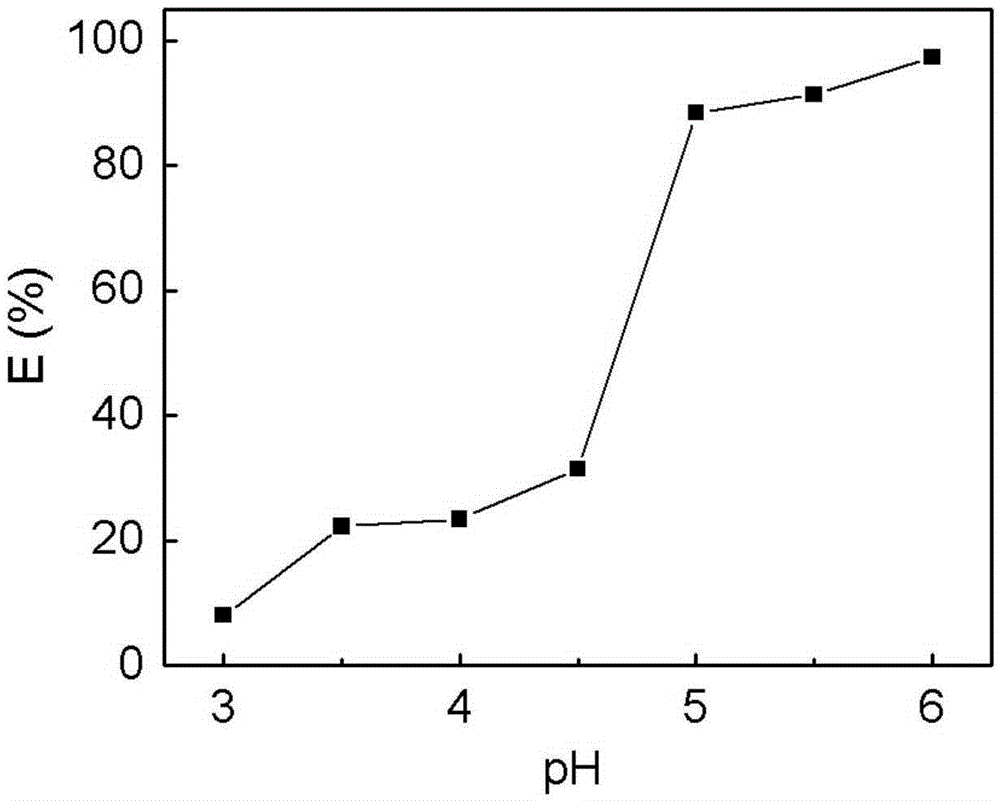

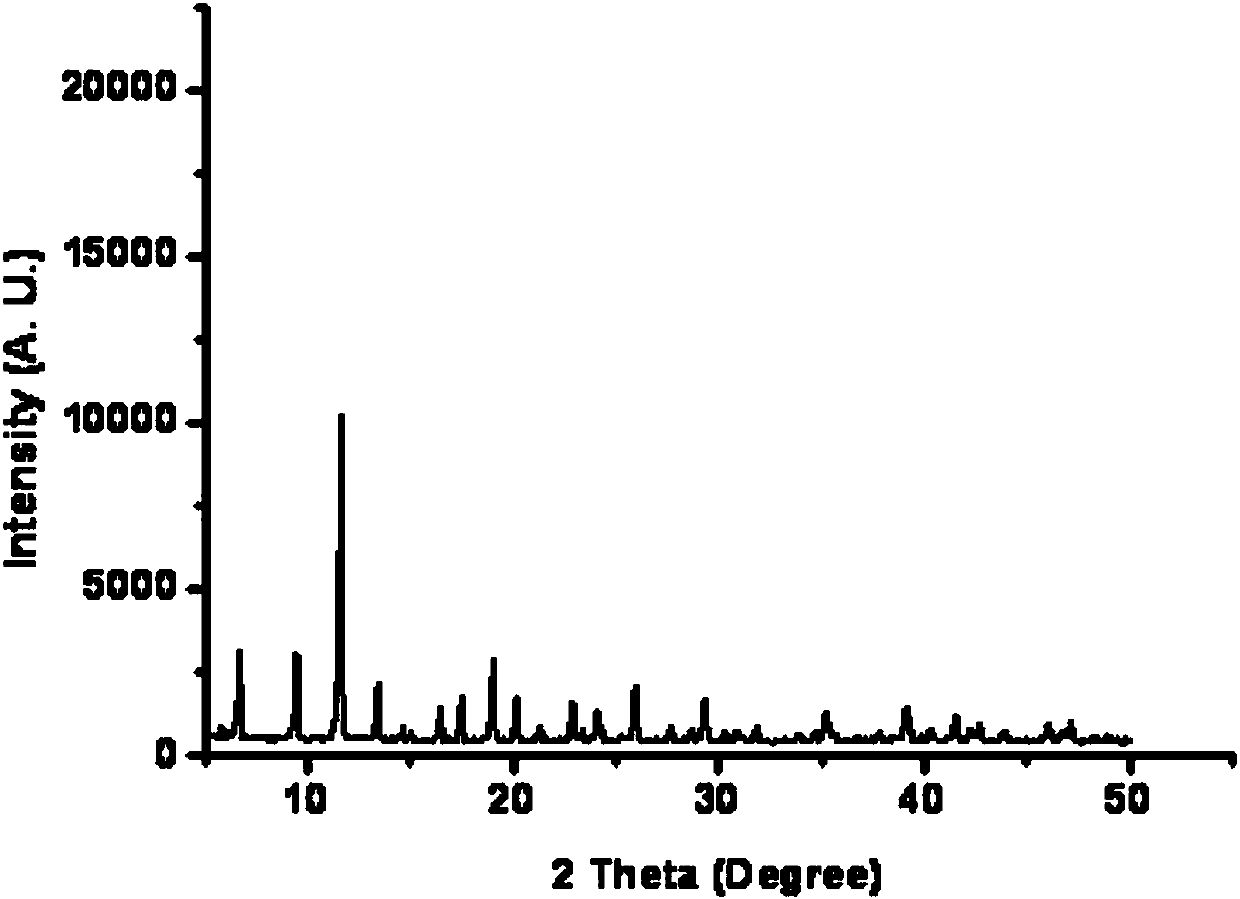

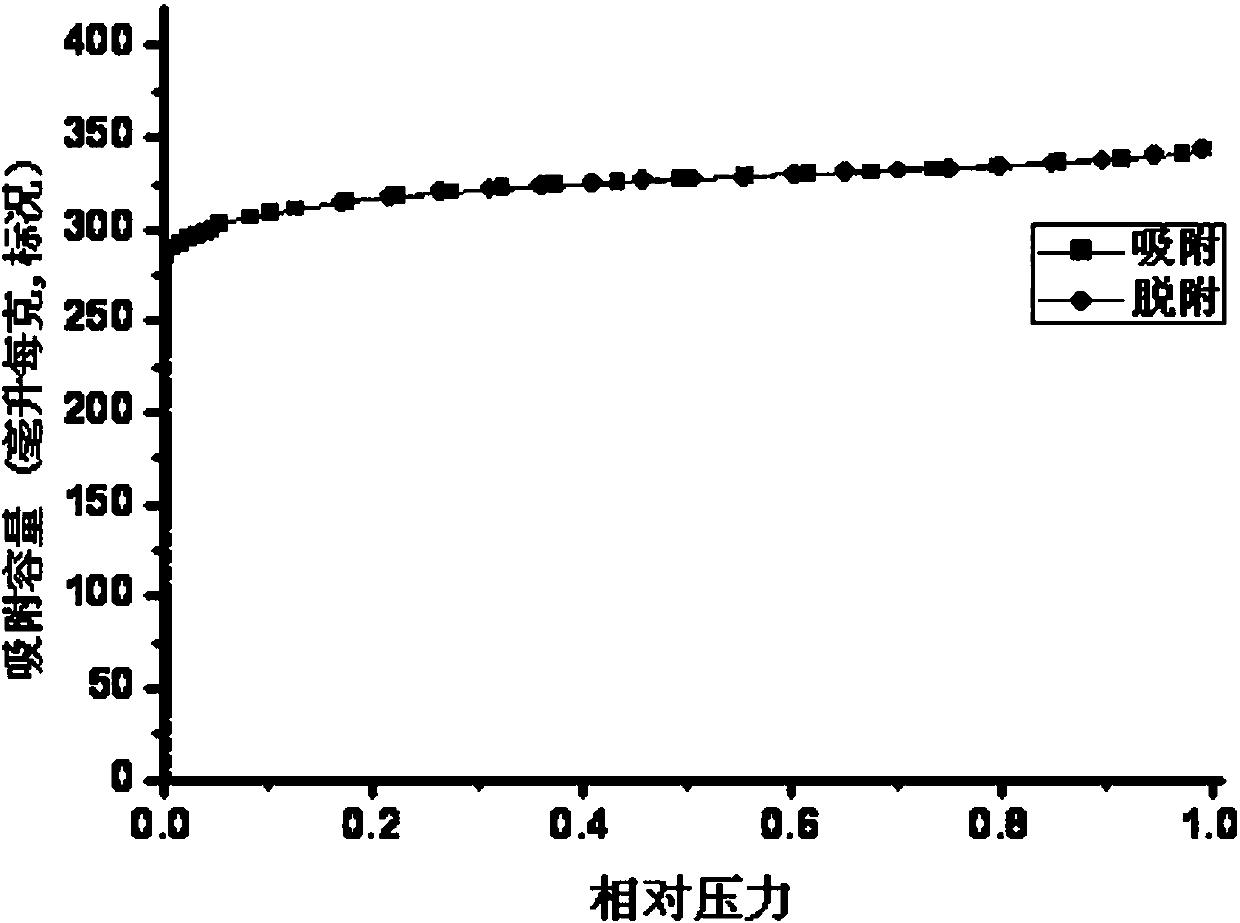

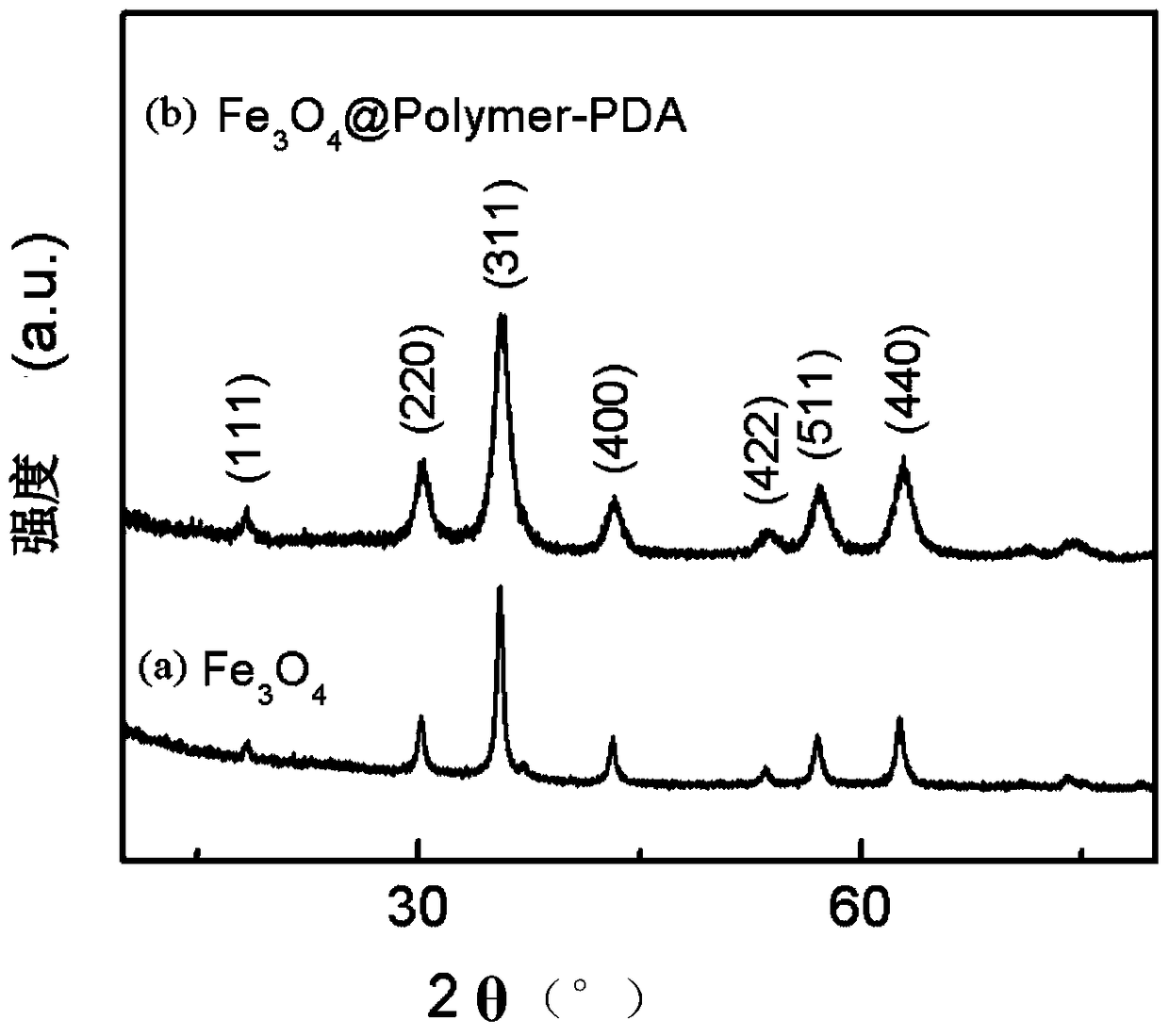

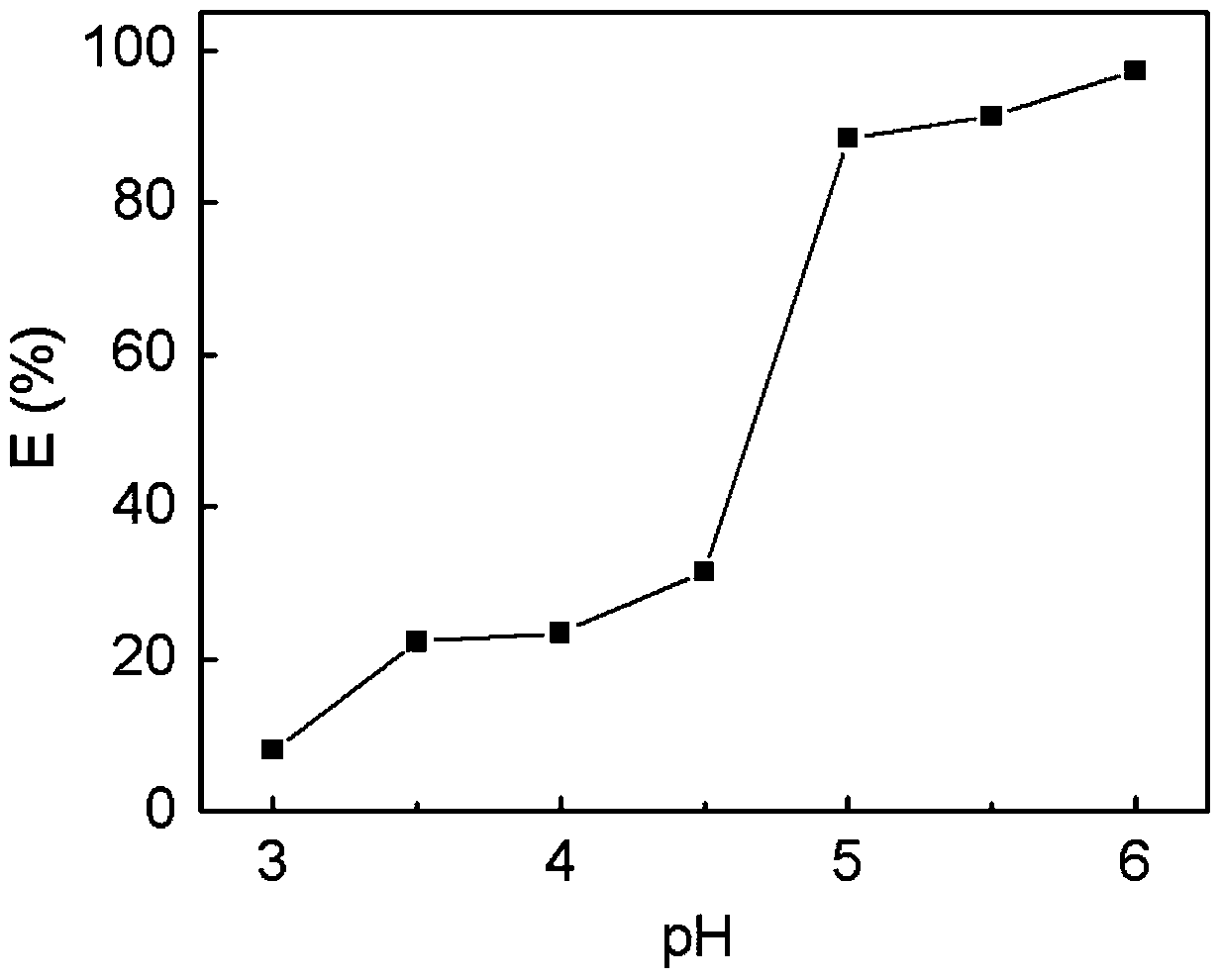

The invention relates to a magnetic bionic adsorbent and an application of the magnetic bionic adsorbent in treating acid wastewater containing uranium. A solvothermal method for preparing Fe3O4 by taking PSSMA (poly (4-styrene sulfonate-copolymer-maleic acid) sodium salt) as a surfactant is improved, grain sizes are uniform, and Fe3O4 magnetic nanoparticles can be synthesized on a large scale; biomolecule dopamine is polymerized in a trihydroxymethyl aminomethane buffer system and coats the surfaces of the Fe3O4 magnetic nanoparticles, and the novel magnetic bionic adsorbent with a core-shell structure is established. The magnetic bionic adsorbent has excellent hydrophilicity and larger specific surface area due to the the polydopamine structure of a shell layer, rich functional groups on the surface of the magnetic bionic adsorbent have high uranium adsorption capacity in a wider acidity range, the magnetic bionic adsorbent has higher uranium adsorption capacity and good selectivity, and uranium adsorbed on the surface of the adsorbent can be easily washed with a 0.1 mol / L (NH4)2CO3 solution and can be recycled conveniently.

Owner:TSINGHUA UNIV

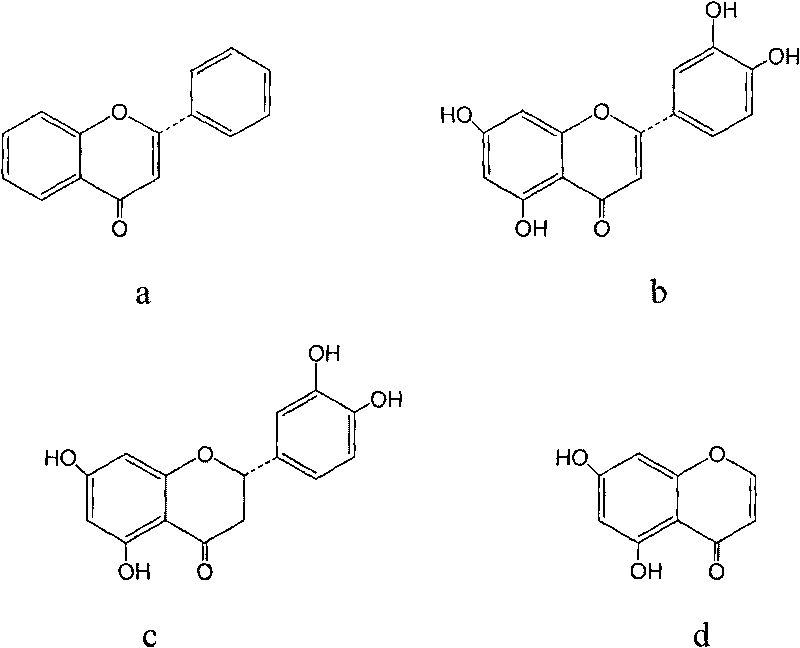

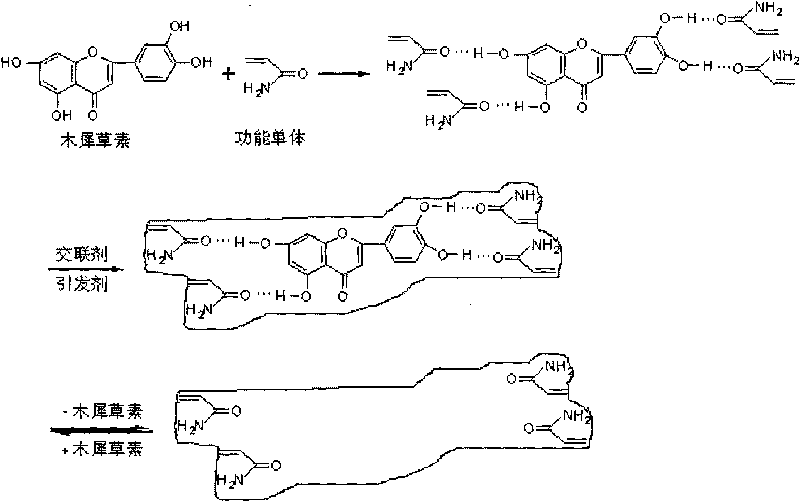

Method for separating and purifying luteolin

InactiveCN101712669AHigh selectivityEasy to separateNervous disorderOrganic chemistryCross-linkFunctional monomer

The invention aims to provide a material for preparing a molecular imprinted polymer by taking luteolin as a template and adopting a molecular imprinting technique method, and a method for separating and purifying the luteolin in a natural product, and belongs to the field of separation and purification of effective components from the natural product. The method comprises the following steps: (1) crude extraction, namely sequentially washing, drying, crushing and sieving peanut shells, extracting the peanut shell powder with 70 percent ethanol time by time under the assistance of ultrasonic waves, and concentrating and drying the extract; (2) preparation of the polymer, namely weighing the pure luteolin, a functional monomer, a cross-linking agent and an initiating agent in proportion, dissolving the materials in a solvent, performing ultrasonic processing, degassing and polymerization on the solution to obtain the block polymer, and sequentially grinding, sieving and eluting the block polymer to obtain the molecular imprinted polymer of the luteolin; and (3) purification, namely loading the prepared molecular imprinted polymer into a solid-phase extraction column, loading the crude extract, washing off the luteolin left on the column after removing impurities by eluting, concentrating and drying the luteolin to obtain the pure product of the luteolin.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

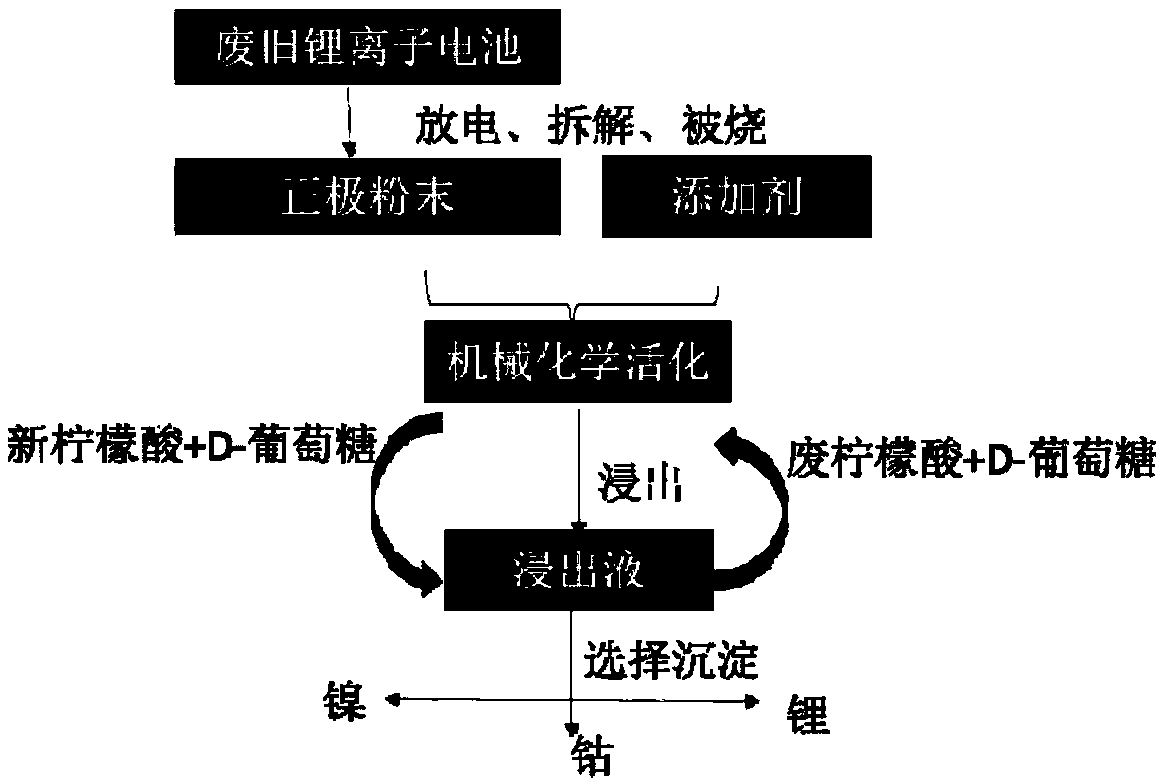

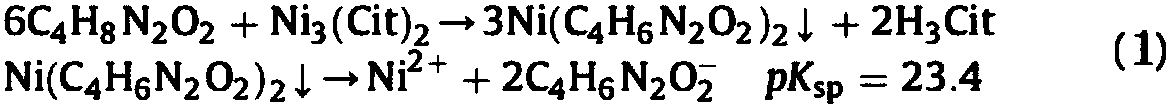

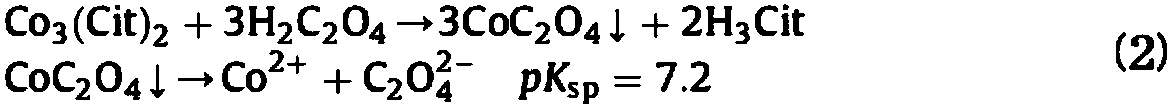

Method for recycling high-value-added metals from waste nickel-cobalt-manganese lithium ion batteries

InactiveCN108913873AConducive to enhanced leachingParticle refinementWaste accumulators reclaimingProcess efficiency improvementAdhesiveManganese

The invention relates to a method for recycling high-value-added metals from waste nickel-cobalt-manganese lithium ion batteries and belongs to the technical field of recovery of lithium batteries. The method comprises the following steps: (1) thoroughly discharging waste nickel-cobalt-manganese batteries, disassembling and sorting out positive powder, and carrying out heat treatment on the positive powder to remove impurity components such as conductive agents and adhesives in the positive powder; (2) mixing the positive powder subjected to heat treatment with active additive according to a ratio, then mechanically and finely grinding so as to carry out machine-chemical synergistic activation of the positive powder; and (3) mixing the activated positive powder with citric acid-D glucose leachate leaching agent, then carrying out leaching reaction and precipitating nickel, cobalt, manganese and lithium in the filtrate to obtain the high-value-added metals. According to the method, citric acid in the citric acid-D glucose leachate can be recycled after extracting the metal elements; high consumption of the leachate is avoided; the leaching efficiency is improved; the recycling costis reduced.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

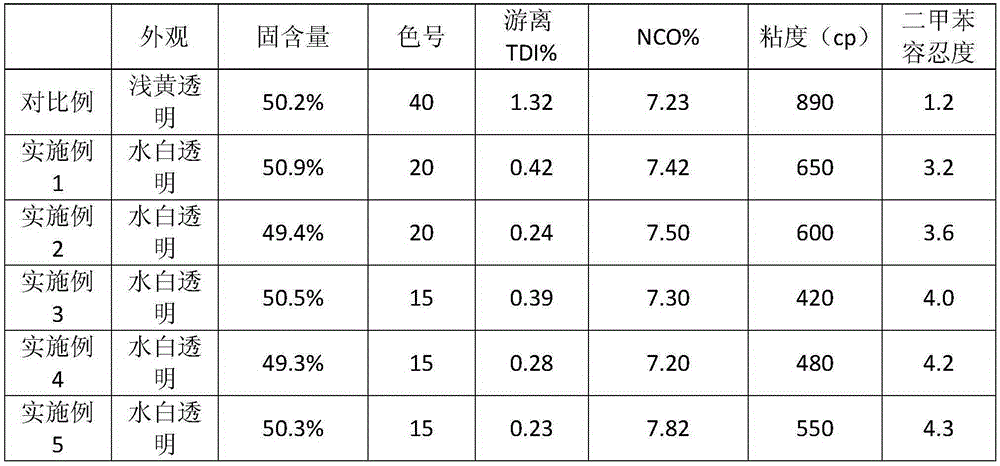

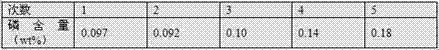

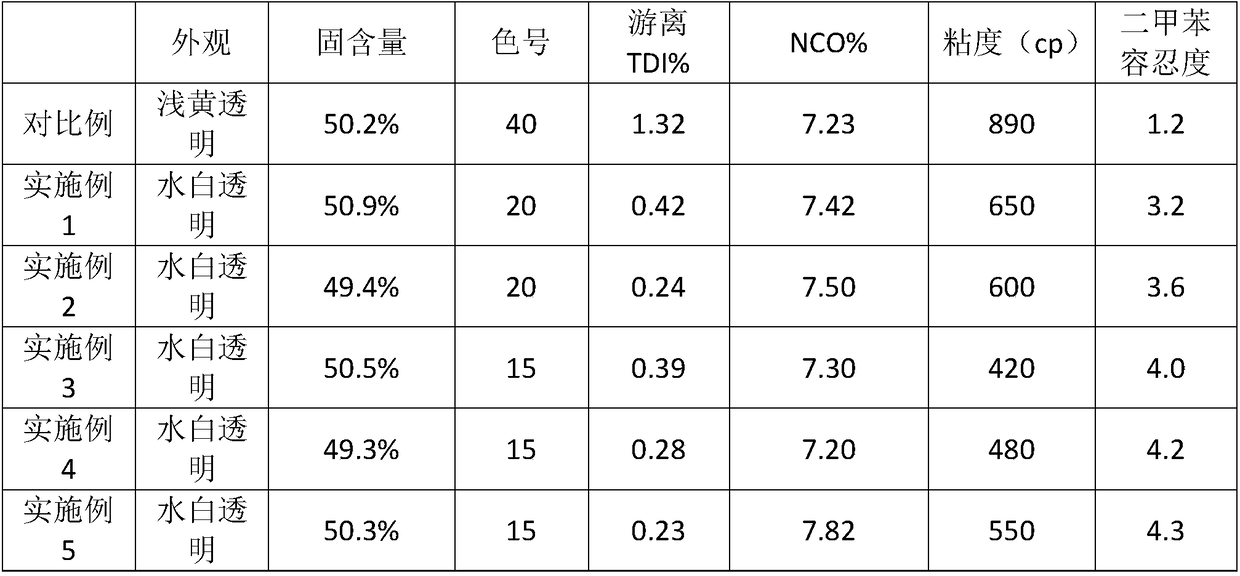

Low-free high-compatibility toluene diisocyanate trimer curing agent and preparation method thereof

ActiveCN105315433AFacilitated DiffusionReduce contentPolyurea/polyurethane coatingsToluene diisocyanateAntioxidant

The invention discloses a low-free high-compatibility toluene diisocyanate trimer curing agent and a preparation method thereof. The preparation method comprises the following steps: under nitrogen protection, putting a toluene diisocyanate monomer, a solvent and an antioxidant into a reaction vessel; controlling the reaction temperature to be 10-50 DEG C at an earlier stage; adding a catalyst in batches when NCO% is 12-14wt% and 10-11wt% and reaction is started; when NCO is 9.3-10wt%, adding the residual catalyst and controlling the temperature to be 50-100 DEG C; when NCO% is 8.0-9.3wt%, adding a polymerization inhibitor, reacting for 0.5-1 h, adding a component A, reacting for 2-4 h, adding a component B, reacting for 1-2 h, stopping reaction, cooling to room temperature and discharging materials so as to obtain the toluene diisocyanate trimer curing agent with free TDI less than 0.5%, xylene tolerance larger than 3, light color, quick drying and stable performance finally.

Owner:SOUTH CHINA UNIV OF TECH

Formula of multifunction fuel and its production process

InactiveCN1513954ALow costWide range of raw materialsLiquid carbonaceous fuelsChemical reactionSecondary component

An environment protection type multifunctional fuel is prepared from 7 primary components including light hydrocarbon, light oil, gasoline, diesel oil, etc and 20 secondary components including sodium hydroxide, water alcohol, hydrogen peroxide, etc. which are divided into 4 groups which take part in chemical reactions to generate cosolvent, oxygen increaser, combustion aid, smoke reducing agent, etc.

Owner:张云

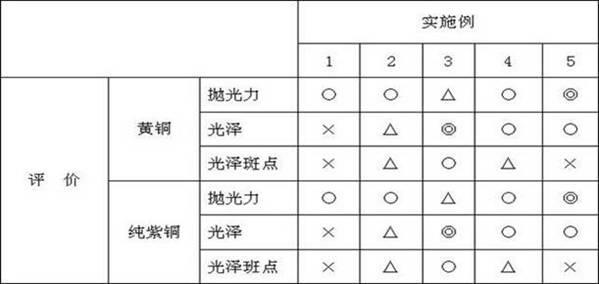

Polishing solution for processing surfaces of copper and copper alloy by replacing copper pickling process

The invention relates to a polishing solution for processing surfaces of copper and copper alloy by replacing a copper pickling process. The polishing solution consists of the following components in percentage by volume: 10 to 40 percent of hydrogen peroxide, 2 to 5 percent of organic brightening agent, 0.8 to 2.4 percent of concentrated sulfuric acid, 3 to 8 percent of hydrogen peroxide stabilizing agent and the balance of water. The polishing solution does not comprise chromic acid, nitric acid or hydrochloric acid, smoothens the surface of the copper or the copper alloy through chemical polishing, and ensures complete luster on the surface subjected to chemical polishing.

Owner:WENZHOU AOYANG METAL SURFACE TREATMENT

Process method for extracting and separating rear earth without saponification

InactiveCN101709392AAvoid heavy consumptionAvoid it happening againProcess efficiency improvementRare earthWastewater

The invention relates to a process method for extracting and separating rear earth without saponification, which is characterized by adding water to dilute the acidity of an extraction reaction solution in extraction technological process. Compared with a conventional process, the method uses the dilution with water to replace the saponification with alkali substances in the extraction technological process. The method avoids the large consumption of the alkali substances and reduces the production cost. Particularly, the method avoids the generation of a great deal of waste water containing NH4+, and achieves cleanness, environmental protection and recycling utilization from sources.

Owner:全南县新资源稀土有限责任公司

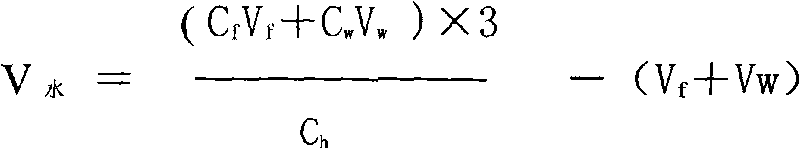

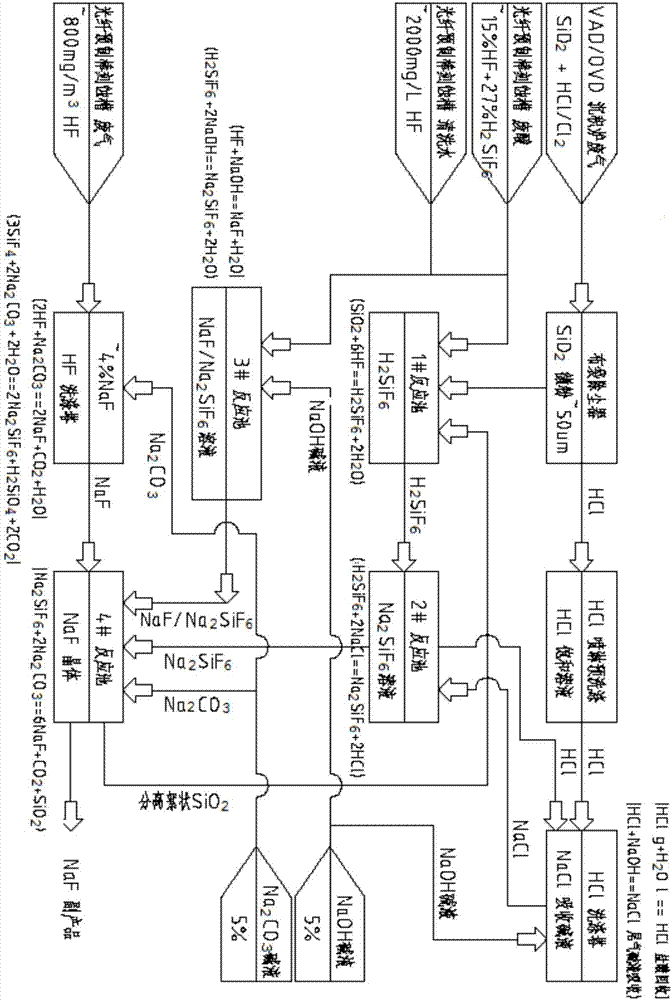

Waste treatment method for gas-phase method quartz product manufacturing process and waste treatment method for optical fiber perform manufacturing process

ActiveCN105753220ASolve the problem that fluoride ion is difficult to reach the standardAvoid heavy consumptionWater contaminantsDispersed particle separationIonZero emission

The invention discloses a waste treatment method for a gas-phase method quartz product manufacturing process and a waste treatment method for an optical fiber perform manufacturing process.The waste treatment method for the gas-phase method quartz product manufacturing process includes: adding SiO2 micropowder into a first reaction vessel; adding waste liquid generated by quartz etching treatment into the first reaction vessel; allowing reaction of H2SiF6 with NaCl to generate Na2SiF6 and HCl; allowing reaction of NaOH with HF in the waste liquid generated by quartz etching treatment to generate NaF and water, and allowing reaction of NaOH with H2SiF6 in the waste liquid generated by quartz etching treatment to generate Na2SiF6 and water; adding the Na2SiF6 generated in a second reaction vessel and NaF and Na2SiF6 generated in a third reaction vessel into a fourth reaction vessel, adding Na2CO3 into the fourth reaction vessel, and allowing reaction of the Na2SiF6 with the Na2CO3 to generate NaF, SiO2 and CO2.The comprehensive treatment process can completely substitute for an original CaF2 neutralization and sedimentation process, investment of a wastewater treatment system is reduced, fluorine ion residues are avoided, and system zero emission can be realized.

Owner:HAWK SHANGHAI ENVIRONMENTAL TECH

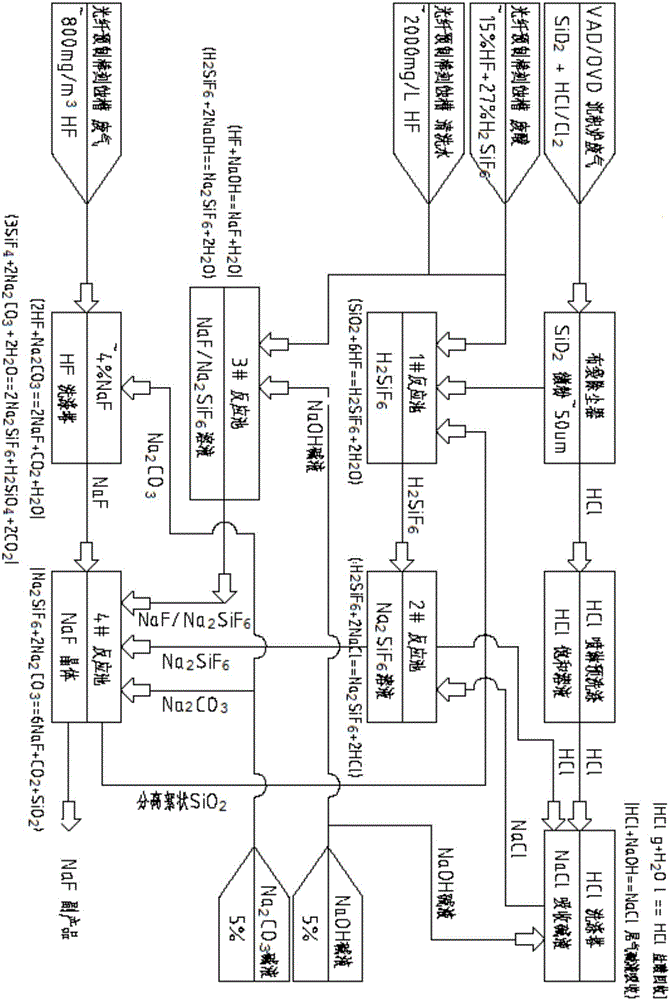

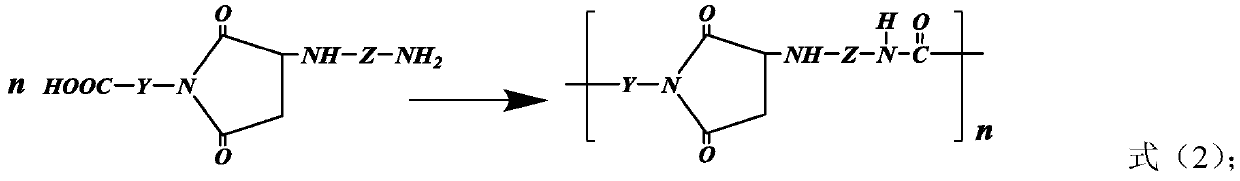

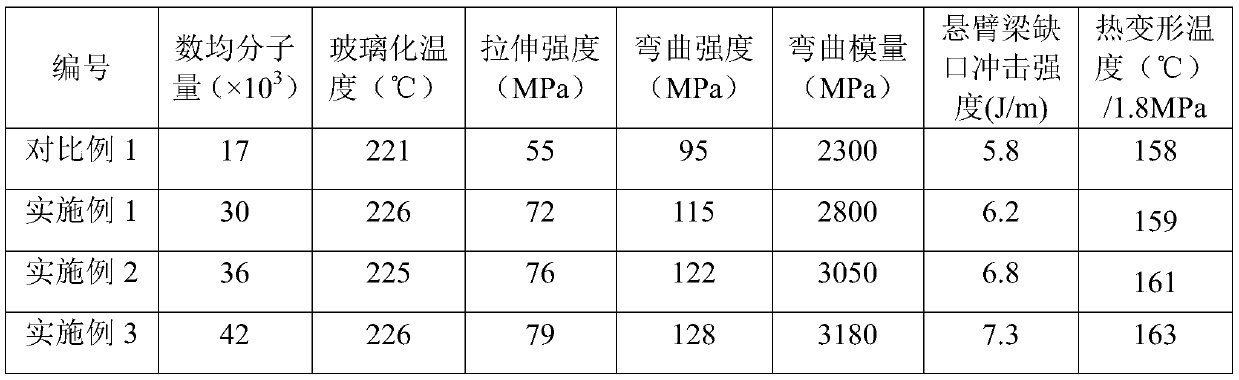

Polyamideimide and preparation method thereof

InactiveCN109824897AImprove mechanical propertiesSimple chemical structureEquivalence ratioCarboxylic acid

The invention provides a polyamideimide preparation method. The method includes: adding aromatic diamine, maleimide carboxylic acid and organic alkaline catalysts into a non-proton nitrogen-containingpolar organic solvent, stirring, heating to perform reflux reaction, drying after reaction to obtain an amino acid powder monomer with an imide group; adding the amino acid powder monomer, a hypophosphite catalyst and deionized water into a high-pressure polymerization reactor to realize self-condensation polymerization, completing the reaction to obtain suspension of a polyamideimide prepolymer,drying, performing vacuum solid-phase viscosity increasing to obtain polyamideimide in different molecular weights. The method is simple in process route, effective in organic solvent recovery, low in cost, free of equivalence ratio control of monomers and the like and easy to industrialize. The invention further provides polyamideimide prepared according to the method. The polyamideimide has great forming processing characteristics and has advantages of high strength, high modulus, high heat resistance and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

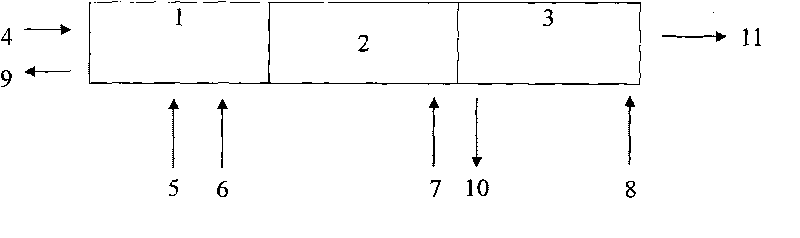

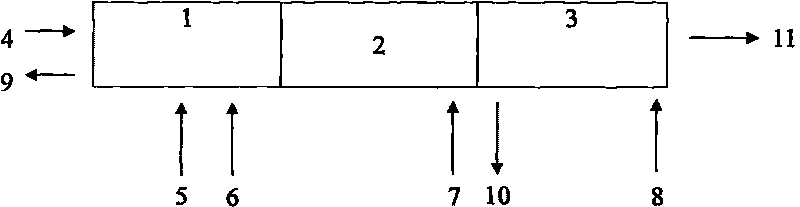

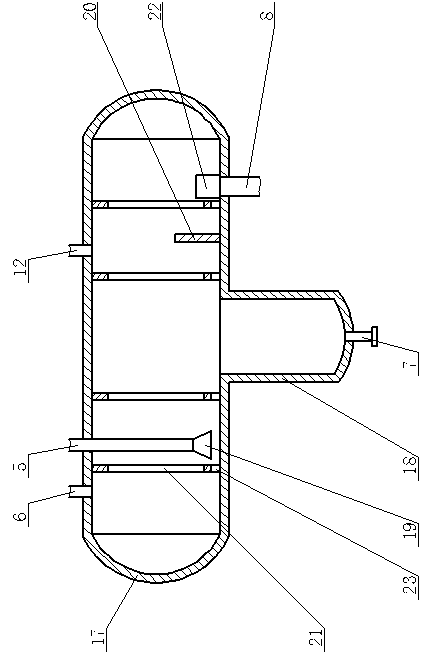

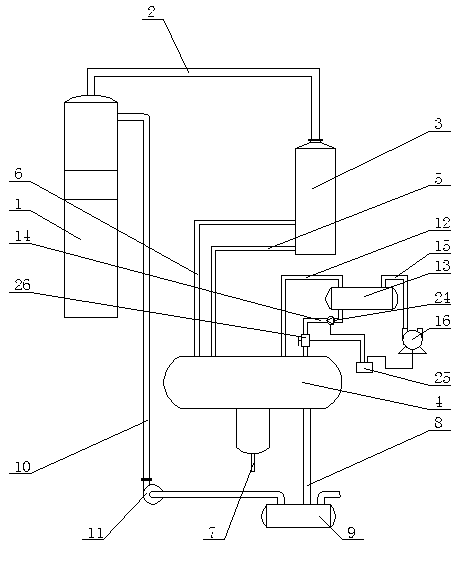

System for producing light benzene by performing negative pressure debenzolization on rich oil

ActiveCN102796571ALow costAvoid heavy consumptionDistillation regulation/controlCombustible gas purificationBoiling pointBenzene

The invention provides a system for producing light benzene by performing negative pressure debenzolization on rich oil. The system comprises a debenzolization tower, wherein the top of the debenzolization tower is communicated with a light benzene condensation cooler through a light benzene steam pipeline, the light benzene condensation cooler is communicated with a light benzene return tank through a cooling liquid introducing pipe and a pressure balancing pipe, the light benzene return tank is connected with a light benzene return groove through a light benzene discharge pipe, the light benzene return groove is connected with the debenzolization tower through a light benzene return pipe, the light benzene return tank is provided with a non-condensable gas discharge pipe, the non-condensable gas discharge pipe is communicated with a tubular heat exchanger, a negative pressure pipe is arranged on the tubular heat exchanger, and the negative pressure pipe is communicated with a vacuum pump. The system disclosed by the invention can change ordinary pressure operation to negative pressure operation in a rich oil debenzolization distillation process, be conducive to reducing the distillation boiling point of the light benzene at the top of the tower, reduce the load of the light benzene condensation cooler, realize a smaller amount of separated water from the light benzene, eliminate the need of adopting multiple devices to separate the separated water from the light benzene, be conductive to lowering the cost of the devices, avoid great consumption of steam resources and be conductive to reducing environmental pollution.

Owner:JIGANG INT ENG & TECH CO LTD

Slurry state synthetic method for porous composite framework material

InactiveCN107674088ANarrow particle size distributionWide particle size distributionGroup 1/11 organic compounds without C-metal linkagesOther chemical processesMass ratioSynthesis methods

The invention belongs to the technical field of preparation of porous composite materials, and provides a slurry state synthetic method for a porous composite framework material. The mass ratio of a solvent to a solid reactant is controlled, so that the reactant is at different saturations, an inorganic-organic composite framework material is obtained through heating in a sealed container, and thecrystal size and distribution of the composite framework material are regulated and controlled. Under a room temperature, an inorganic metal source is dispersed into the solvent, and then mixed witha polycarboxylic acid organic compound to form a slurry material, and the slurry material is sealed in a self-pressurized reaction kettle, the obtained material is heated to 70-170 DEG C, a reaction is performed for 0.5-240 hours, drying is performed at the room temperature, and therefore the porous composite framework material is obtained. According to the invention, the crystal size is controllable, and the method provides a novel synthetic route for controlling the particle size of the composite framework material; the yield is higher, washing is not needed, the operating costs are low, theoperation is easy, the emission is zero, the method is green, environmentally friendly, economical and practicable, and the large-scale intensive production is easy to realize; and the obtained large-particle composite framework material has a higher adsorption capacity in the gas adsorption aspect.

Owner:TAIYUAN UNIV OF TECH

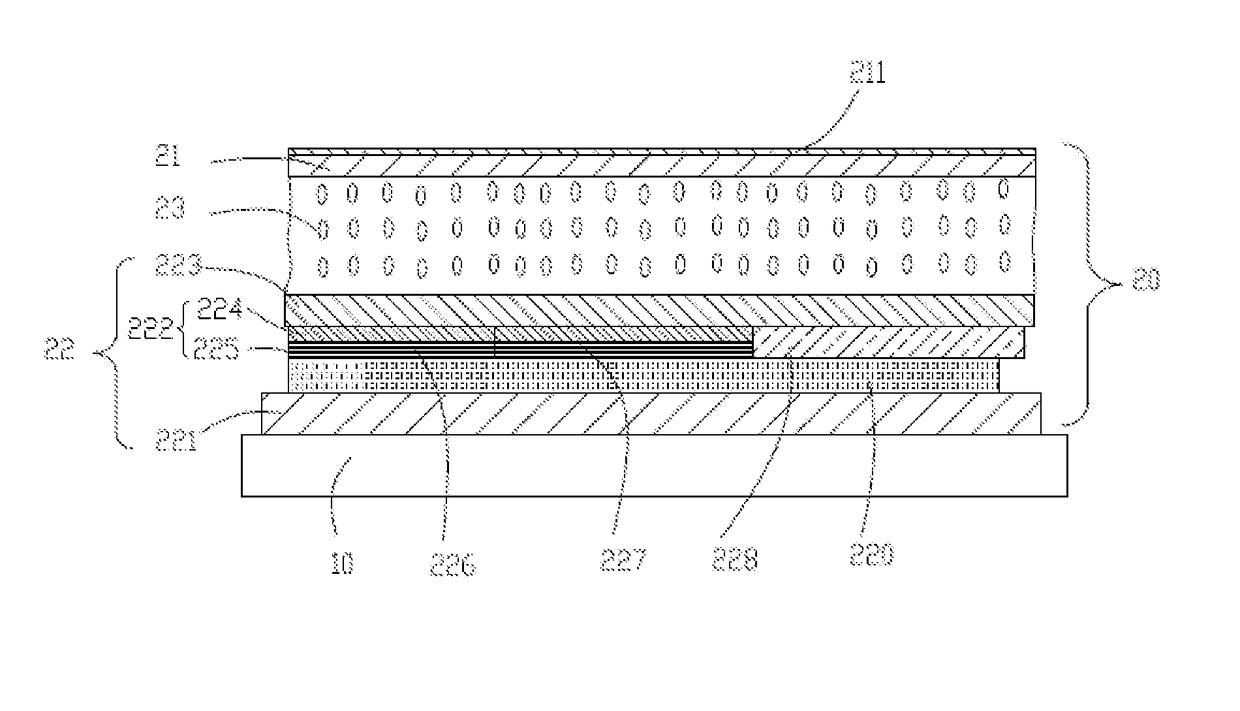

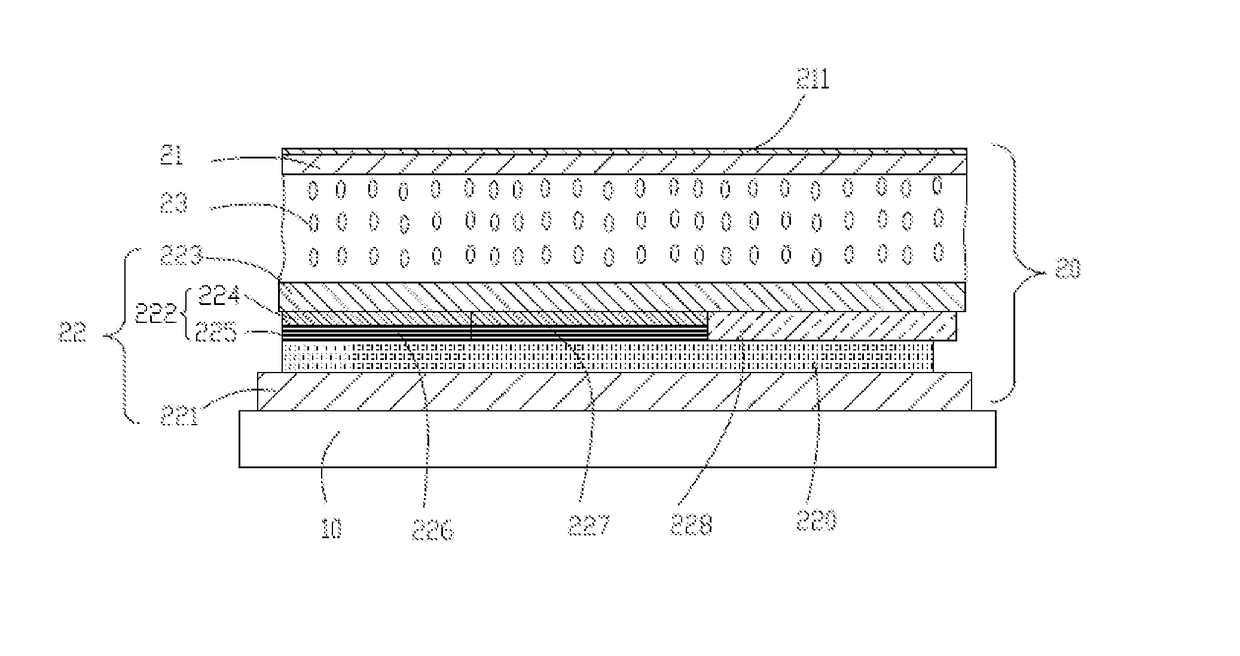

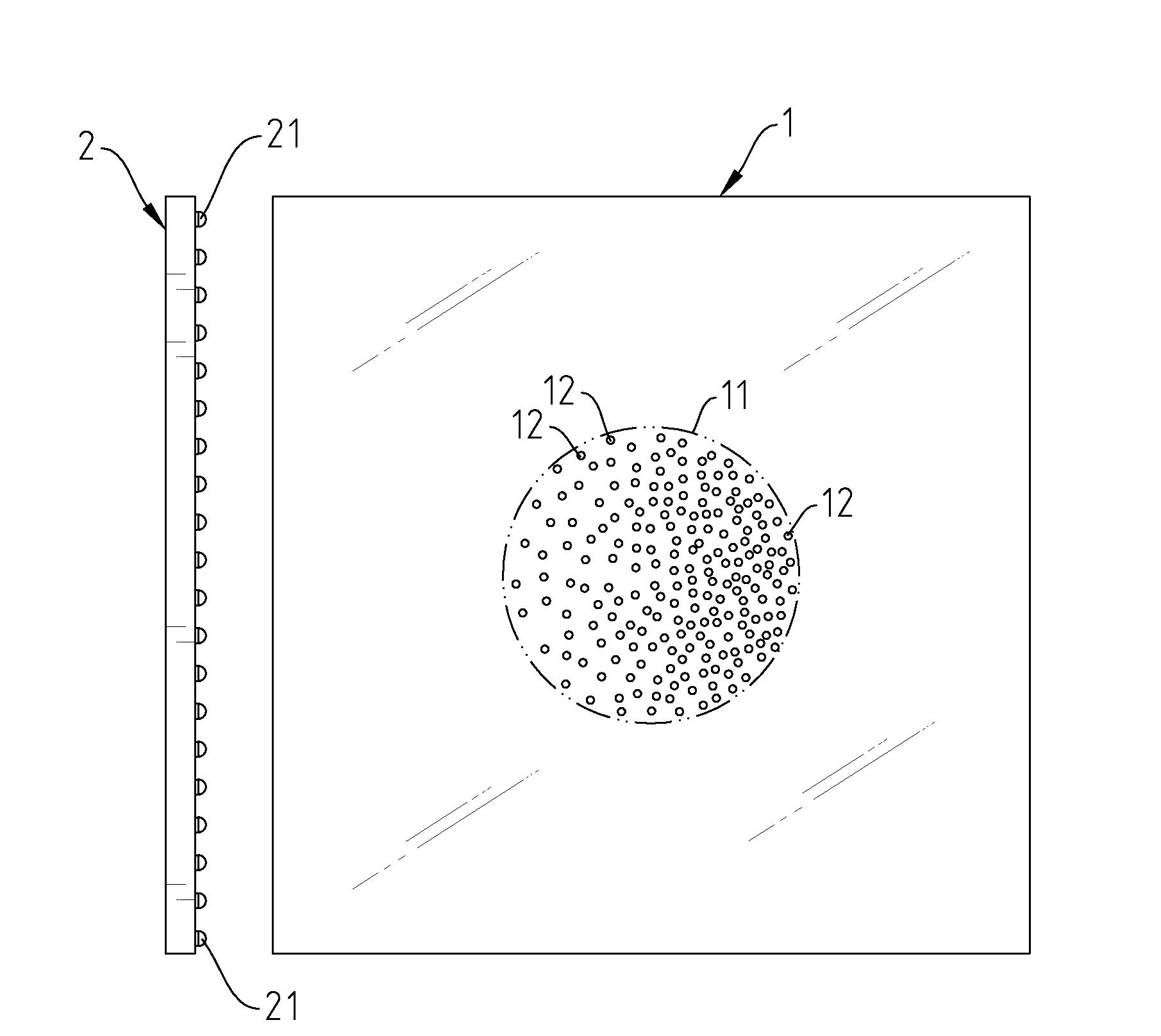

Liquid crystal display device and electronic equipment

ActiveUS20170227819A1Improve photosynthetic efficiencyAvoid absorptionNon-linear opticsLiquid-crystal displayColor film

A LCD device comprises a backlight module and a liquid crystal panel, where the liquid crystal panel includes a color film substrate, an array substrate sandwiched between the color film substrate and the liquid crystal layer of the array substrate. The light source is blue; the array substrate includes a glass substrate and a color layer provided on the glass substrate and a polarized layer laminated with color layer. The polarized layer is disposed adjacent to the liquid crystal layer. The color layer includes the blue light filter layer and the color unit layer which is laminated on a blue light filter layer and back of the surface of the polarized layer The color unit layer includes several color units, each of the units includes a red color quantum rod layer, a green quantum rod layer and a transparent color filter layer. The present invention also discloses an electronic equipment.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

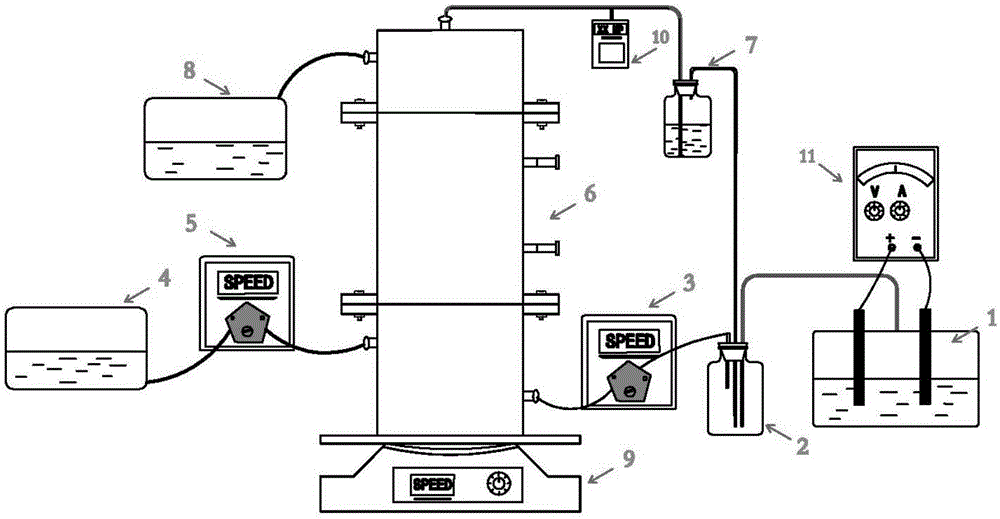

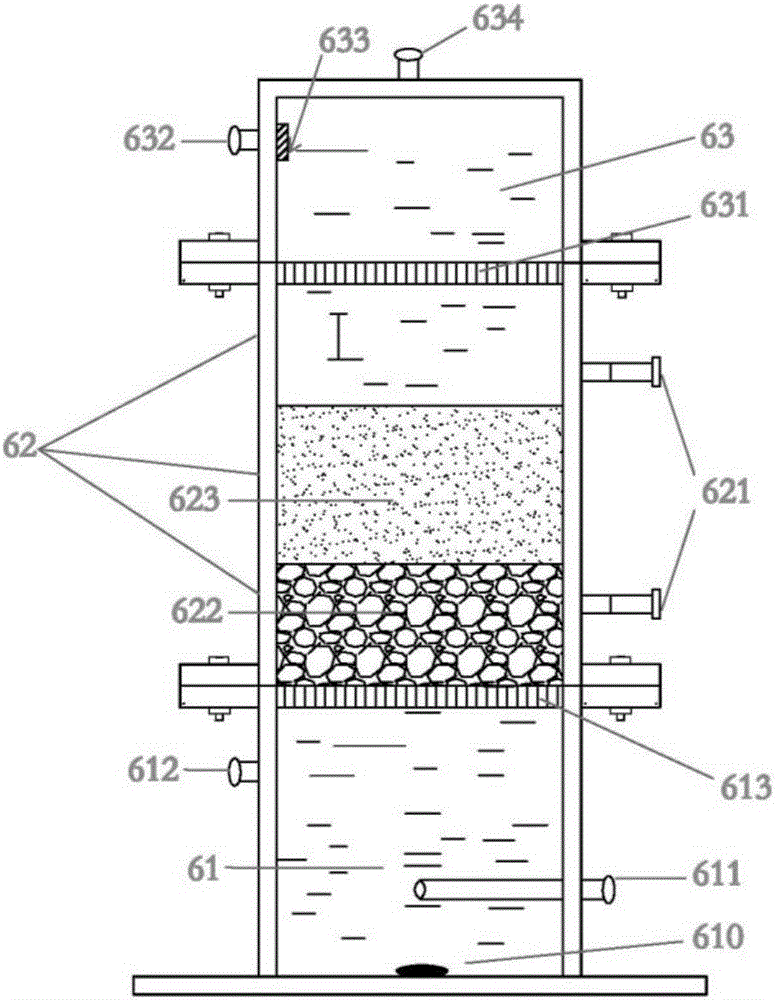

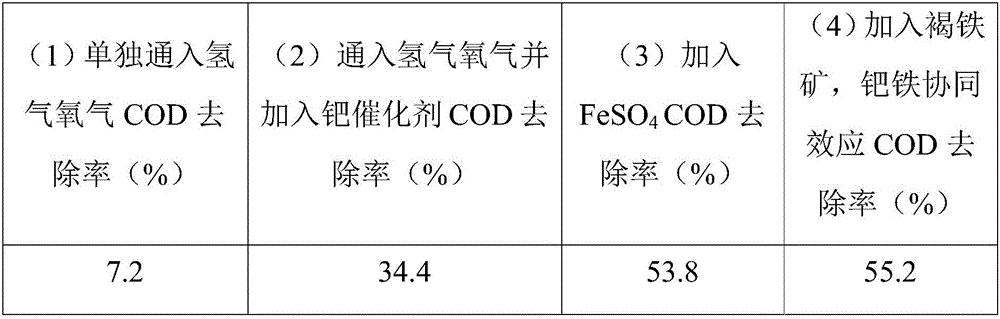

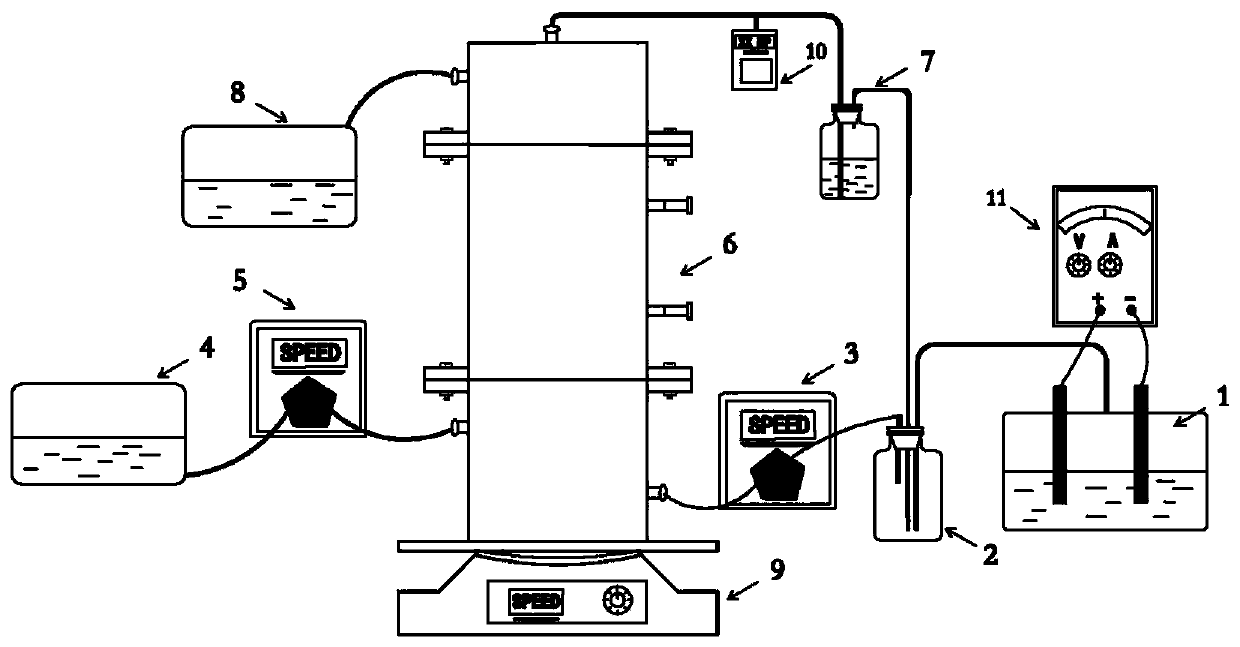

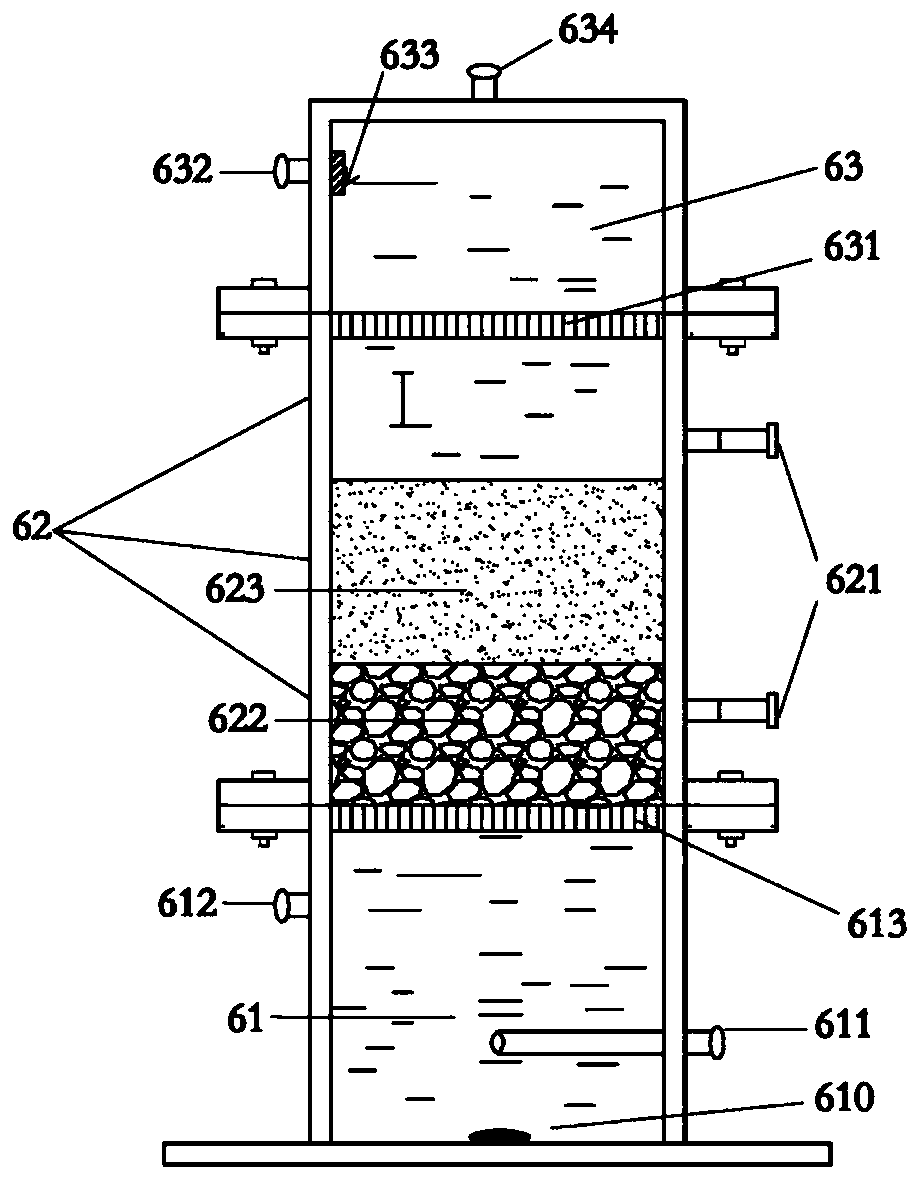

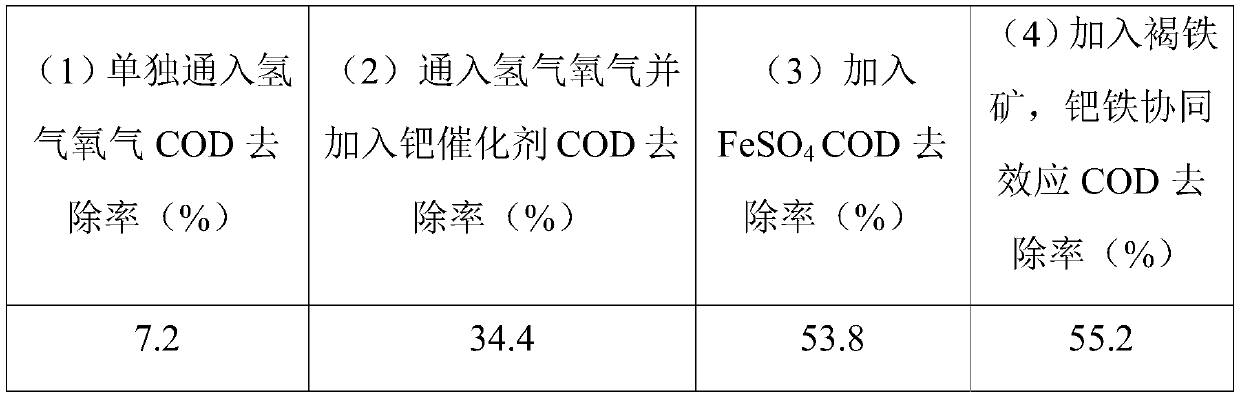

Landfill leachate treatment method, device and system

ActiveCN106630100AEfficient degradationHelp break downWater treatment compoundsWater contaminantsPalladium catalystOxygen

Owner:HUAZHONG UNIV OF SCI & TECH

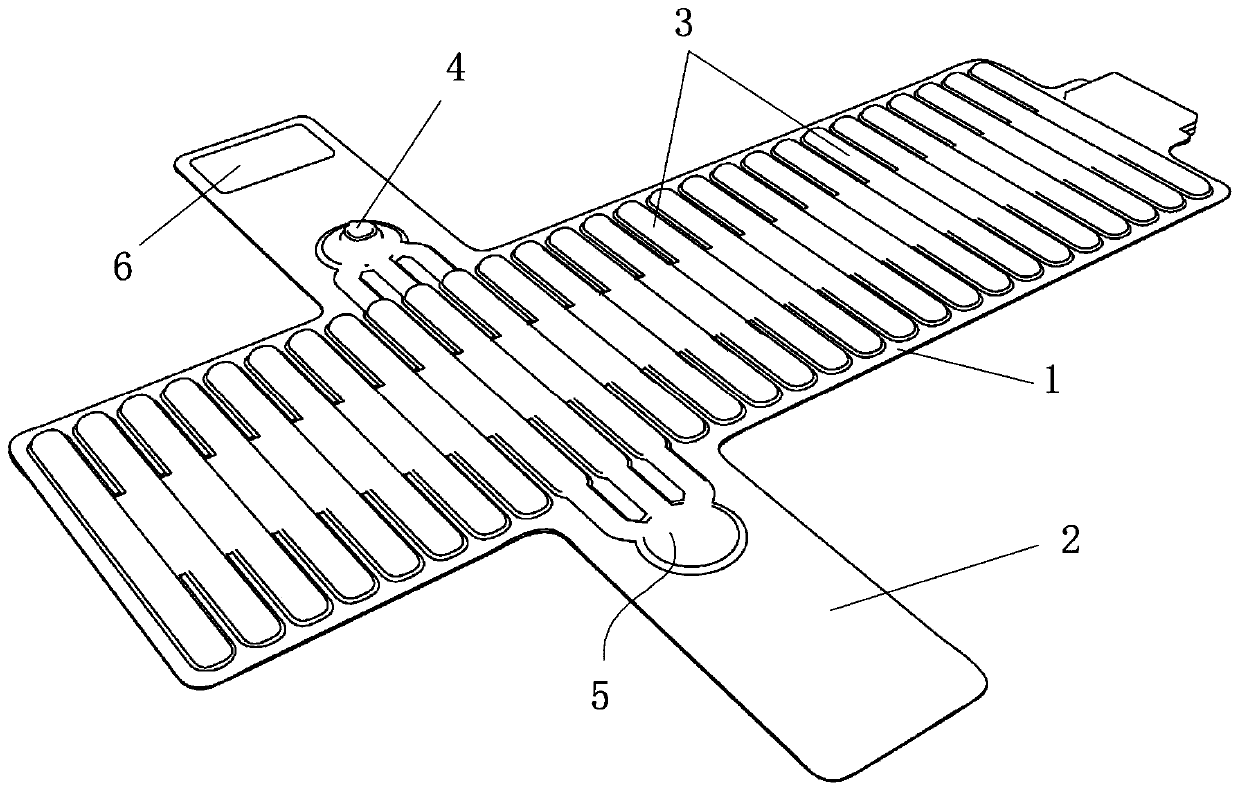

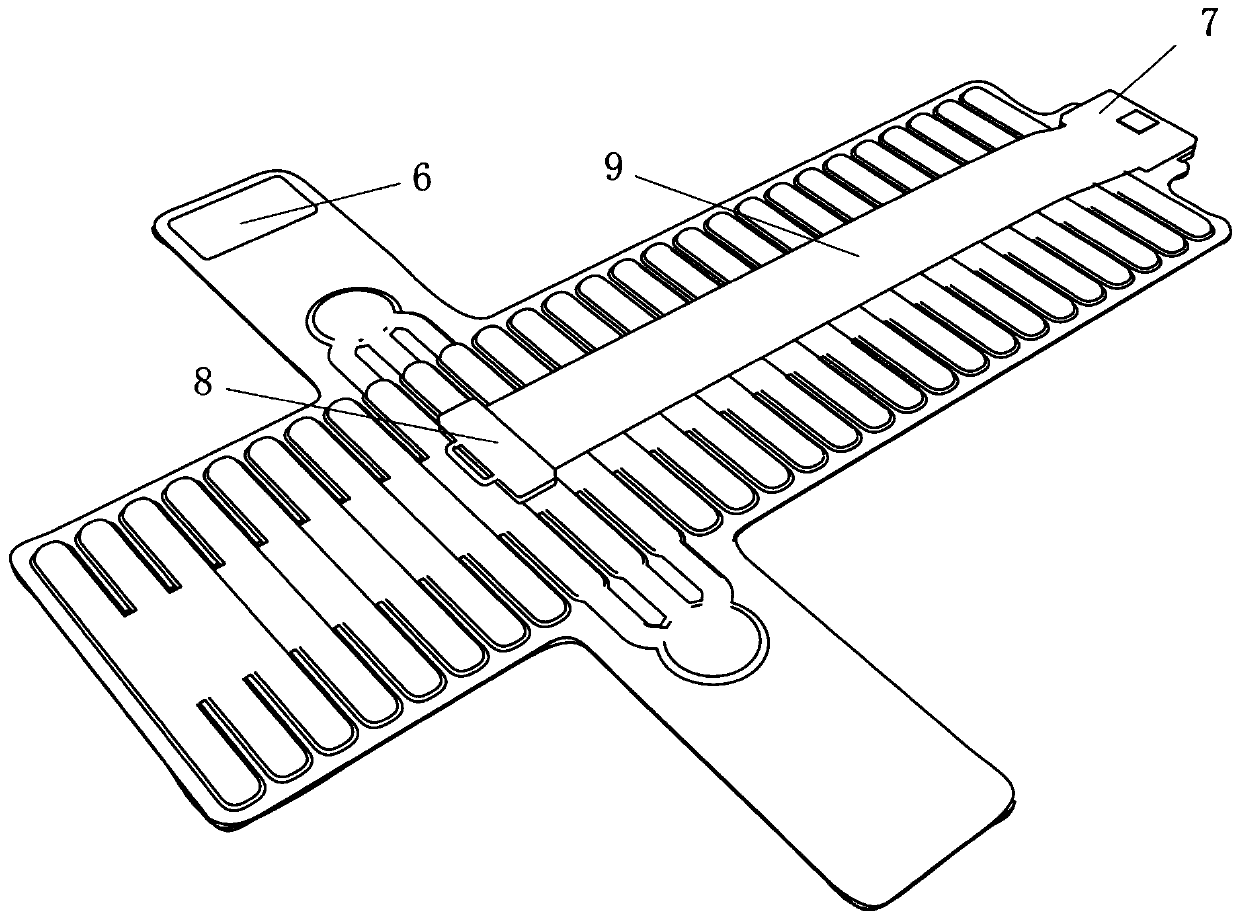

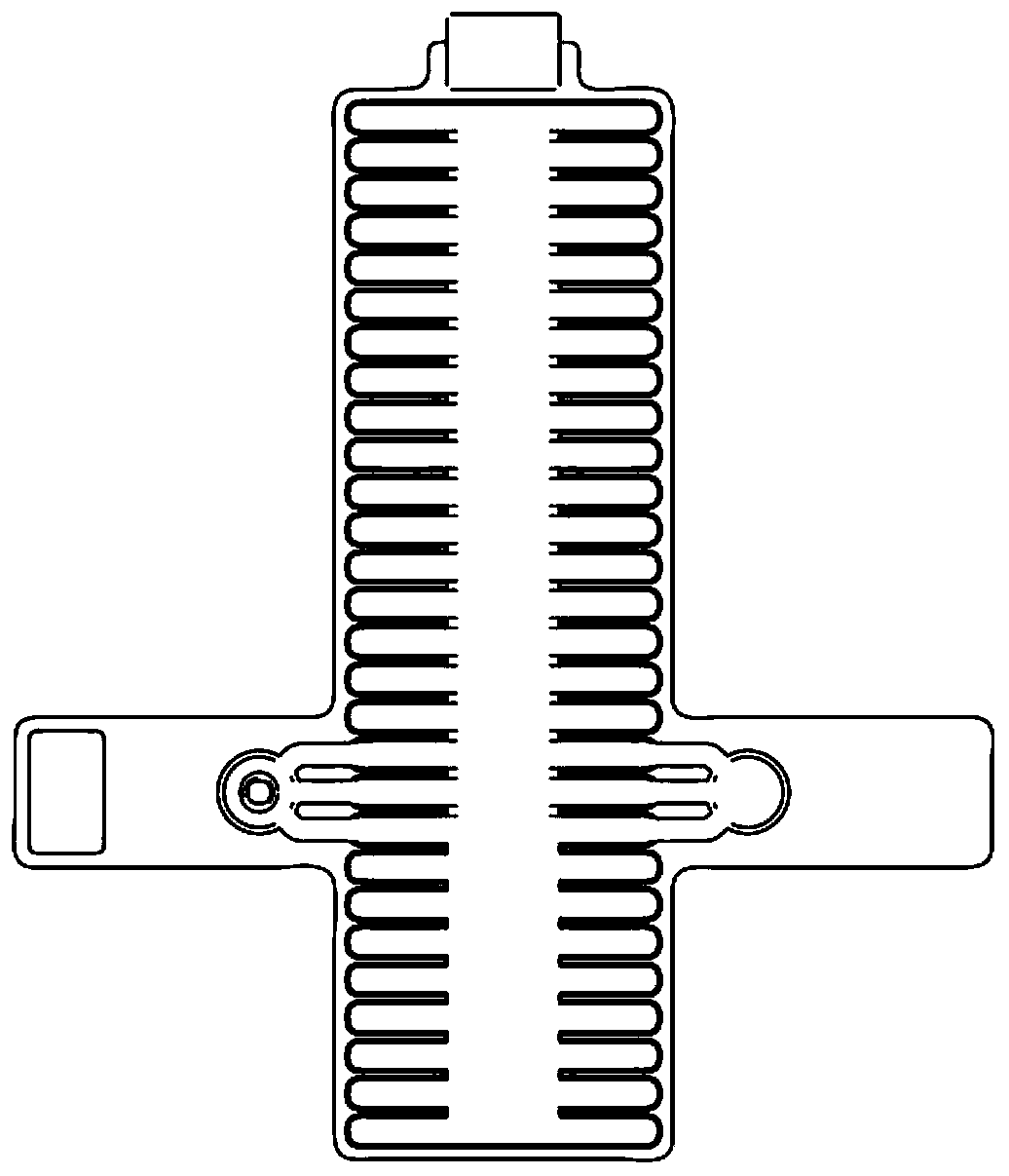

Inflatable type environment-friendly express bag with intelligent lock

PendingCN109809041AWaste controlEase of useContainers to prevent mechanical damageLocking devicesEngineeringAir cushion

The invention discloses an inflatable type environment-friendly express bag with an intelligent lock. The inflatable type environment-friendly express bag comprises a first air cushion and a second air cushion which are used for wrapping an object, a plurality of buffer air bags, an air inflation valve mouth used for carrying out rapid inflation, a side face buffer block used for protecting the object, a magic paste used for sticking and fixing the object horizontally and a lock buckle used for fixing the object longitudinally. When the inflatable type environment-friendly express bag with theintelligent lock is used, firstly, the express bag is inflated with air through the air inflation valve mouth, then the object is placed on the front face of the express bag (the joint between the first air cushion and the second air cushion), with that, the two ends of the second air cushion are lifted up correspondingly and are put on the top of the object, a male surface and a female surface of the magic paste are made to be fitted and pasted tightly, with that, the short end of the first air cushion is lifted up and is fitted to the object, finally, the long end of the first air cushion is wrapped up surrounding the object together with a locking band, a buckle body is locked into a lock body after tight wrapping, and express packaging operations are finished. The inflatable type environment-friendly express bag with the intelligent lock further has the advantages of being simple in structure, convenient to operate and easy to carry out.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

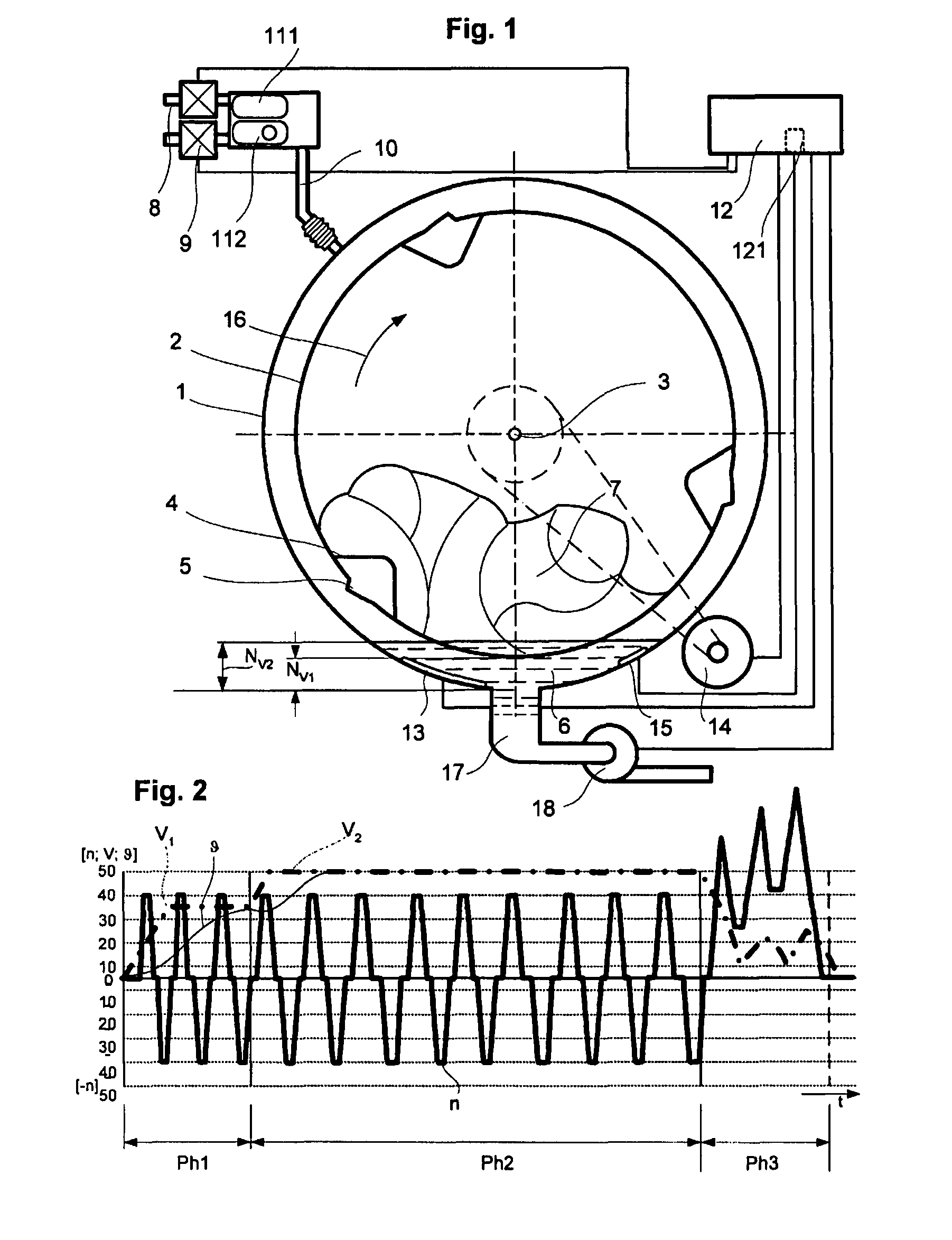

Method for impregnating textiles

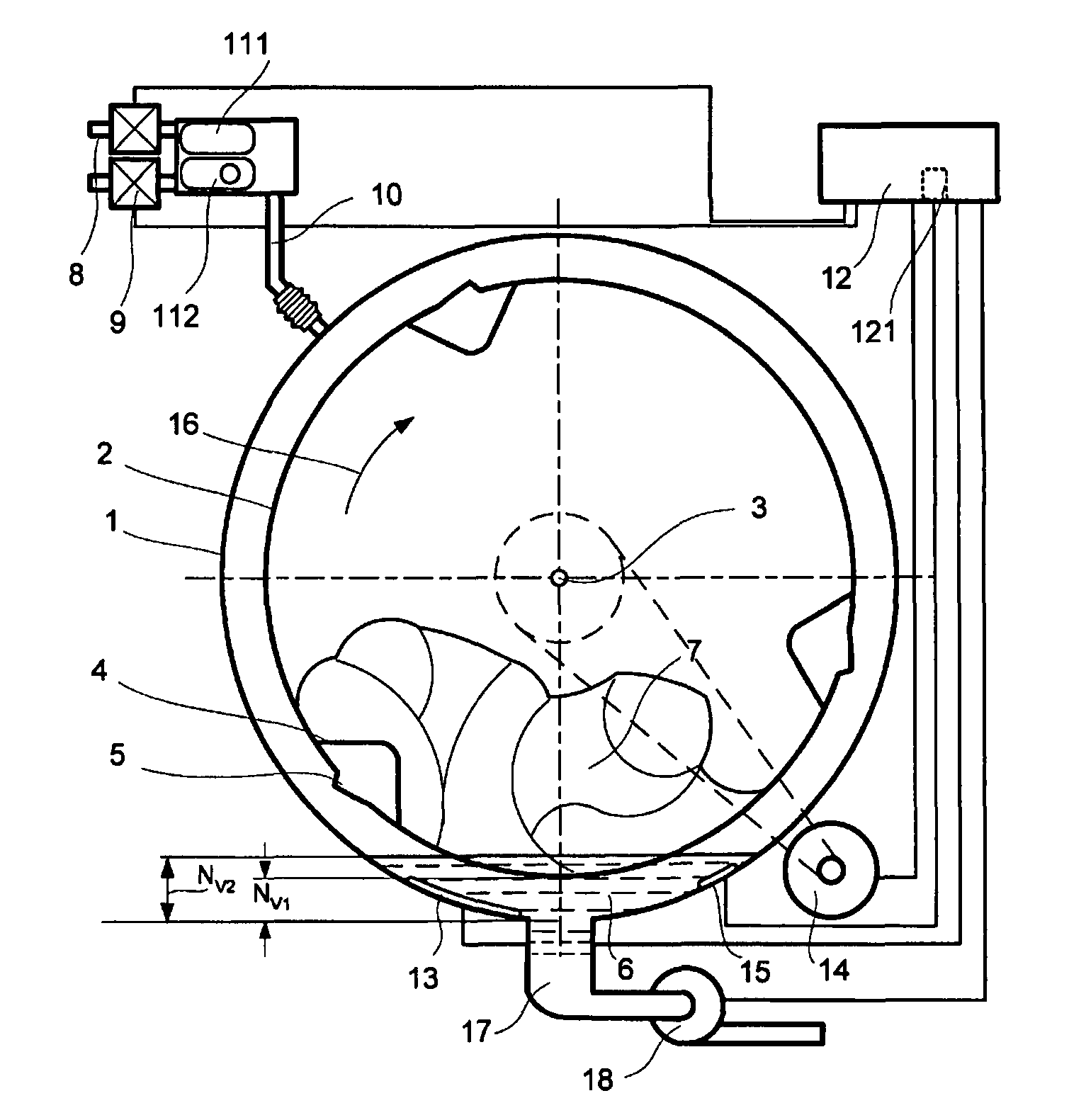

ActiveUS8313535B2Improves absorption behaviorAvoid heavy consumptionPretreated surfacesOther washing machinesProcess engineeringHydrophobic effect

A method for creating a hydrophobic effect of textiles in a washing machine. Hydrophobic agents dissolved in the washing liquid are contacted with the textiles during a treatment process. The tub is filled with an amount of water which is proportioned and which is heated to a minimum temperature in the tub while the textiles are soaked. The hydrophobic agent is flushed from the detergent storage chamber into the lye container by means of water and forms a washing liquid along with the water. The textiles are contacted with the washing liquid and are treated for a maximum of 30 minutes. The washing liquid is removed from the textiles and the washing liquid container by spin-drying without rinsing.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

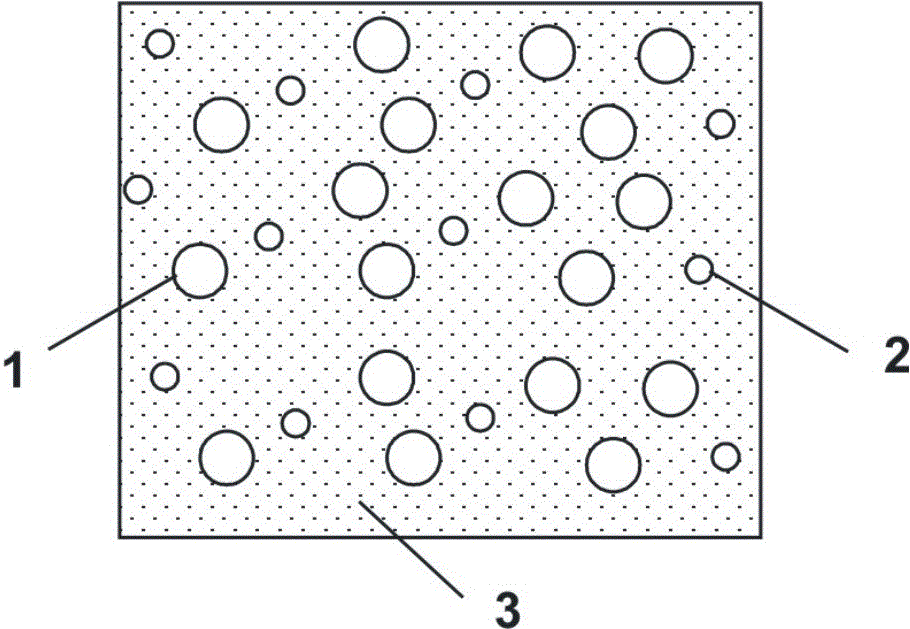

A kind of water-absorbing resin aggregate concrete and its preparation method

The invention relates to a water-absorbing swellable resin aggregate concrete and a preparation method thereof. The water-absorbing swellable resin aggregate concrete is composed of 300-420 parts by weight of cement, 186-306 parts by weight of admixtures, and 0-624 parts by weight of water-absorbing swellable aggregate. 0-954 parts by weight of fine aggregate, 87-131 parts by weight of mixing water, 11-14 parts by weight of water reducing agent, and 1.8-2.2 parts by weight of fiber are mixed by a certain preparation process. In the present invention, a spherical polymer water-absorbing resin particle whose particle size can be adjusted is used as a water-absorbing swelling aggregate, and by controlling the particle size of the water-absorbing swelling aggregate, a concrete with an adjustable internal pore structure is prepared. The inside of the concrete has a regular shape, Evenly distributed closed spherical holes, and has the advantages of low density, high strength, good performance and saving concrete solid raw materials, and the water-absorbing swelling aggregate is small in volume before absorbing water, light in weight, and convenient for transportation.

Owner:WUHAN UNIV OF TECH

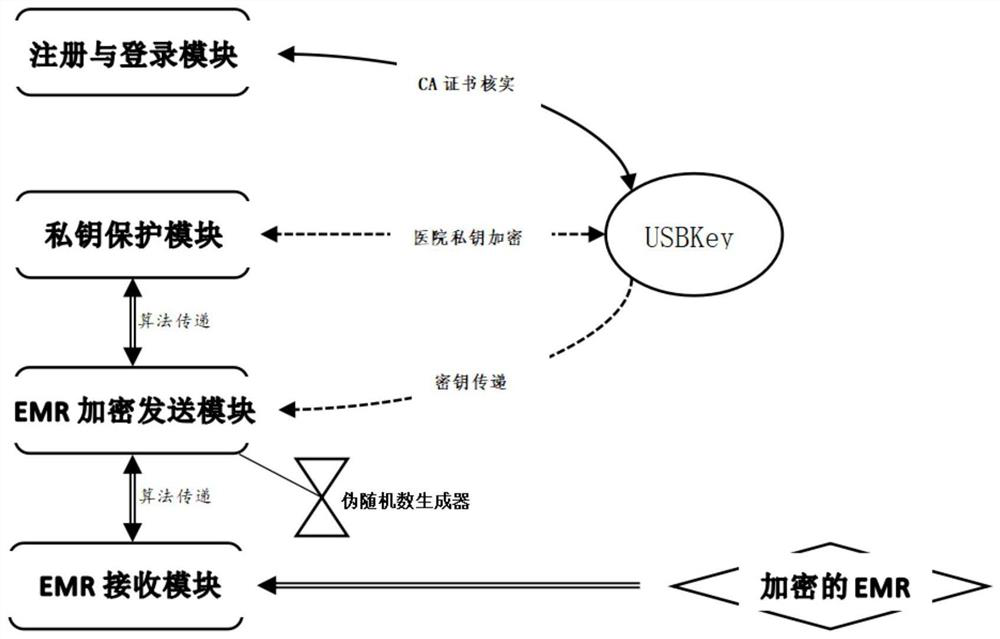

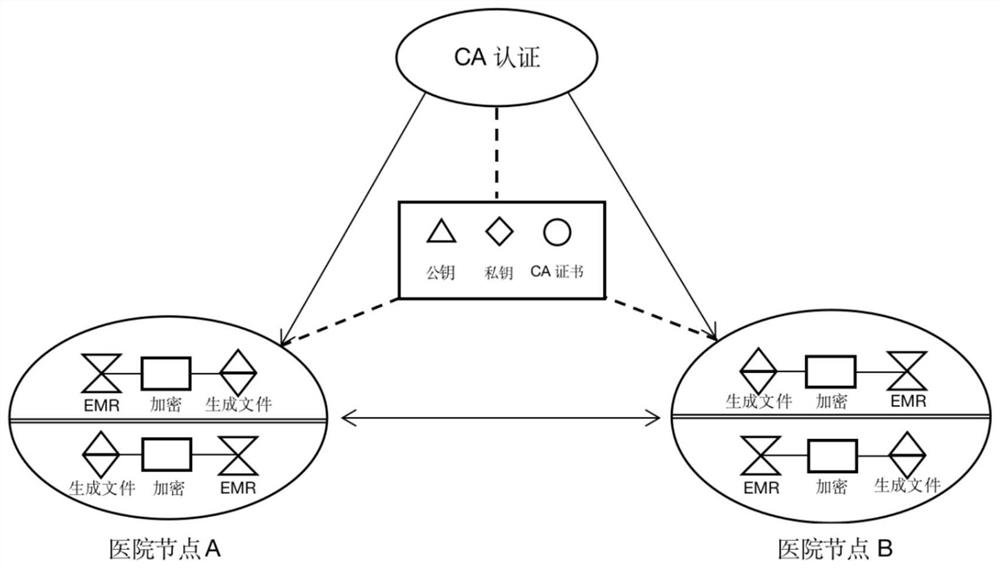

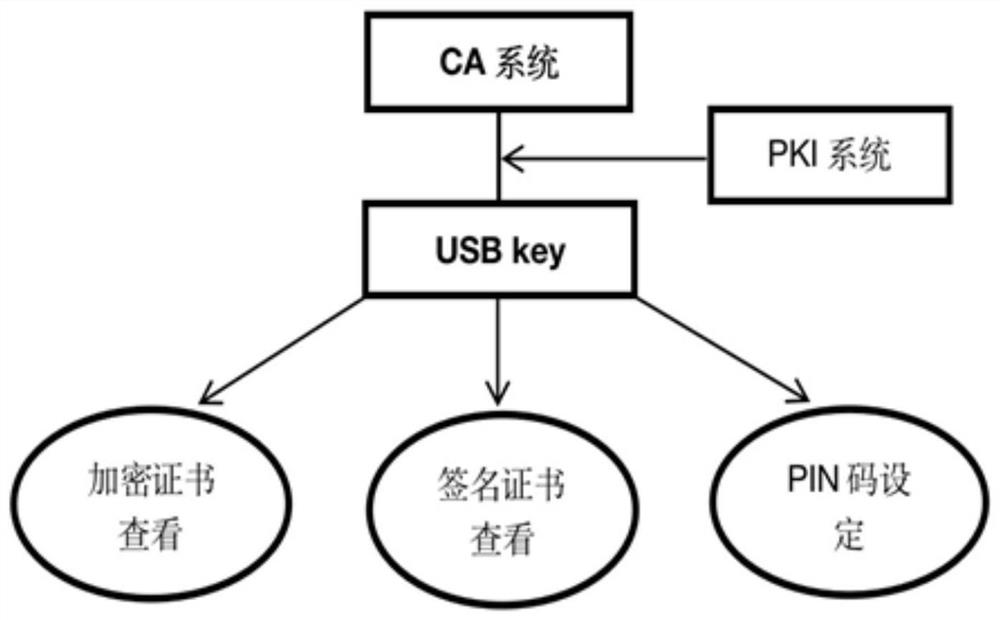

Inter-hospital electronic medical record interaction system, method and device based on PKI and storage medium

PendingCN113130031AGuaranteed reliabilityEnsure safetyDigital data protectionPatient-specific dataMedical recordEngineering

The invention discloses an inter-hospital electronic medical record interaction system, method and device based on PKI, and a storage medium. The system comprises a registration and login module, a private key protection module, an EMR encryption sending module and an EMR receiving module. Triple binding of an operator, a hospital and an intelligent terminal and triple authentication of an interaction system, the hospital and a USBKey are achieved through CA authentication, and the reliability of an electronic medical record sending source is guaranteed; a password is encrypted through a Hash salting method, and a hospital private key is encrypted through symmetric encryption, so that the security of the hospital private key during storage is ensured; through the PKI encryption technology, data can be called in real time between hospitals, data decryption is achieved at the corresponding terminals, the security of electronic medical record sharing is guaranteed when electronic medical record sharing is achieved, and the problem of information leakage is avoided; through real-time calling of the electronic medical record data, a large amount of consumption of storage resources is avoided, the data transmission speed is increased, and the problem of long transmission time consumption is avoided.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV +1

A magnetic biomimetic adsorbent and its application in the treatment of acidic uranium-containing wastewater

ActiveCN105413659BOvercoming the long preparation cycleAvoid heavy consumptionOther chemical processesRadioactive contaminantsSorbentSolvent

The invention relates to a magnetic bionic adsorbent and an application of the magnetic bionic adsorbent in treating acid wastewater containing uranium. A solvothermal method for preparing Fe3O4 by taking PSSMA (poly (4-styrene sulfonate-copolymer-maleic acid) sodium salt) as a surfactant is improved, grain sizes are uniform, and Fe3O4 magnetic nanoparticles can be synthesized on a large scale; biomolecule dopamine is polymerized in a trihydroxymethyl aminomethane buffer system and coats the surfaces of the Fe3O4 magnetic nanoparticles, and the novel magnetic bionic adsorbent with a core-shell structure is established. The magnetic bionic adsorbent has excellent hydrophilicity and larger specific surface area due to the the polydopamine structure of a shell layer, rich functional groups on the surface of the magnetic bionic adsorbent have high uranium adsorption capacity in a wider acidity range, the magnetic bionic adsorbent has higher uranium adsorption capacity and good selectivity, and uranium adsorbed on the surface of the adsorbent can be easily washed with a 0.1 mol / L (NH4)2CO3 solution and can be recycled conveniently.

Owner:TSINGHUA UNIV

Extraction process of high-purity stable red pepper pigment

An extraction process of a high-purity stable red pepper pigment is disclosed. The process is characterized by comprising following steps: a) a step of pretreating raw materials, b) a step of drying and squeezing, c) a step of flocculating and clarifying, d) a step of filtering, e) a step of extracting the filtrate and f) a step of preparing the pigment the color value of which is 40. The process adopts chitosan as a flocculating and clarifying agent, so that the product yield is relatively increased and the production cost is reduced. Polyethylene glycol which is highly safe is adopted as an auxiliary solvent, thus overcoming the problem of poor solubility of the natural red pepper pigment. The raw material utilization rate of the process is high. The prepared red pepper pigment is high in color index, good in characters, purity, stability and solubility, high in comprehensive performance cost ratio, and beneficial to popularization and application of the natural red pepper pigment in the field of foods.

Owner:QINGDAO XINRUNTU NURSERY STOCK SPECIALIZED COOP

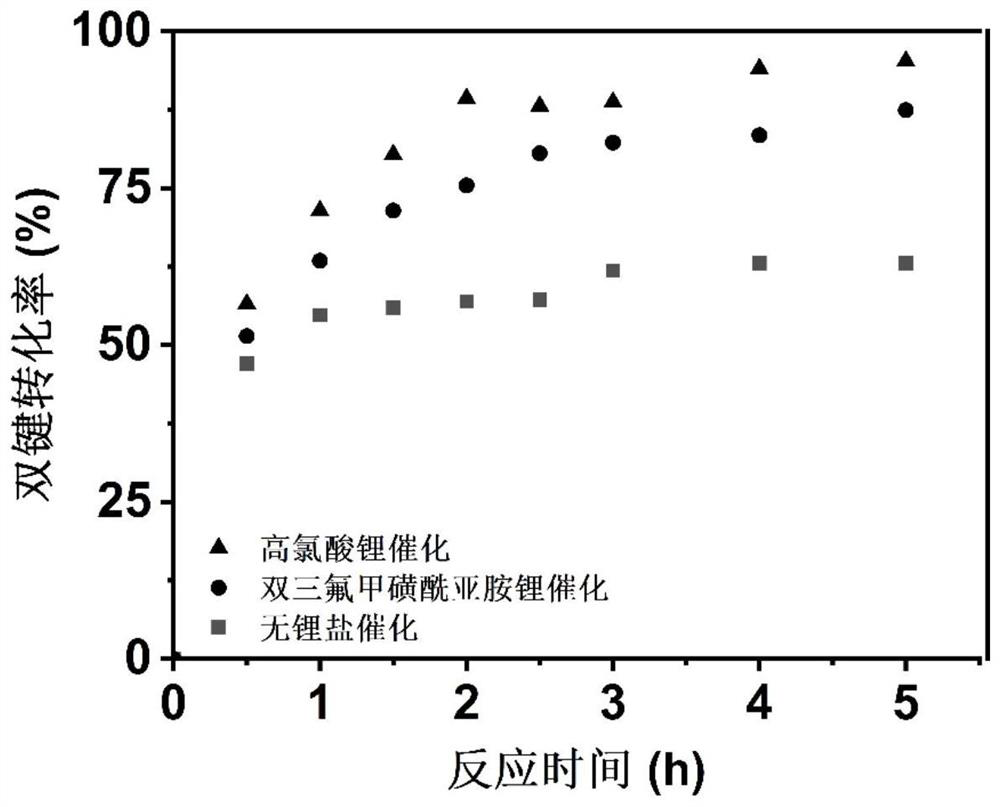

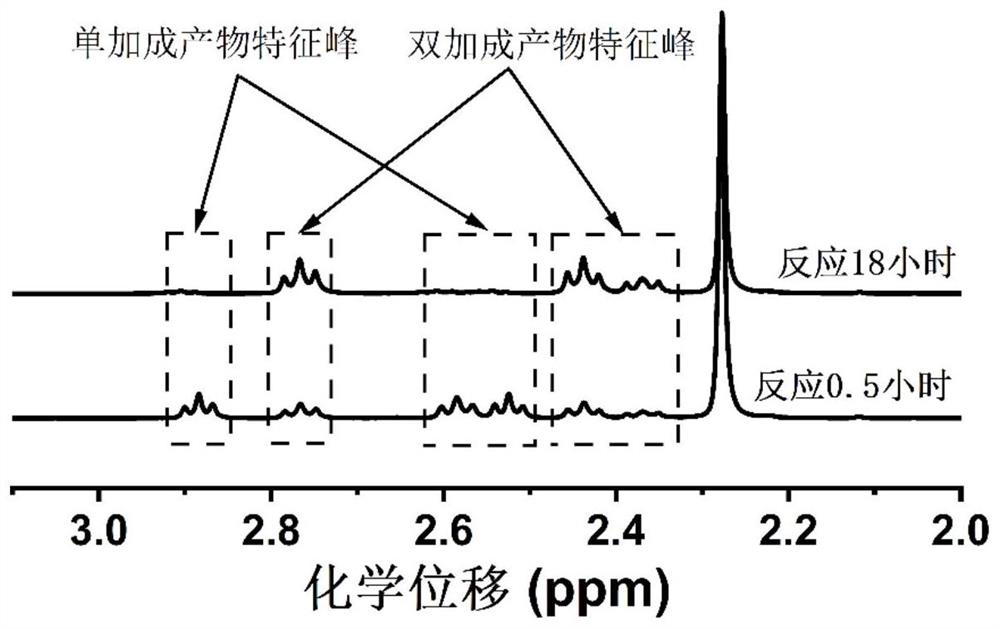

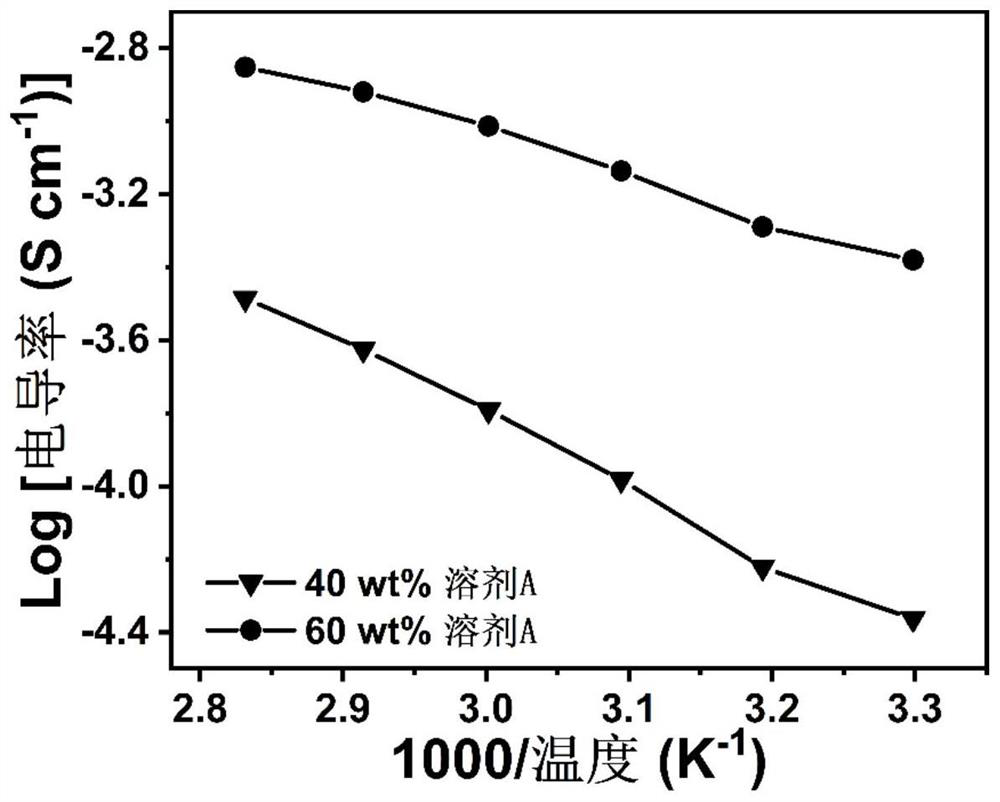

Method for catalyzing primary amine-acrylate biaddition reaction and application thereof

ActiveCN114853621AIncrease crosslink densityAvoid introducingOrganic compound preparationSecondary cellsPolymer electrolytesPtru catalyst

The invention belongs to the technical field of polymer electrolyte, and particularly discloses a method for catalyzing primary amine-acrylate biaddition reaction and application of the method. According to the method, lithium salt is introduced into a reaction system of a primary amine monomer and an acrylate monomer to serve as a catalyst; lithium ions dissociated from the lithium salt are coordinated with carboxyl in the acrylate monomer to reduce the electron cloud density of double bonds, so that a secondary amine mono-addition intermediate product generated after the mono-addition reaction of the primary amine monomer and the acrylate monomer is catalyzed to perform a second-step addition reaction; the tertiary amine biaddition product is obtained. The lithium salt is utilized to catalyze the primary amine-acrylate biaddition reaction, the reaction efficiency is greatly improved, the conversion rate is high, the gel polymer electrolyte is prepared in situ by utilizing the reaction system, the method is simple and efficient, the reaction condition is mild, and the prepared gel polymer electrolyte material is stable in structure and has excellent electrochemical performance.

Owner:HUAZHONG UNIV OF SCI & TECH

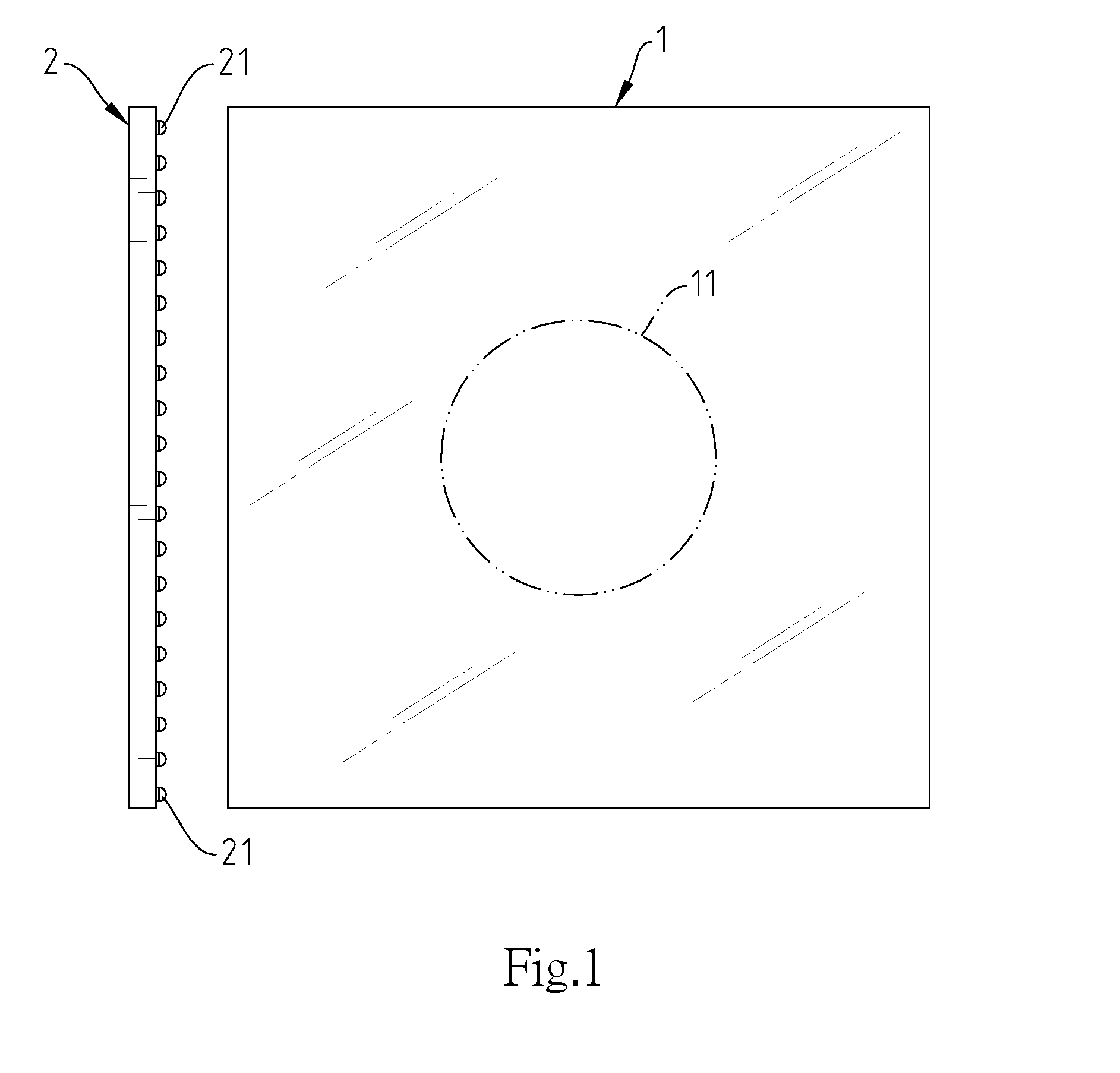

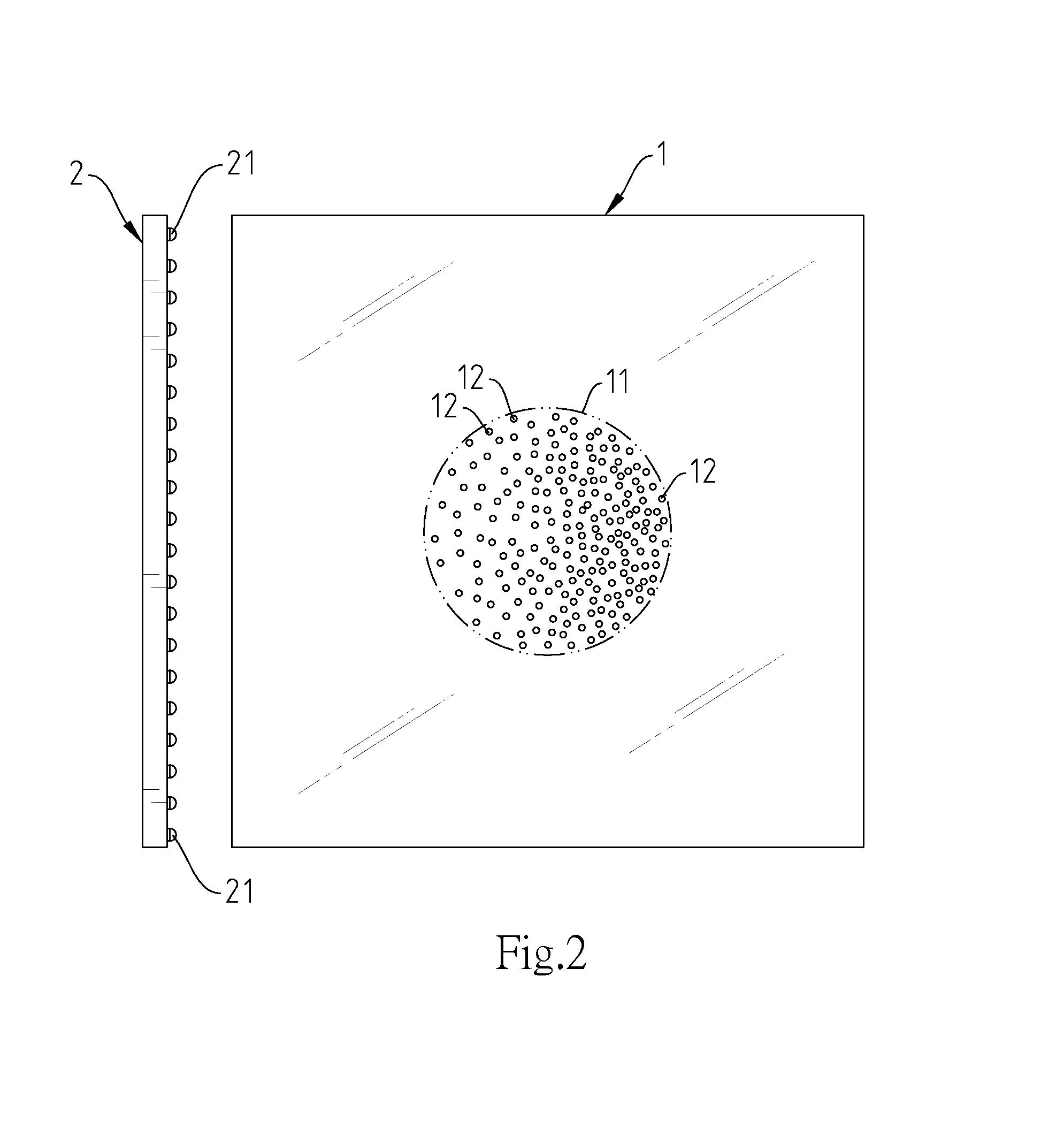

Light-emitting signboard

InactiveUS20170052310A1Avoid heavy consumptionUniform lightMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

A light-emitting signboard includes a light guide plate having a light-emitting region on a front surface thereof and a plurality of light diffusing portions located in the light-emitting region and configured to refract and diffuse light, and a light source configured to emit light into the light guide plate through one peripheral edge thereof. The total surface area of the light diffusing portions is larger than or equal to one half of the surface area of the light-emitting region, and, the density of the light-emitting regions in the light diffusing portion at the area adjacent to the light source is smaller than the density of the light-emitting regions at the area far from the light source.

Owner:LEDYOUNG TECH CORP

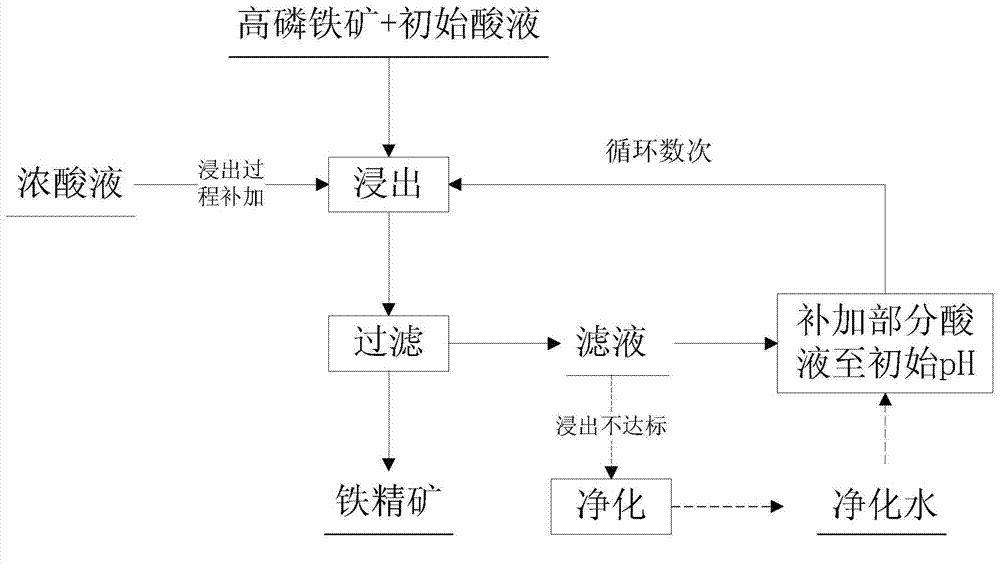

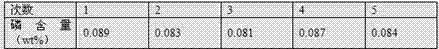

Method for removing phosphorus in high-phosphorus iron ore by virtue of acid leaching and recycling acid liquor

InactiveCN103882225AAvoid heavy consumptionAvoid pollutionProcess efficiency improvementHydrometallurgyNew materials

The invention relates to a method for removing phosphorus in a high-phosphorus iron ore by virtue of acid leaching and recycling an acid liquor and belongs to the field of wet metallurgy. The method is characterized by comprising the following steps: fine grinding and sieving the high-phosphorus iron ore, mixing the fine ground high-phosphorus iron ore with an acid liquor having a certain concentration and carrying out a leaching reaction by an appropriate constant stirring speed; after the reaction is finished, performing solid-liquid separation operation on an acid-ore suspension; after the content of phosphorus in the filter residue is detected to be qualified, directly starting a steel production process, replenishing partial concentrated acid to the filtrate to recover the initial acidity and then recycling the filtrate to leach new materials; when the recycling of the filtrate reaches the limit and the dephosphorization rate is no longer capable of meeting the production requirement, performing purification treatment on the filtrate, and directly draining the purified solution or recycling the purified solution in the acid leaching dephosphorization process. The method is simple to operate, high in dephosphorization efficiency, and capable of obtaining the iron ore with satisfying quality; besides, the method is also capable of recycling the waste acid liquor, reducing the purification times of the acid liquor, and thus saving the cost and protecting the environment.

Owner:UNIV OF SCI & TECH BEIJING

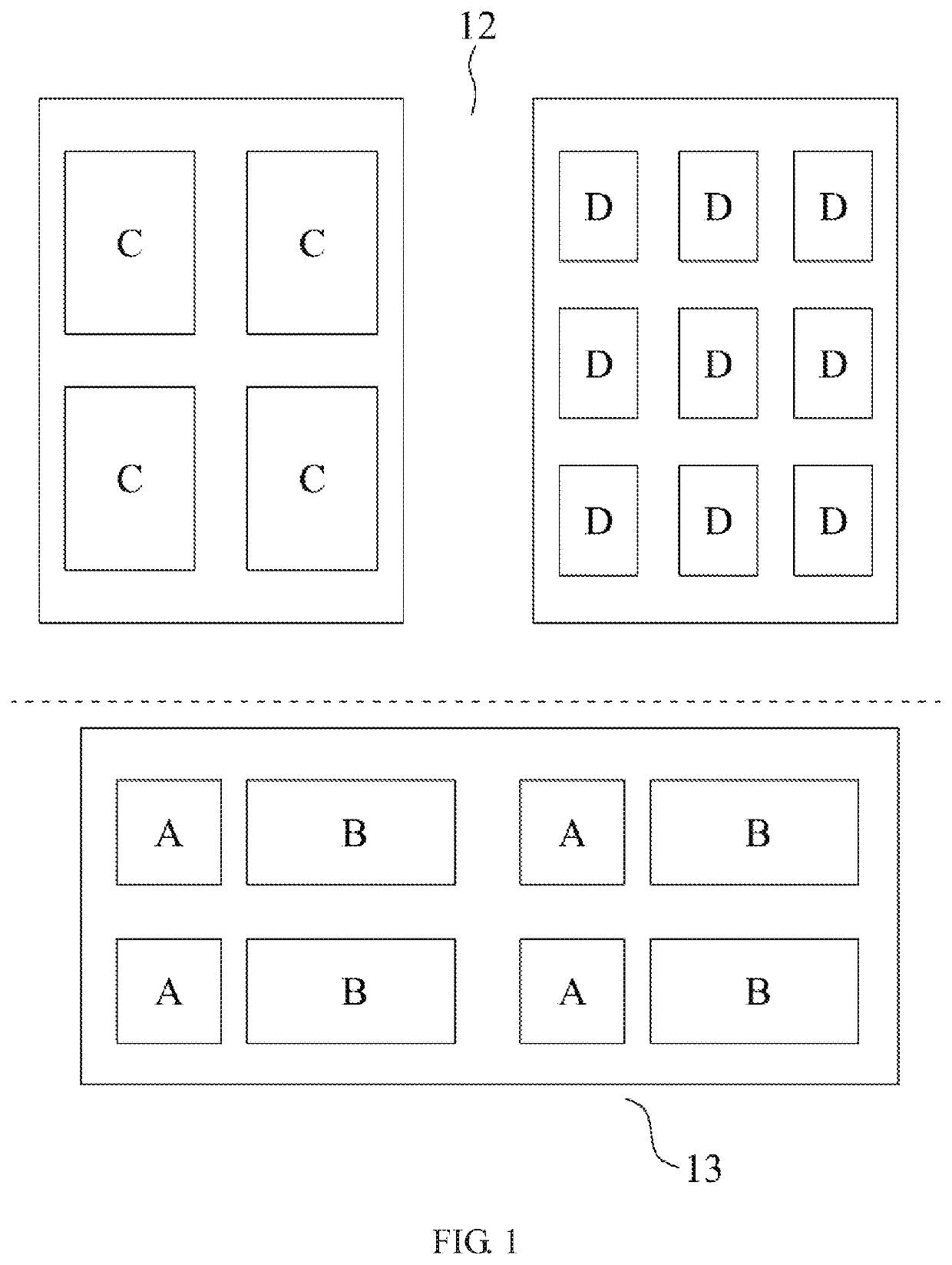

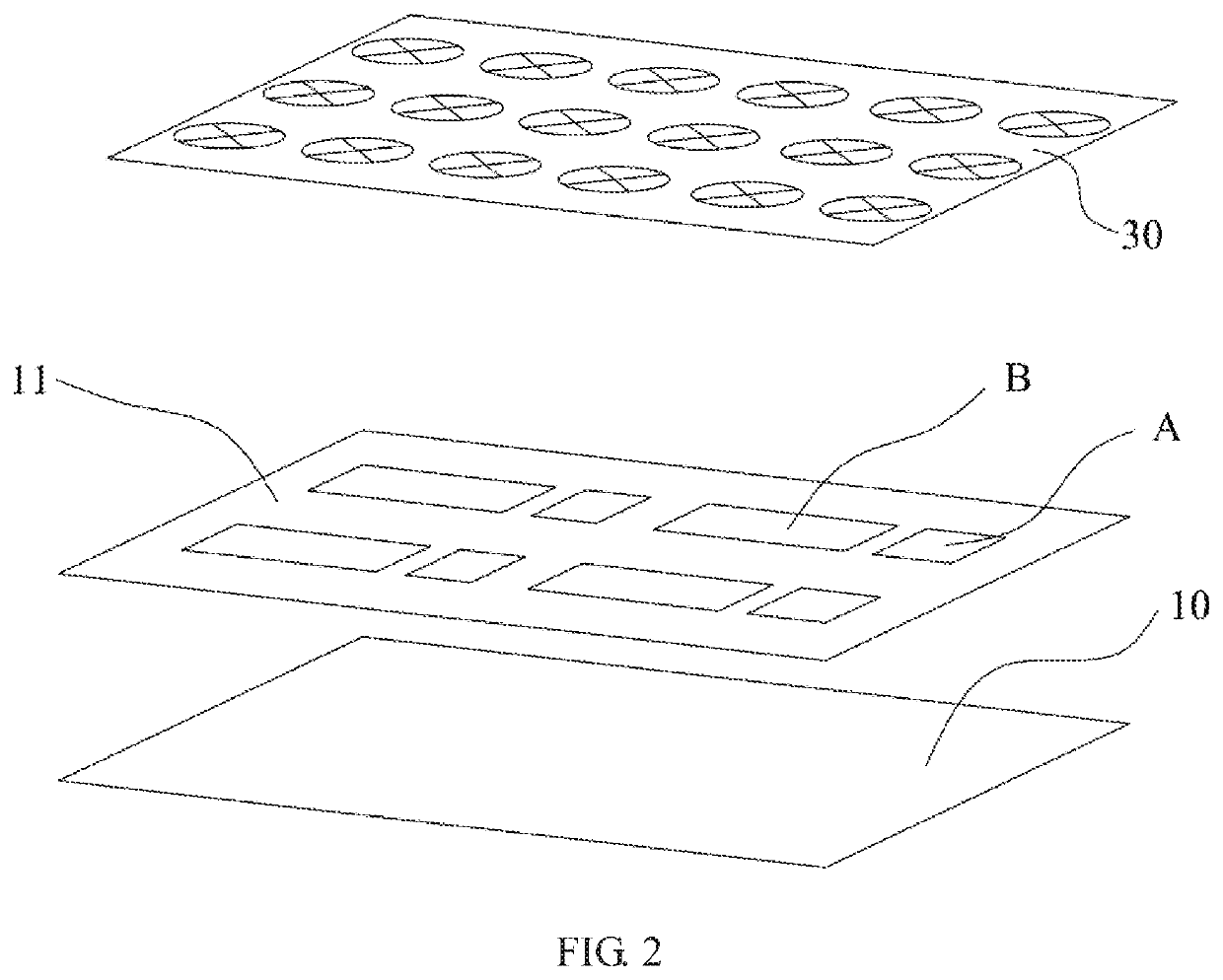

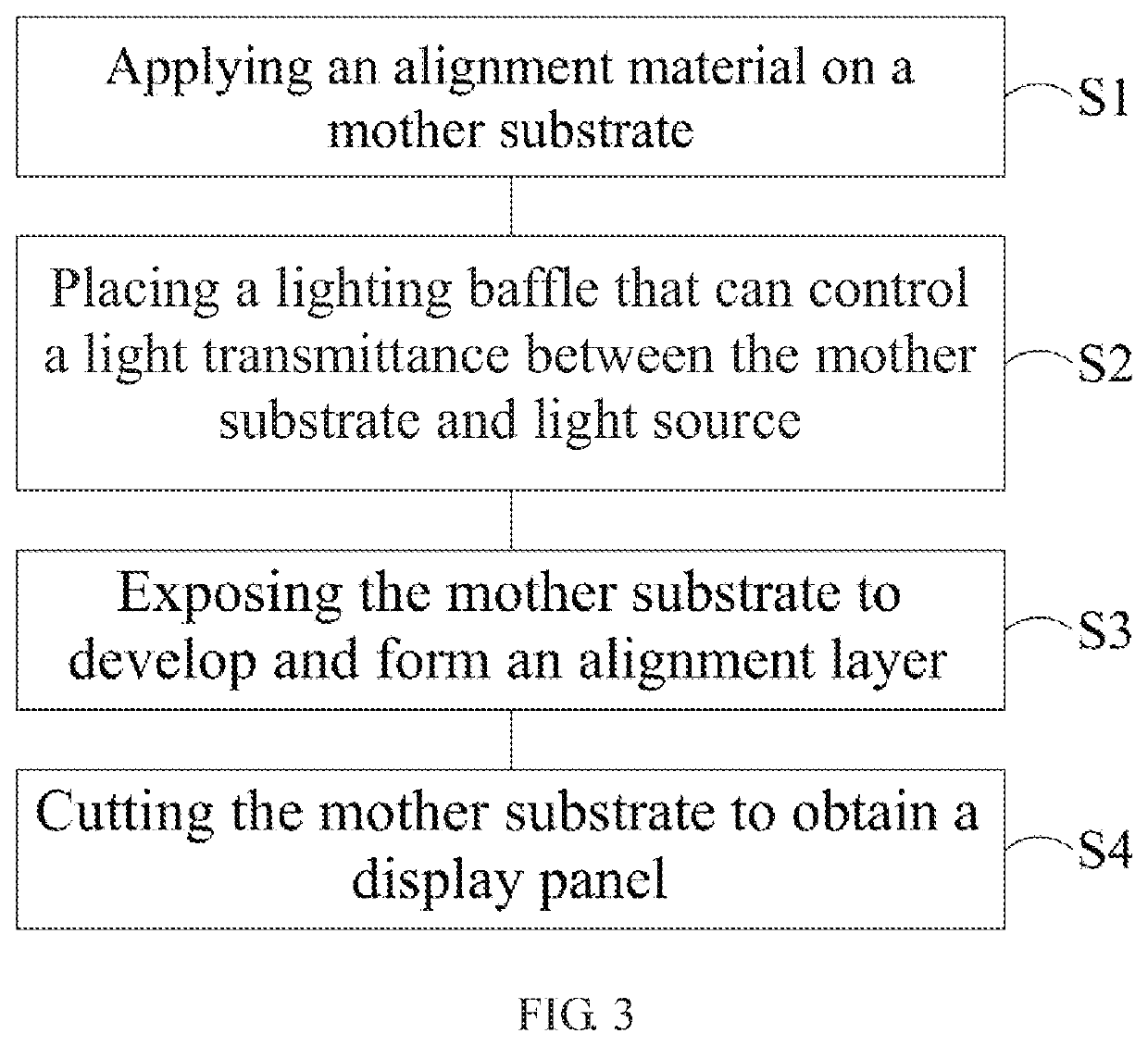

Manufacturing Method and Manufacturing Apparatus for Display Panel

ActiveUS20200363685A1Improve productivityAvoid heavy consumptionNon-linear opticsMechanical engineeringLight transmission

A manufacturing method and a manufacturing apparatus for a display panel are provided, wherein the manufacturing method include steps of: applying an alignment material on a main substrate; placing a lighting baffle between the main substrate and a light source to control the light transmittance; exposing the main substrate to develop and form an alignment layer; cutting the main substrate to obtain a plurality of display panels.

Owner:HKC CORP LTD

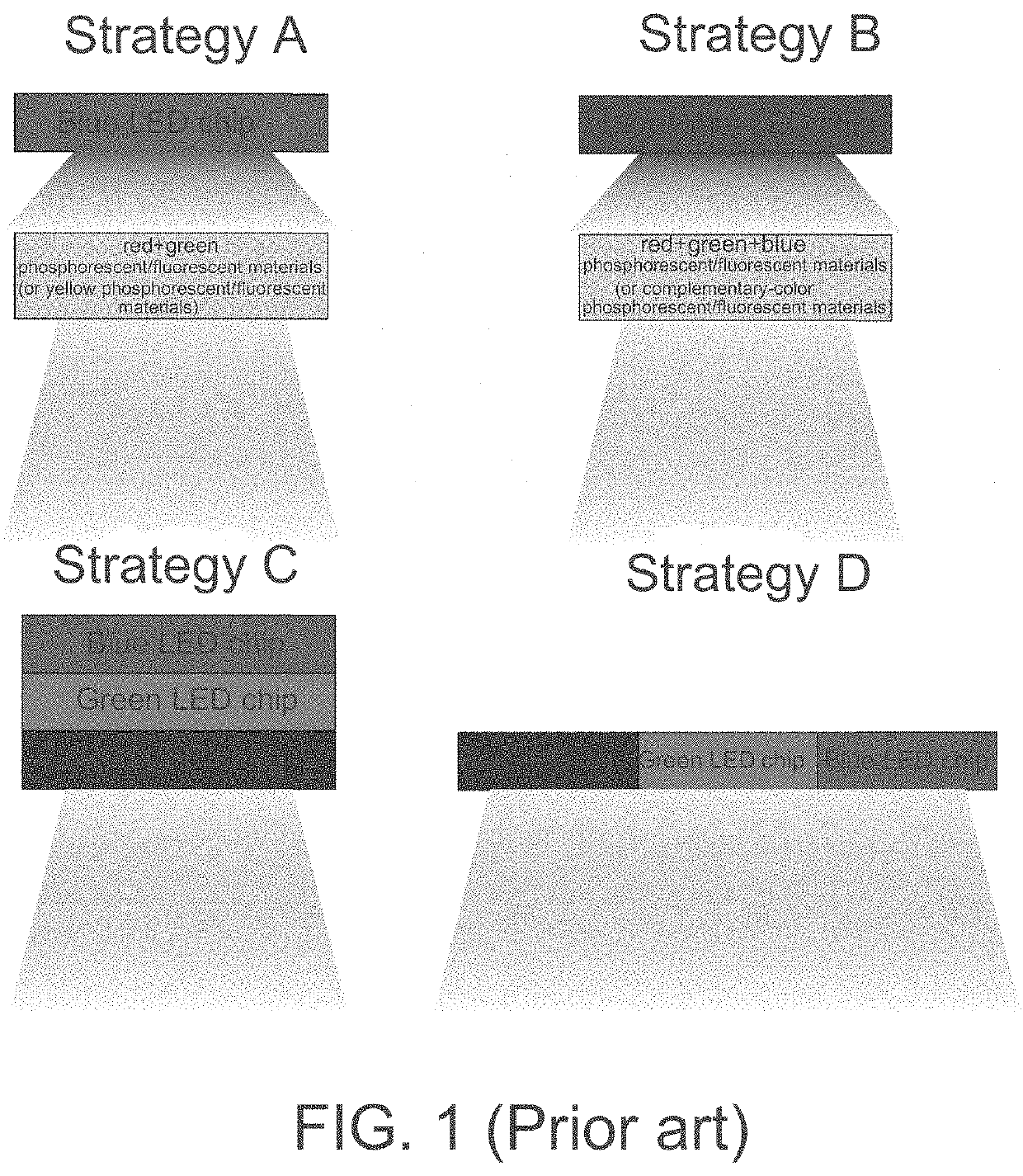

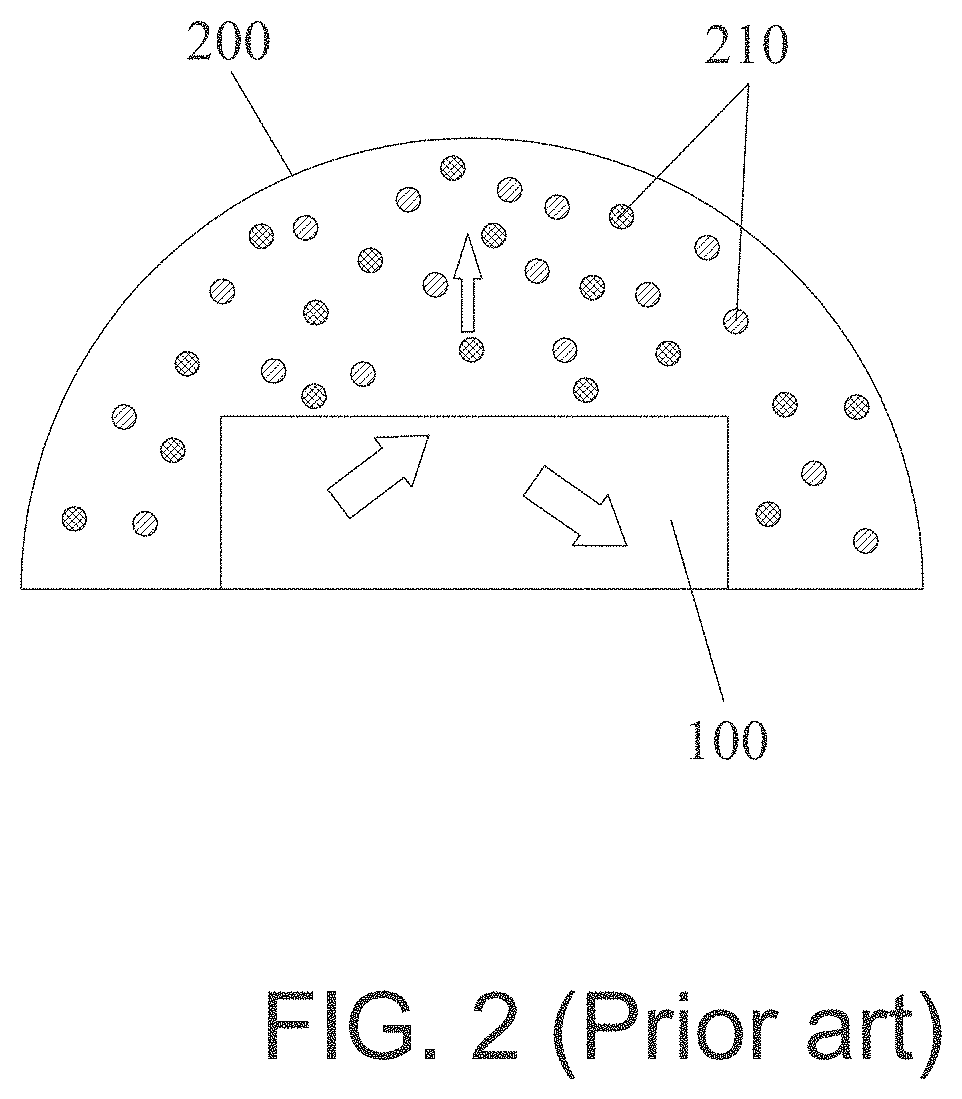

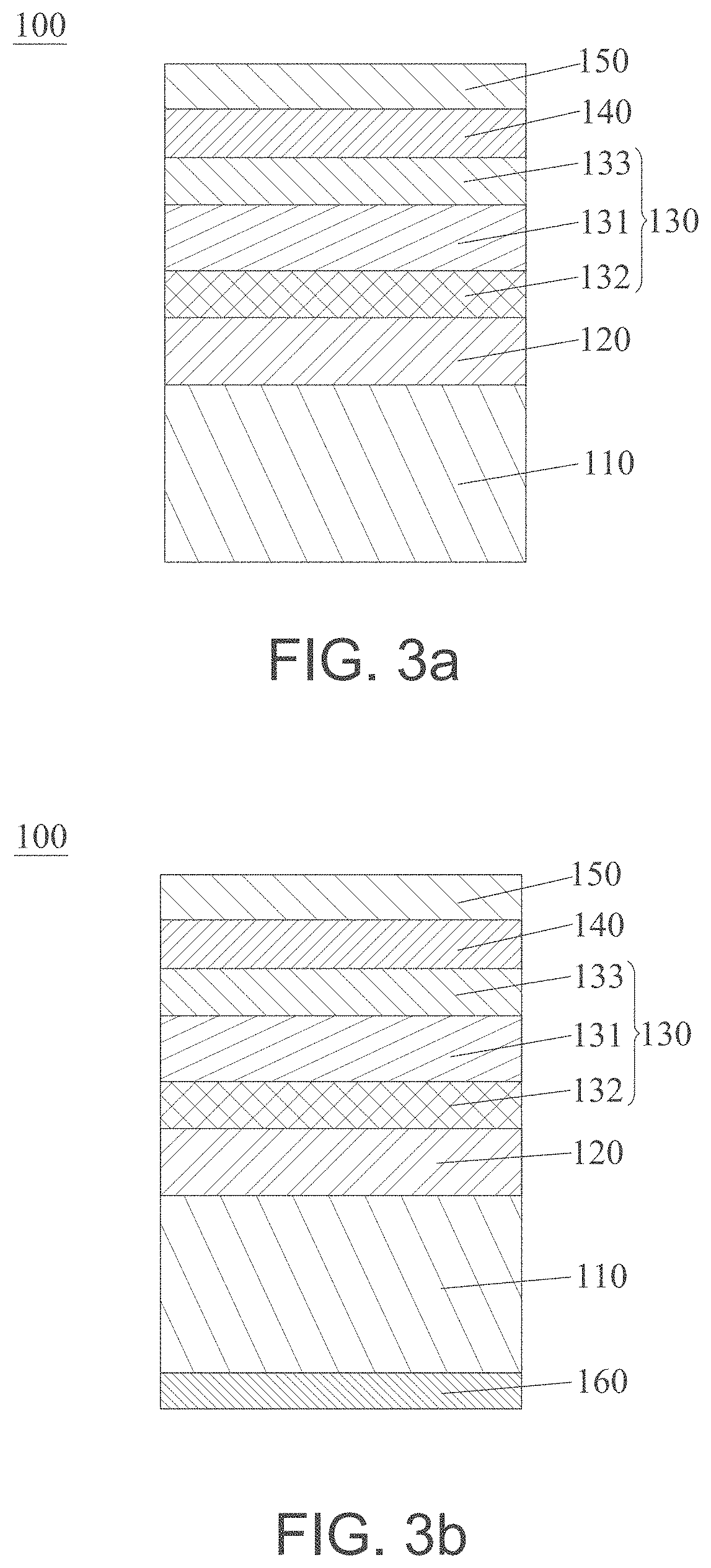

Thin-film white LED chip

PendingUS20210288224A1Improve external quantum efficiencyLighting energy consumptionSemiconductor devicesEngineeringMaterials science

A thin-film white LED chip includes a transparent substrate, a first transparent electrode, an emissive structure, a second transparent electrode, and a first phosphorescent / fluorescent layer respectively arranged in sequence. The emissive structure includes an emissive layer, an electron injection layer and a hole injection layer respectively formed at both sides of the emissive layer, and a total thickness of the electron injection layer and the second transparent electrode (in an inverted structure) or a total thickness of the hole injection layer and the second transparent electrode (in a conventional structure) is smaller than a length of one emission wavelength of the emissive layer. The evanescent wave generated by total internal reflection can penetrate into and be absorbed by the first phosphorescent / fluorescent layer to further emit light, thereby the overall external quantum efficiency of the LED chip is improved.

Owner:SOUTH CHINA UNIV OF TECH

Low free high compatibility toluene diisocyanate trimer curing agent and preparation method thereof

ActiveCN105315433BFacilitated DiffusionReduce contentPolyurea/polyurethane coatingsToluene diisocyanateAntioxidant

The invention discloses a low-free high-compatibility toluene diisocyanate trimer curing agent and a preparation method thereof. The preparation method comprises the following steps: under nitrogen protection, putting a toluene diisocyanate monomer, a solvent and an antioxidant into a reaction vessel; controlling the reaction temperature to be 10-50 DEG C at an earlier stage; adding a catalyst in batches when NCO% is 12-14wt% and 10-11wt% and reaction is started; when NCO is 9.3-10wt%, adding the residual catalyst and controlling the temperature to be 50-100 DEG C; when NCO% is 8.0-9.3wt%, adding a polymerization inhibitor, reacting for 0.5-1 h, adding a component A, reacting for 2-4 h, adding a component B, reacting for 1-2 h, stopping reaction, cooling to room temperature and discharging materials so as to obtain the toluene diisocyanate trimer curing agent with free TDI less than 0.5%, xylene tolerance larger than 3, light color, quick drying and stable performance finally.

Owner:SOUTH CHINA UNIV OF TECH

Waste treatment method of gas-phase method quartz product manufacturing process and waste treatment method of optical fiber preform rod manufacturing process

ActiveCN105753220BSolve the problem that fluoride ion is difficult to reach the standardAvoid heavy consumptionSilicon halogen compoundsWater contaminantsGas phaseFumed silica

The invention discloses a waste treatment method in the gas-phase method quartz product manufacturing process and a waste treatment method in the optical fiber preform rod manufacturing process. In the waste treatment method of the gas-phase process quartz product manufacturing process of the present invention, SiO2 micropowder is added in the first reaction container; waste liquid produced by quartz etching treatment is added in the first reaction container; H2SiF6 reacts with NaCl to generate Na2SiF6 and HCl; the HF and NaOH in the waste liquid produced by the quartz etching process react to generate NaF and water, and the H2SiF6 and NaOH in the waste liquid produced by the quartz etching process react to generate Na2SiF6 and water; Add Na2SiF6 and Na2SiF6 and NaF produced in the third reaction vessel into the fourth reaction vessel, and add Na2CO3 into the fourth reaction vessel, Na2SiF6 and Na2CO3 react to generate NaF, SiO2 and CO2. This comprehensive treatment process can completely replace the original CaF2 neutralization and precipitation process, reducing the investment in the wastewater treatment system. No residual fluoride ions. Able to achieve the goal of zero emissions from the system.

Owner:HAWK SHANGHAI ENVIRONMENTAL TECH

Method, device and system for treating landfill leachate

ActiveCN106630100BEfficient degradationHelp break downWater treatment compoundsWater contaminantsPtru catalystPalladium catalyst

The invention discloses a landfill leachate treatment method, device and system. The method comprises the technical process that based on the synergistic effect of a palladium catalyst supported on the surface of aluminum oxide and natural iron ores (including hematite, magnetite, siderite and the like), the device is fixed at the appropriate position of a reaction system, active free radicals (mainly hydroxyl radicals) are produced in site under the condition of hydrogen and oxygen leading, and contaminants including organic matter in wastewater such as leachate and dye wastewater are removed through interface mass transfer among gas, solid and liquid and relevant interface reaction. According to the organic wastewater treatment method, a good organic pollutant degrading effect is obtained through the synergistic effect of the fixedly supported palladium and the iron ores, and the continuous wastewater output and discharging process is achieved. In the organic wastewater treatment method, hydrogen and oxygen which do not participate in the reaction can be cyclically used, the fixedly supported catalyst can be repeatedly used, and the treatment cost is greatly reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

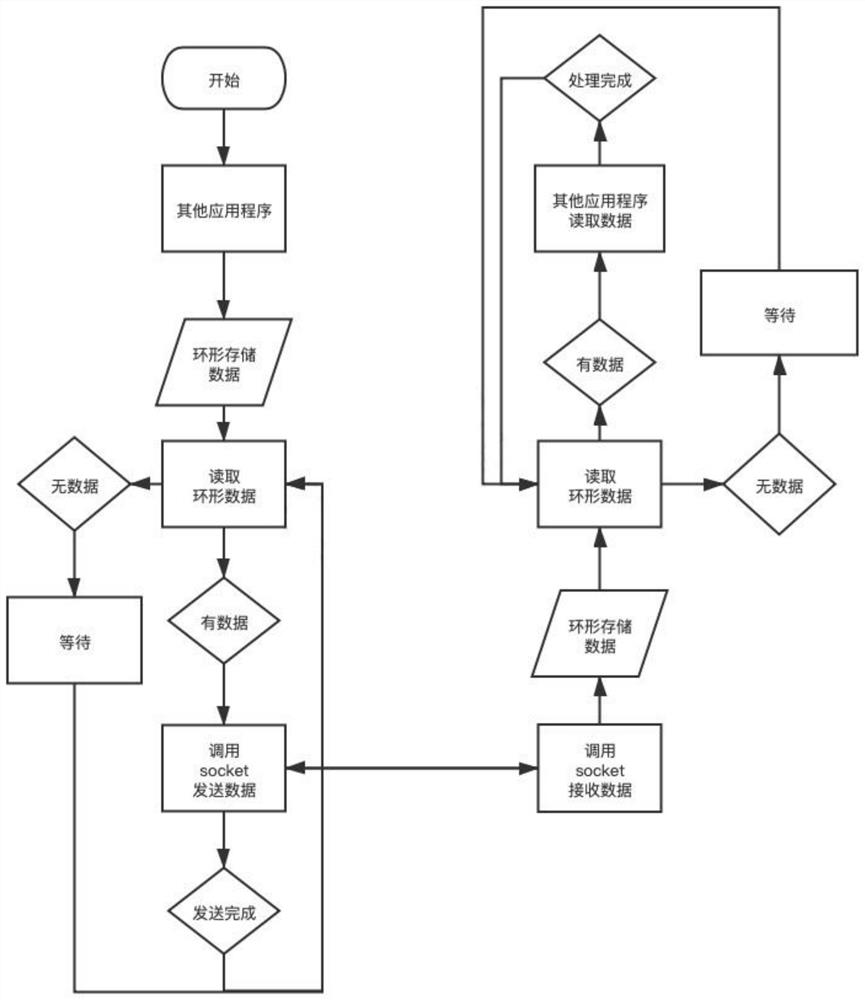

Data transmission method and system

PendingCN113438241ARealize transmissionAvoid heavy consumptionTransmissionTransport layerTerm memory

The invention relates to the field of data transmission, and particularly discloses a method and a system for realizing data transmission. By setting the socket protocol family, the data can be directly received and sent on the link layer, the data does not need to be transmitted layer by layer through the data link layer, the network layer, the transmission layer, the session layer, the presentation layer and the application layer, a large amount of consumption of system resources caused by transmitting the data layer by layer is avoided, and the data transmission efficiency is improved. Meanwhile, the risk of system crash caused by memory overflow due to data sending is also avoided; meanwhile, by arranging an annular memory of the sending end, an annular memory of the receiving end, a receiving end message confirmation data annular memory and a sending end message confirmation data annular memory, the stability and accuracy of data sending and receiving are further improved.

Owner:佳缘科技股份有限公司

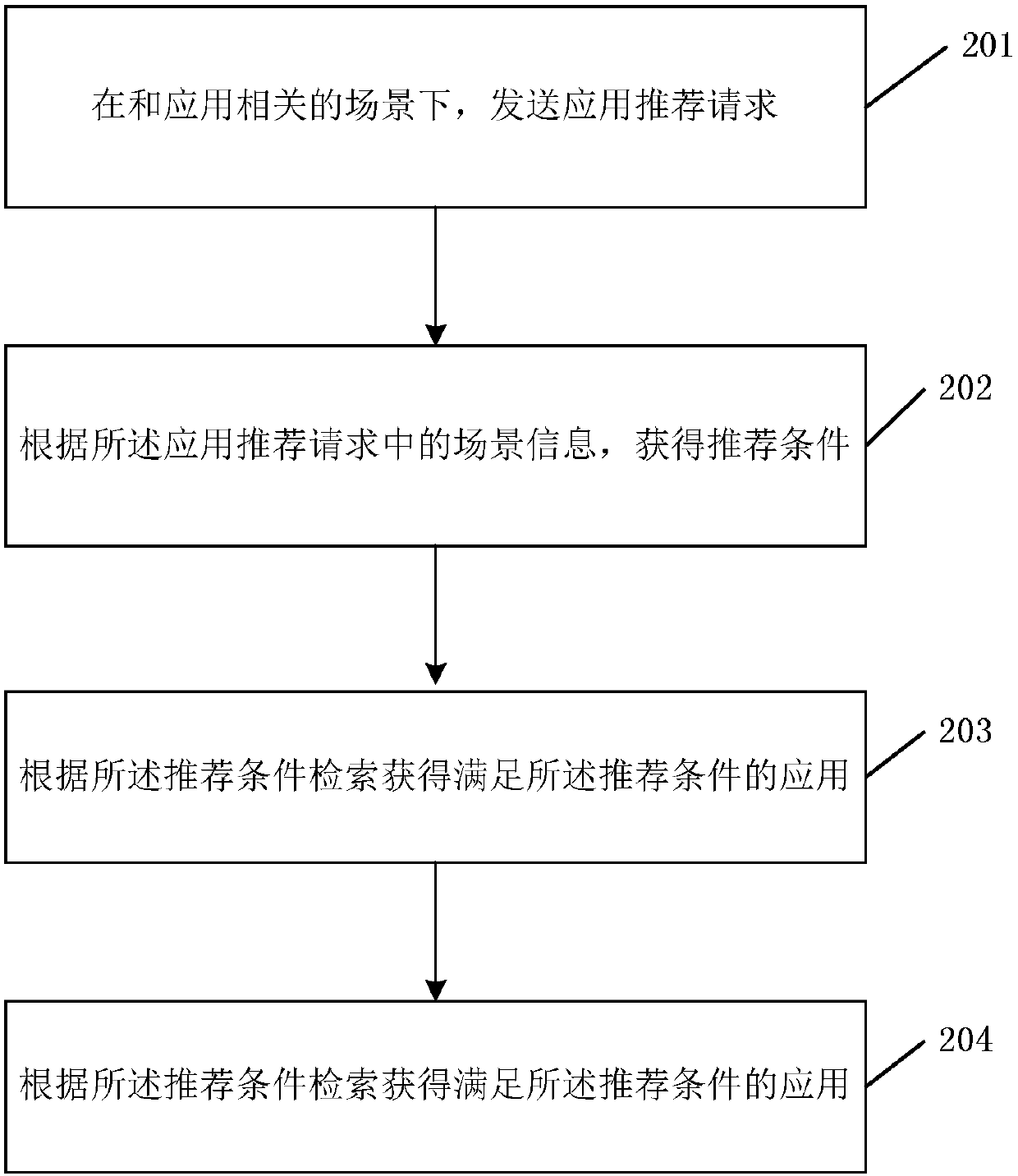

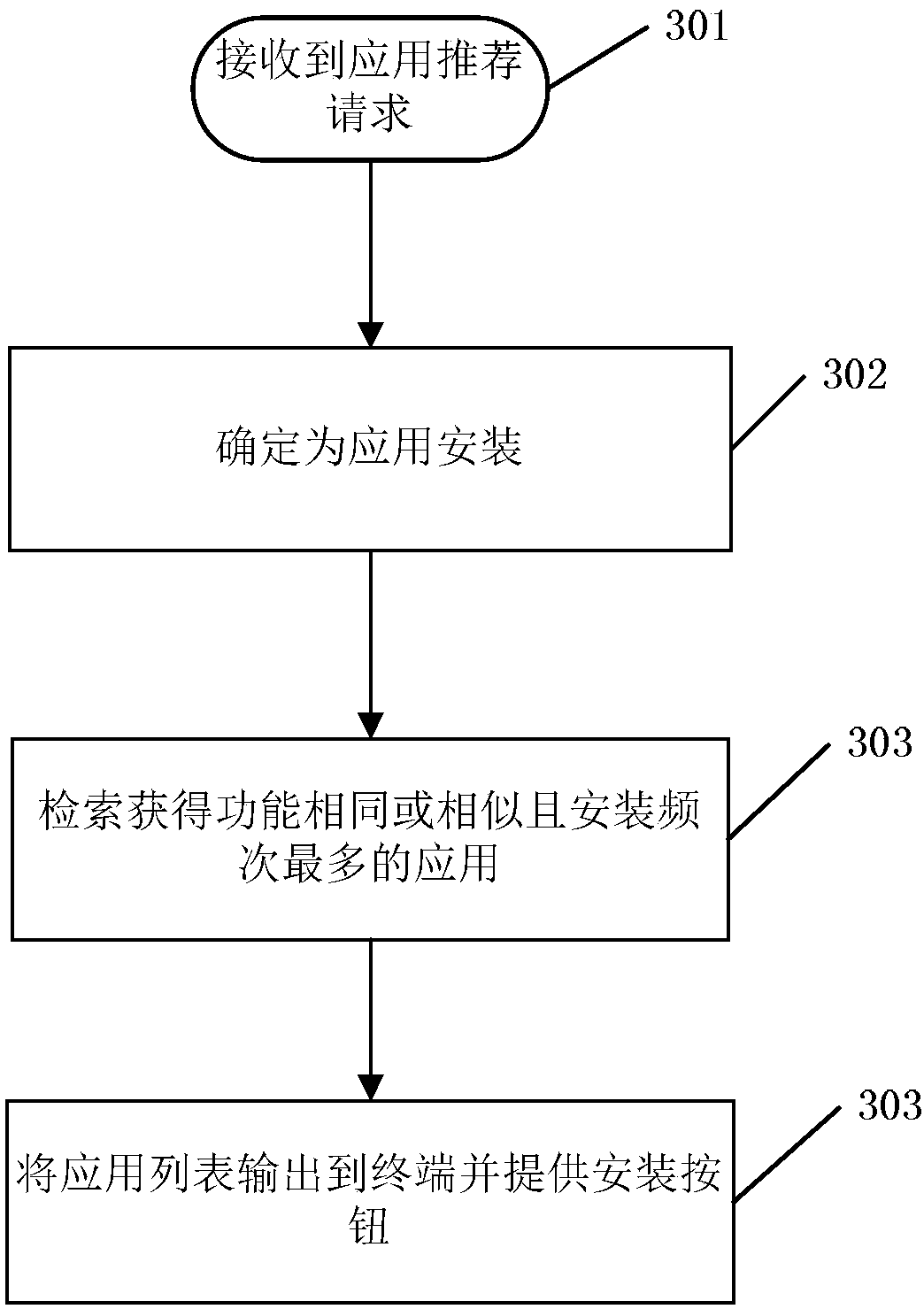

Application recommendation method and device

InactiveCN107562855AAvoid heavy consumptionApp recommendations to avoidSpecial data processing applicationsPersonalizationApplication server

The embodiment of the invention provides an application recommendation method. The method comprises the steps as follows: sending an application recommendation request in the scene related to an application; obtaining recommendation conditions based on the scene information in the application recommendation request; searching based on the recommendation conditions to obtain the application satisfying the recommendation conditions; and outputting the application satisfying the recommendation conditions to a terminal. A more personalized recommendation application list can be obtained by associating the application scene and the application recommendation; furthermore, the trigger conditions for application recommendation are set for the application in the application scene so as to avoid meaningless application recommendation and huge consumption of resources from the terminal and / or an application server side.

Owner:JIANGXI BORUITONGYUN TECH CO LTD

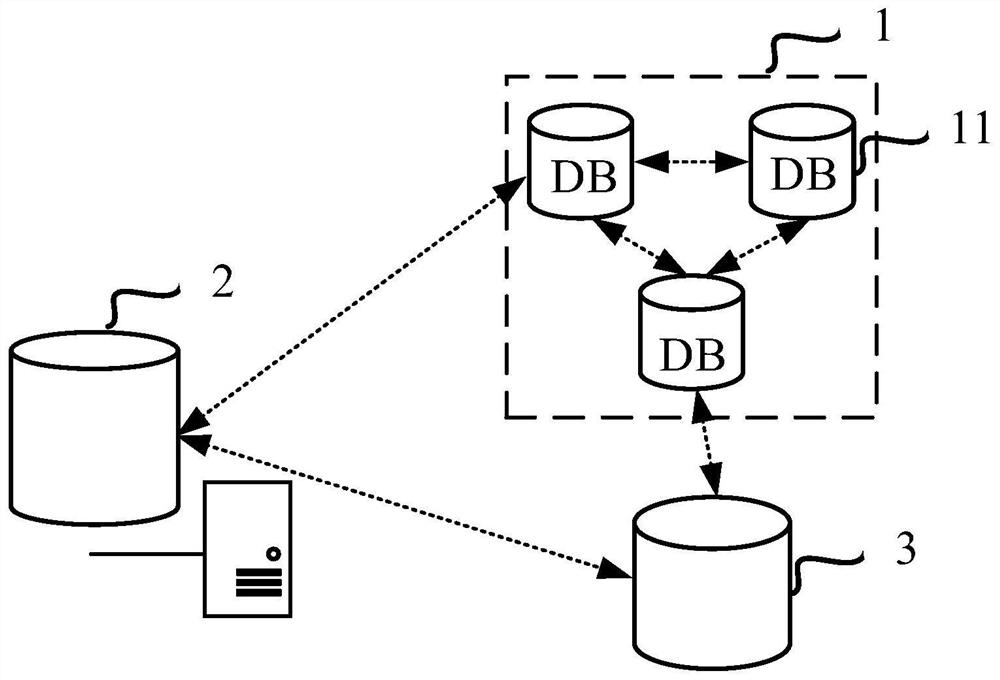

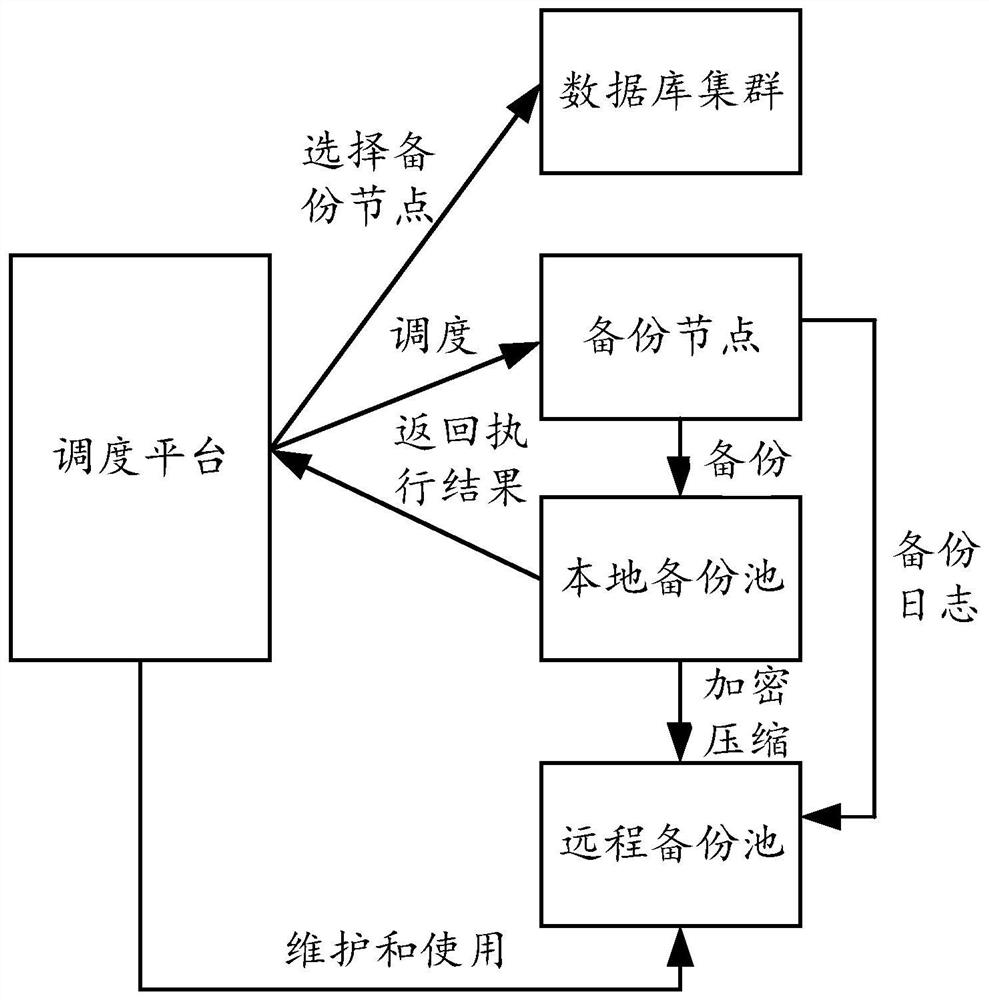

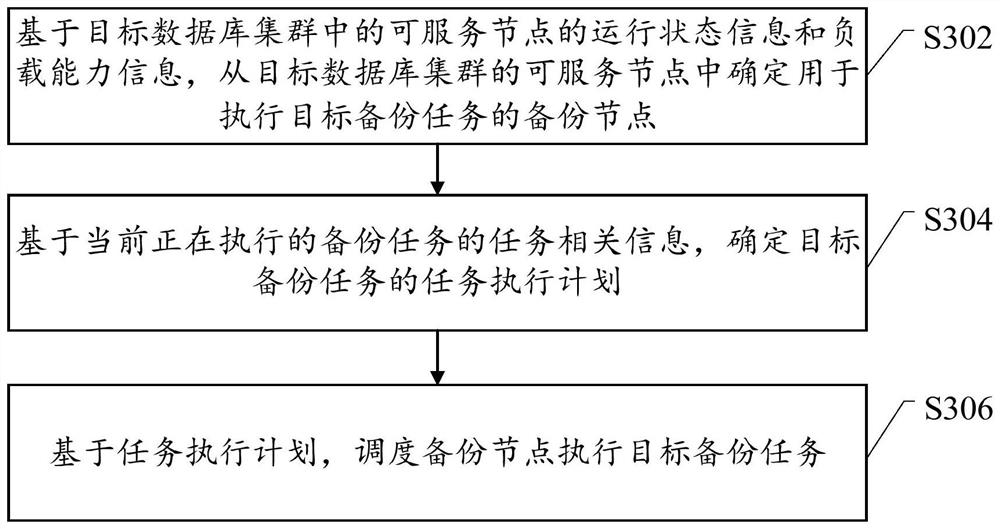

Data backup method, device and system for database cluster

PendingCN114780296AIssues affecting production and operationAvoid heavy consumptionDatabase distribution/replicationRedundant operation error correctionExecution planDatabase clustering

The embodiment of the invention discloses a data backup method, device and system for a database cluster, and is used for solving the problems of tedious backup process, low backup efficiency and success rate, influence on production and operation of the database cluster and the like in the existing backup scheme. The method comprises the steps that on the basis of running state information and load capacity information of serviceable nodes in a target database cluster, backup nodes used for executing a target backup task are determined from the serviceable nodes of the target database cluster, and the target backup task is used for backing up target data of the target database cluster; determining a task execution plan of the target backup task based on task related information of the currently executed backup task; and scheduling the backup node to execute the target backup task based on the task execution plan.

Owner:MASHANG CONSUMER FINANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com