Polyamideimide and preparation method thereof

A technology of polyamideimide and maleimide carboxylic acid, applied in the field of polyamideimide and its preparation, can solve the problems of poor storage stability, difficulty in solvent recovery, environmental pollution and the like, and achieve reduction in electron density , The effect of improving heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

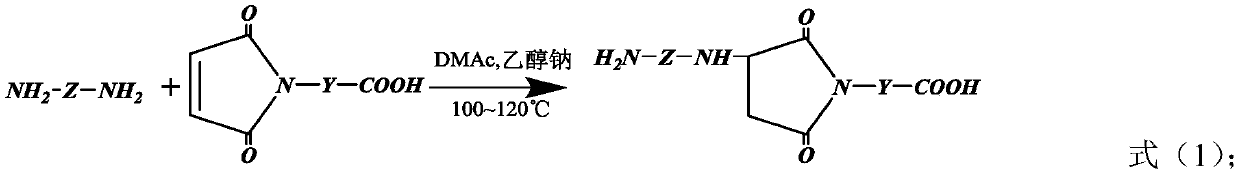

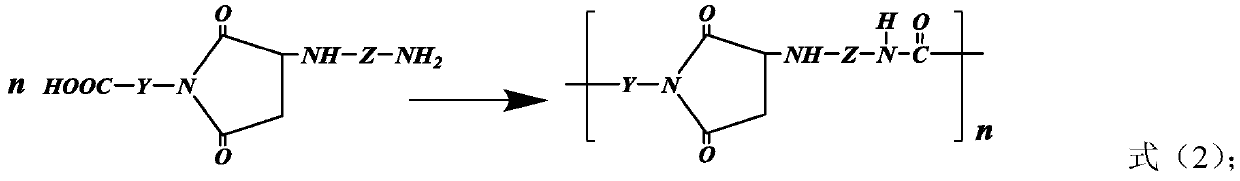

Method used

Image

Examples

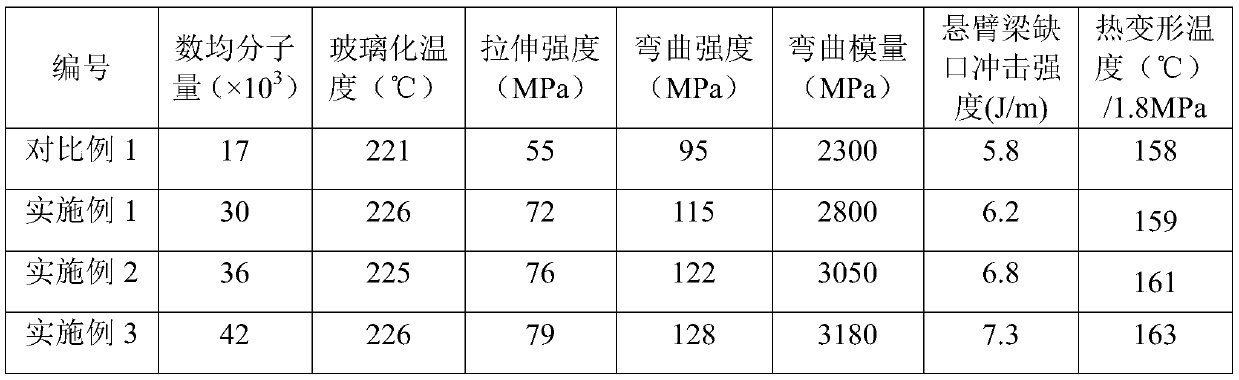

Embodiment 1

[0049] A kind of preparation method of polyamide-imide of the present invention, comprises the following steps:

[0050] (1), (2), (3) are respectively identical with (1), (2), (3) of comparative example 1;

[0051] (4) Transport the low-molecular-weight polyamide-imide to the vacuum drum for vacuum solid-phase thickening, the vacuum solid-phase thickening temperature is 220° C., and the thickening time is 12 hours to obtain the polyamide-imide of the present invention .

Embodiment 2

[0053] A kind of preparation method of polyamide-imide of the present invention, comprises the following steps:

[0054] (1), (2), (3) are respectively identical with (1), (2), (3) of comparative example 1;

[0055] (4) Transport the low-molecular-weight polyamide-imide into the vacuum drum for vacuum solid-phase thickening, the vacuum solid-phase thickening temperature is 240°C, and the thickening time is 12h to obtain the polyamide-imide of the present invention .

Embodiment 3

[0057] A kind of preparation method of polyamide-imide of the present invention, comprises the following steps:

[0058] (1), (2), (3) are respectively identical with (1), (2), (3) of comparative example 1;

[0059] (4) Transport the low molecular weight polyamide-imide into the vacuum drum for vacuum solid-phase thickening. The vacuum solid-phase thickening temperature is 220°C, the vacuum degree is -0.04MPa, and the thickening time is 18h. Invention of polyamideimide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com