Method, device and system for treating landfill leachate

A wastewater treatment and organic wastewater treatment technology, which is applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of low oxidant contact efficiency, inability to continuously discharge water, and a large amount of concentrated liquid. Achieve the effects of no secondary pollution, efficient and rapid degradation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

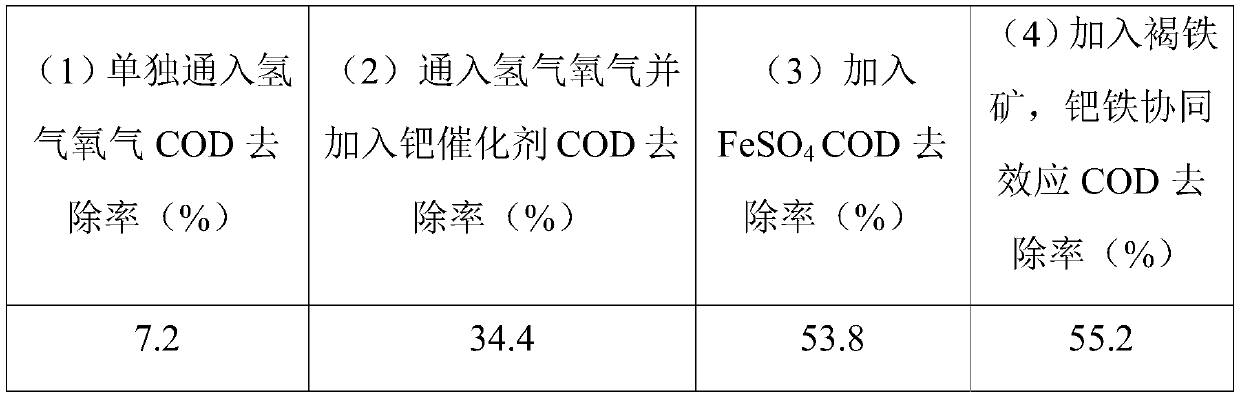

Embodiment 1

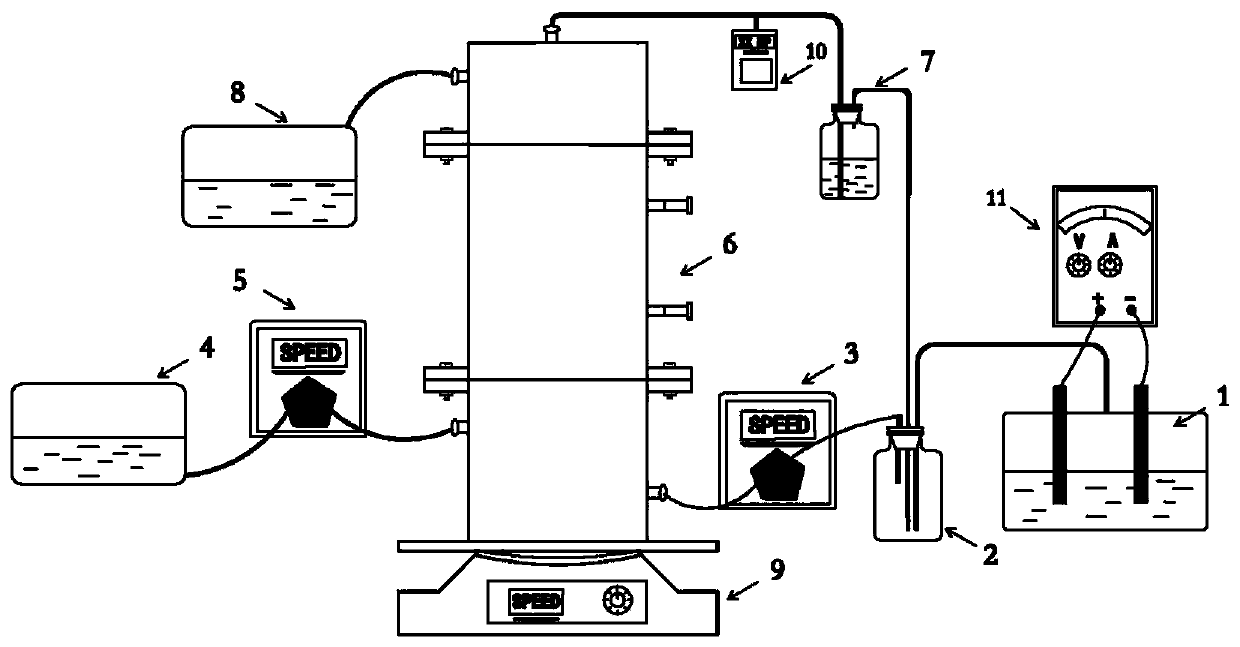

[0097] An organic wastewater treatment system, such as figure 1 As shown, it includes a gas generating device 1, a gas buffer tank 2, an air pump 3, an organic waste water storage tank 4, a liquid pump 5, a molecular hydrogen oxygen participating palladium catalytic oxidation reactor 6, a gas washing bottle 7, and an effluent collecting tank 8.

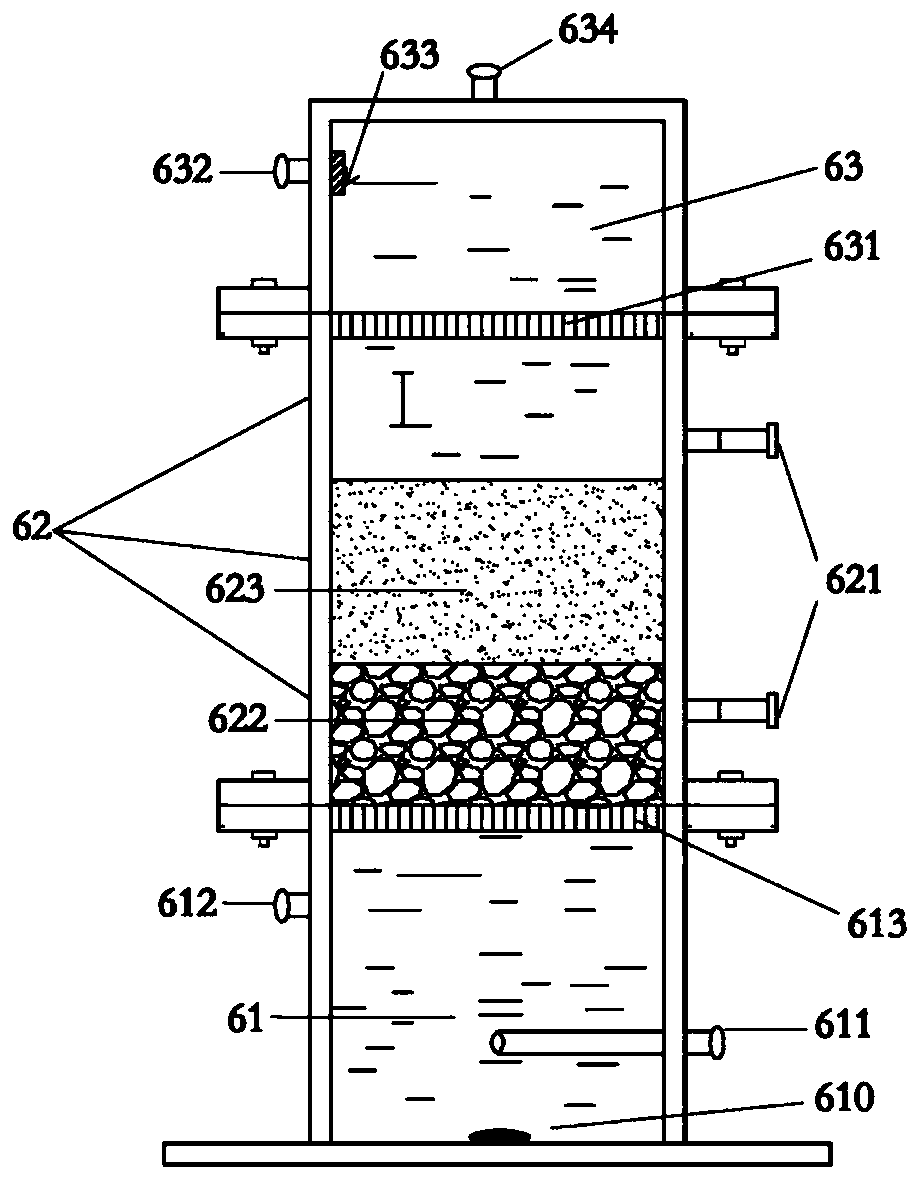

[0098] Molecular hydrogen oxygen participates in the palladium catalytic oxidation reactor 6 as figure 2 As shown in the cylinder, the molecular hydrogen and oxygen participate in the palladium catalytic oxidation reactor 6, which is made of plexiglass, and includes: a gas-liquid mixing zone 61, a catalytic oxidation zone 62 and a gas-liquid separation zone 63 from bottom to top. Bolt connection is adopted, wherein: the gas-liquid mixing zone 61 is used for mixing the gas and organic wastewater required for the reaction, the catalytic oxidation zone 62 is used for removing pollutants in the organic wastewater by catalytic oxidation, ...

Embodiment 2

[0121] The organic waste water treatment system described in Example 1 is used to process the concentrated liquid of garbage leachate taken from a municipal solid waste landfill, its COD is 950~1000mg / L, pH is 7.6~8, and other equipment and parameters are implemented with the same Example 1, using siderite, hematite and magnetite as the iron ore filler layer respectively, and the dosage is 45 grams, using sulfuric acid to adjust the pH to 3, and controlling the water inlet rate through a liquid pump to make the hydraulic retention The time (that is, the time required for the leachate to pass from the liquid inlet to the liquid outlet) is 4 hours.

[0122] By comparing the COD removal results of different iron ores, it was found that the four iron ores can all obtain higher COD removal rates, and the treatment results are shown in Table 2:

[0123] Table 2 Comparison of COD removal rates of different iron ores

Embodiment 3

[0127] The waste water treatment method and system described in Example 1 were used to treat the leachate from a municipal solid waste landfill. The COD was 391-445 mg / L and the pH was 7.6-8.2.

[0128] When the gas circulation rate (flow rate) is in the range of 10-50mL / min, a higher COD removal rate can be obtained; the results are shown in Table 4:

[0129] Table 3 Comparison of COD removal rates at different gas circulation rates

[0130] Gas circulation rate (mL / min) 10 20 30 40 50 COD removal rate (%) 30.0 39.6 46.6 47.4 54.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com